CIP

Gold Carbon-in-pulp (CIP) production is the sequential leach and absorption of gold from ore. During the CIP stage, pulp flows through several agitated tanks where sodium cyanide and oxygen have been added to dissolve gold into the solution.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The CIP ( Carbon In Pulp) process is suitable for treating oxidized gold ore with low sulfur and mud content. It is unsuitable for the gold ore with high-grade silver as well. Generally, the proportion of gold and silver should not exceed 1:5. The best conditions for Carbon In Pulp process in China: PH=10-12, sodium cyanide concentration is not less than 0.015%, the particle size of activated carbon is 1.0-3.35mm, the best choice of carbon is coconut shell activated carbon, and the slurry concentration is 40-45%.

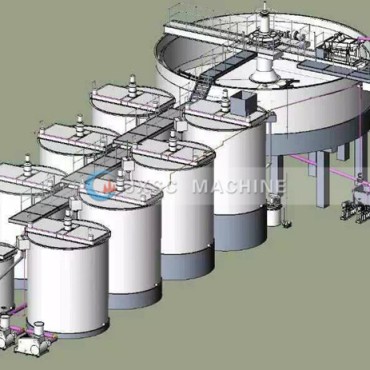

Product Structure

Carbon in the Pulp CIP Plant Consists of the Following Steps:

1. Crushing and Screening

After the crushing and screening by the crusher and vibrating screen, the bulk ore (up to 650 mm) can be broken into small sizes (about 10 mm or even smaller). Usually, small or medium-scale mineral processing plants can meet the requirements after two crushing stages and one screening stage. However, large-scale mineral processing plants need three or even four crushing stages to get qualified products.

2. Grinding and Classification

After grinding and classification, the ore material can meet the requirements of leaching (85~95% through 200 mesh). In the classical process, the grate ball mill and the spiral classifier constitute the first-stage grinding and classification unit, and the overflow ball mill and the hydro-cyclone constitute the second-stage grinding and grading unit. If the ore contains some particle gold, the gravity separation process should also be set in the first stage of grinding and grading unit.

3. Thickening

The overflow slurry of classification is only 18-25%; if directly leaching will result in excessive energy cost and reagent consumption. Therefore, thickening is a necessary step. In order to accelerate the settlement, a certain amount of flocculants will be added to enhance the thickening effect. The overflow will flow to the recycle water system, and the underflow will be pumped to the leaching tank.

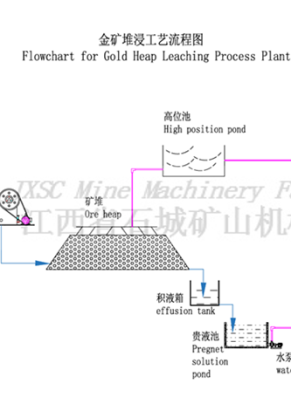

4. Leaching

After the slurry went into the leaching tank, the sodium cyanide solution was accurately added to the first leaching tank. Every stage of the tank has a certain height difference, which can let the slurry flow automatically to the next tank.

5. Adsorption

After leaching, gold is transformed from solid to free state, so a medium to enrich and recover it is necessary. Activated carbon is the best choice due to its micro-porous structure. Activated carbon is put into the slurry at the last adsorption tank and flows reversely through the air lifter. A carbon segregation screen is set in every absorption tank's outlet to separate the carbon and slurry. After screening and washing, the gold-loaded activated carbon will be sent to the desorption operation. After absorption, the gold grade in the tailing solution will reduce to 0.01-0.03g/m³.

6. Desorption of Gold-loaded Carbon and Electro-deposition

A carbon pump lifts gold-loaded carbon and slurry or air-lifted to a separation sieve (the most popular sieve is a liner vibrating sieve). Gold-loaded carbon and slurry are separated by water on the sieve surface, and then gold-loaded carbon is sent to the carbon storage tank, and the slurry and water flow into the first absorption tank.

There are several desorption methods. In China, the general application methods are the Zadra desorption method, high temperature and high-pressure desorption method (hereinafter referred to as HTHP method), and integral pressure desorption method (hereinafter referred to as IP method).

Technical Parameters

The parameters of each equipment are selected according to the processing capacity of the concentrator.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.