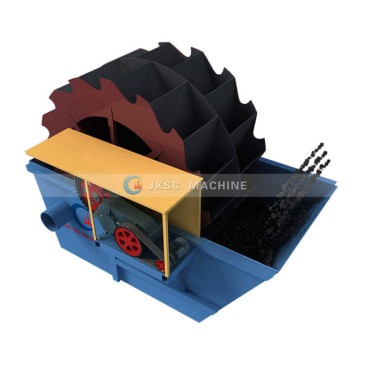

Sand Washing Machine

【Capacity】 1-400 TPH

【Types】Wheel type and spiral type sand washing machine

【Procesible Material】 Ore, natural sand and gravel, manufactured sand, etc.

【Application】 Metallurgy, ore washing plant, quarry, stone crusher plant, building materials, road construction, concrete washing, and other sand and gravel plants.

【Service】 Design and build sand washing plant, working site visiting.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

JXSC supplies two types of sand washing machines (wheel and spiral type), popularly used in mining and quarrying sites. The sand washing machines have the function of washing, classifying, removing impurities, and draining, with good effect on aggregate, sand & gravel, and ores. They usually work with sand-making machines, vibrating screens, and dewatering screens, to prepare clean ore or gravel for further processing.

The wheel sand washing machines are divided into single, double, and three bucket-type sand washing machines. Wheel bucket sand washing machines are used for washing, selecting, and dehydrating construction sand and gravel. It is necessary equipment for water-washed sand-making used with the sand-making machine. It can wash away trace amounts of stone powder and impurities from the mixed sand produced by the sand-making machine, thereby improving the quality of the sand. The machine has high cleanliness, reasonable structure, large processing capacity, low power consumption, and low sand loss.

The spiral sand washing machine is called the spiral sand washer or screw sand washer. Due to the different number of spirals inside the spiral sand washing machine, it can be divided into single spiral sand washing machine and double spiral sand washing machine. There is only one spiral inside the single spiral sand washing equipment and double spiral sand washing machine. There are two spirals inside the device.

【Advantages of Sand Washer】

- Reasonable structure

- Convenient maintenance

- Processing capacity

- Small power consumption

- Good cleaning effect

【Sand Washing Plants】JXSC Sand Washing Plants process the crushed stone & sand from the raw state to the product by a series of processes, typically including feed preparation, attrition, scrub, screening, deslime, washing, classifying, dewatering, etc. The washed sand specifications vary depending on the application, and the output requirements. The sand washing process combines a variety of equipment including attrition cells, a ball mill, rotary scrubber, vibrating screens, centrifugal slurry pumps, cyclones, separators, deslimer, dewatering screens, etc.

JXSC sand washing machine manufacturer has always provided sand washing equipment for mines, quarries, and concrete batching plants. Contact us to discuss customizable sand washing plant design and sand plant costs. Related products: sand-making machine, bucket wheel sand washer, log washer, sand screw washer.

【Sand Washing Machine Price】Factory price! The sand washing machine price is efficient and economical, relatively low price. Factory direct sale, perfect after-sales service, on-site installation.

Product Structure

【Rotary Sand Washer Structure】Main part includes feeding, bucket wheel, reducer, motor, washing tank, screen, discharging.

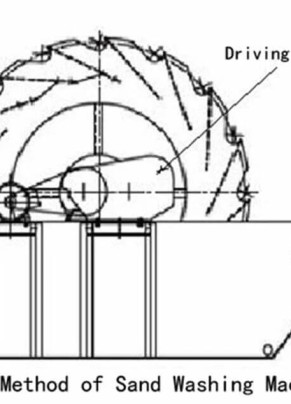

【Sand Washing Machine Working Principle】The motor drives the impeller to rotate slowly, and the sand and stones roll under the motion of the impeller and grind to each other to remove the impurities covering the surface of the sand. The flush water carries away the impurities, and the washed sand and stones are discharged continuously.

【Sand Washing Machine Manufacturer】 JXSC provides different sand screening and washing machines according to different sand washing process practical conditions, including industrial washing plant, small sand washing machine, mobile sand washing plant, support sand washing machine design, washing efficiency test.

【Sand Washing Method】1. Sand-making machine, rod mill to reduce natural material size 2. Primary classification by screw screen 3. Attrition scrubber 4. Secondary classification by spiral washing equipment or wheel bucket washer.

Technical Parameters

Wheel Type Sand Washing Machine Parameter

| Model | Dia of The Wheel Bucket (mm) | Speed of Rotation (r/min) | Maximum Feeding Size (mm) | Capacity (t/h) | Motor Power(kW) | Overall Dimensions (mm) | Weight(KG) |

| XS22-2 | 2200 | 2.5 | ≤10 | 15-30 | 4 | 3180*1955*2350 | 2260 |

| XS26-2 | 2600 | 2.5 | ≤10 | 20-50 | 5.5 | 3515*2070*2672 | 2500 |

| XS28-3 | 2800 | 1.2 | ≤10 | 50-80 | 11 | 3964*3014*2895 | 3200 |

| XS28-4 | 2800 | 1.17 | ≤10 | 60-100 | 15 | 3964*2137*2895 | 3880 |

| XS30-4 | 3000 | 1.2 | ≤10 | 120-200 | 15 | 4169*3456*3055 | 4350 |

| XS32-3 | 3200 | 1 | ≤10 | 100-160 | 15 | 4340*2760*3349 | 3950 |

| XS32-4 | 3200 | 1.17 | ≤10 | 150-250 | 18.5 | 4346*2198*3345 | 4885 |

| XS36-4 | 3600 | 1 | ≤10 | 200-350 | 37 | 4580*3218*3600 | 7500 |

Spiral Type Sand Washing Machine Parameter

| Model | Screw Diameter (mm) | Screw Number | Feeding Size (mm) | Capacity (t/h) | Water Consumption (m³/h) | Power (kw) | Overall Dimensions (mm) |

| XL-750 | 750 | 1 | <10 | 20-40 | 9-60 | 7.5 | 7000*950*1330 |

| 2XL-750 | 750 | 2 | <10 | 50-70 | 18-120 | 2*7.5 | 7000*1750*1330 |

| XL-1000 | 1000 | 1 | <10 | 50-80 | 10-70 | 11 | 8070*1200*1638 |

| 2XL-1000 | 1000 | 2 | <10 | 100-150 | 20-140 | 2*11 | 8070*2250*1638 |

| XL-1200 | 1200 | 1 | <20 | 100-120 | 20-140 | 18.5 | 9070*1430*1900 |

| 2XL-1200 | 1200 | 2 | <20 | 150-180 | 40-280 | 2*18.5 | 9070*2700*1900 |

| XL-1500 | 1500 | 1 | <20 | 150-200 | 60-300 | 22 | 10800*1720*1900 |

| 2XL-1500 | 1500 | 2 | <20 | 200-300 | 120-450 | 2*22 | 10800*3300*1900 |

| XL-2000 | 2000 | 1 | <20 | 250-320 | 160-460 | 37 | 11000*2200*2100 |

| XL-2400 | 2400 | 1 | <20 | 320-400 | 200-620 | 45 | 12500*2700*2200 |

【How to Select The Right Sand Washing Machine】The sand washer type names may vary by application and structure. Contact our engineer for quick selection help, if you are confused about what is XS type, XL type, fine sand washer, coarse sand washer, sand screw washer, spiral sand washer, bucket sand washing plant, and which one suits for washing silica sand, river sand, beach sand, aggregate, granite, etc.

【Sand Making & Washing】JXSC VSI sand-making machine and sand washing machine have a good effect on gravel, cement, pebble, quartz, and aggregate processing plants. Customizable fixed, semi-portable, and portable sand washing systems, replace the natural sand with artificial making sand.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.