Spiral Chute

【Capacity】: 0.15-10 T/H

【Feeding Size】: 0.04-2 mm

【Application】: Iron, tin, tungsten, tantalum-niobium, gold ore, coal mine, monazite, rutile, zircon, and other metals.

Chat Online on WhatsApp

Chat Online on WhatsApp

Advantages

Spiral Chute is the best equipment for mining and mineral processing, which combines the characteristics of the spiral concentrator, shaking table, and Centrifugal concentrator. It is made of fiberglass lined with wear-resistant polyurethane and corundum cover, light moisture-proof, anti-rust.

The spiral separator has the advantages of a small occupation area, small water consumption, simple structure, no energy consumption, large capacity, easy installation, easy operation, and small investment.

We supply different types of gravity separation equipment, such as gold centrifugal concentrators, shaking tables, and wet spiral concentrators(see our Mining equipment list). Spiral classifier applied in different conditions of extraction process dense media separation. Besides, the spiral chute design is available. Email us to know the spiral classifier price.

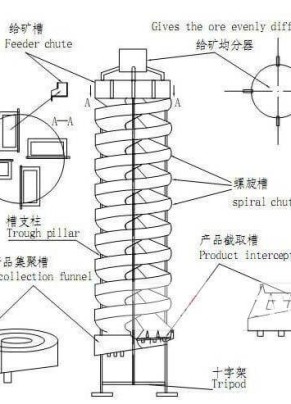

Product Structure

The Spiral separator/ spiral chute is the earliest mining machine. It has been used to classify the granularity 0.3-0.02 millimeters fine grain like iron, tin, tungsten, tantalum-niobium, gold ore, coal mine, monazite, rutile, zircon, and other metals. The non-metallic minerals which have a big enough specific gravity difference.

【Spiral chute principle】Raise the spiral chute and fix it in the proper position, sand pump send the ore to the feed inlet, adding water to adjust the concentration of the slurry. The slurry naturally swirls from high to low and generates an inertial centrifugal force in the rotating bevel flow rate. The mineral is separated from the sand by the gravity and centrifugal force of the swirl by the difference in specific gravity, grain size and shape of the ore. The concentrate flows into the concentrate bucket and is connected by the pipeline. The tail sand flows into the tailing sand bucket and is connected to the sand pool by the pipeline, and then drained by the sand pump to complete the whole process of the beneficiation.

Technical Parameters

| Model | 5LL-2000 | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 | |

| Outside Dia (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | |

| Pitch (mm) | 1200 | 900,675 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 | |

| Pitch Dia Ratio | 0.6 | 0.48, 0.36 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 | |

| Lateral Slope | 9° | 9° | 9° | 9° | 9° | 9° | |

| Number of Installed Spiral Heads | 2 | 2-4 | 2-4 | 2-4 | 2 | 2 | |

| Feeding Size (mm) | 2-0.04 | 2-0.04 | 2-0.04 | 2-0.04 | 2-0.04 | 2-0.04 | |

| Feeding Density(%) | 30-55 | 30-55 | 25-55 | 25-55 | 25-55 | 25-55 | |

| Capacity (T/H) | 7-10 | 3-5 | 3-4 | 2-3 | 0.8-1.2 | 0.15-0.2 | |

| Size | Length (mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 |

| Width (mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 | |

| Height (mm) | 5600 | 5300 | 5230 | 4000 | 2600 | 1500 | |

| Weight (Kg) | 1200 | 800 | 600 | 400 | 150 | 50 | |

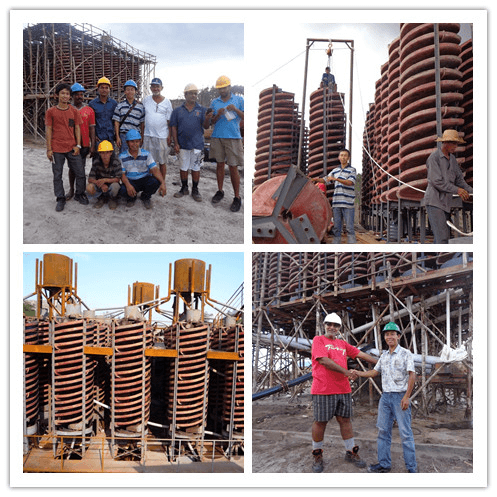

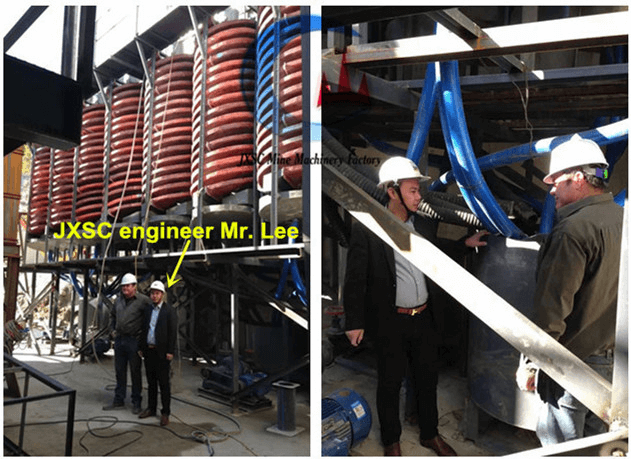

Related Cases:

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.