XFD-12 Mechanical Cell Flotation

【Impeller Speed】 0-2800 r/min

【Feeding size】 0.2 mm

【Motor Power】 250 W

【Application】Geology, metallurgy, construction, chemistry, laboratories, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

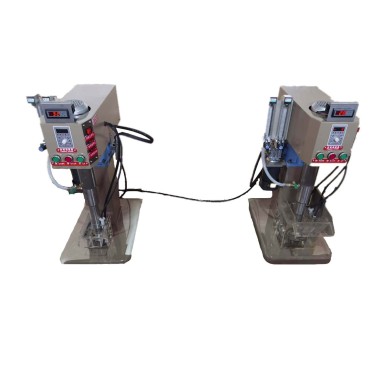

XFD-12 Mechanical Cell Flotation is employed for agitation, separation, scrubbing, and cleaning of samples in labs of geological, metallurgical, building material, chemical, coal, beneficiation plant of mine, institutions of higher learning, and research institutions.

XFD-12 laboratory multi-cell flotation machine is suitable for the flotation of non-ferrous, black, non-metallic, and coal with a particle size below -35 mesh. It can be used for flotation tests of 125-3000 grams of flotation samples. And it is produced by the only manufacturer designated by the former ministry of geology and mineral resources in compliance with Industrial standards. The XFD-12 lab flotation machine has a suspended type mechanism and include a totally enclosed anti-friction spindle bearing, stainless steel shaft, stainless steel standpipe with air control valve, three changeable stainless diffuser type hoods, and three removable stainless open type impellers of different size for use in various size stainless steel or acrylic tank.XFD-12 lab flotation machine is supplied with six flotation tank sizes, enabling it to do rougher, cleaning and scavenging tests.

【Feature】

- Adjustable impeller speed through VFD;

- Adjustable aeration control;

- Tanks are removable and easily cleaned;

- The stainless steel shaft, impeller, and diffuser are corrosion and abrasion resistant.

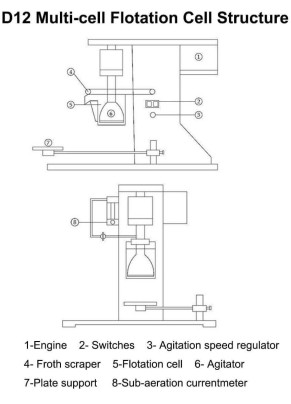

Product Structure

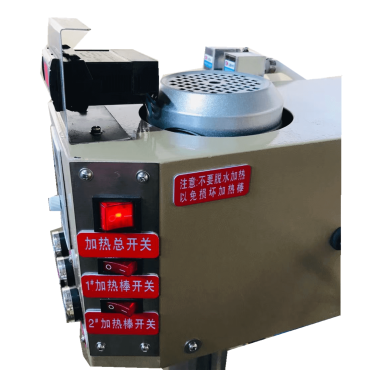

【Structure】

D12 Lab Flotation Machine mainly consists of the following parts: lifting mechanism, machine body, stator & impeller part, inverter & control system.

All the parts are connected to the vertical column. The motor drives the main shaft to rotate in a clockwise direction. The inverter controls the rotation speed of the impeller.

【Working Principle】

Before the operation, we should check if the main spindle turns clockwise normally. If not, then change the phase sequence of the power source to let the motor turns clockwise before operation. Mix mineral samples with water and then pour them into the cell. Turn on the start button of the motor to make the main spindle for rotation. The impeller will rotate in the cell. Then open the valve for air inflation and add a chemical agent to help form foams. Turn on the switch of the scraper motor for rotation of the scraper to scrape foams out of the cell. There is a box on the working table to collect foams. Minerals needed can be concentrated after processing the foams.

Technical Parameters

| Item | Ⅰ | Ⅱ | Ⅲ | |

| Impeller Diameter(mm) | Φ54 | Φ73 | Φ95 | |

| Cell Volume(L) | 0.5,0.75 | 1,2 | 4,8 | |

| Circulation Cylinder(mm) | Φ78×64 | Φ60×30 | Φ100×102 | |

| Φ78×42 | Φ60×16 | Φ100×50 | ||

| Impeller Speed(r/m) | 0-2750 | |||

| Motor | Model | JW6364 | ||

| Power(W) | 250 | |||

| Speed(r/m) | 2000 | |||

| Dimensions(mm) | 560×460×860 | |||

| Weight(Kg) | 80 | |||

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.