Description of Jig Concentrators

The sawtooth wave jig concentrator is an effective and energy-saving specific gravity separator that has found a wide application in recovery for various kinds of minerals. Unlike the traditional jigging machine, The STW jig concentrators produce speedy upward water flow and slow downward flow, so the bed layer is elevated integrally and settled fully with a long effective loose time. As a result, the STW jig machine has extremely good performance for the recovery of fine fraction particles.

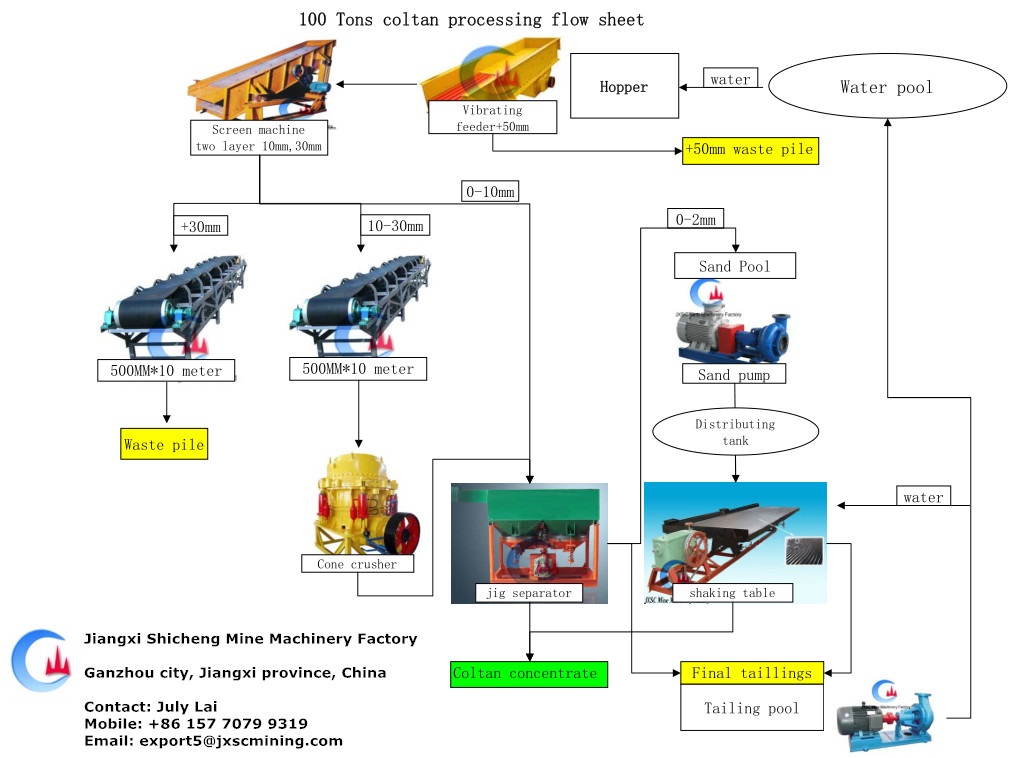

JXSC jig machine is widely used in the beneficiation of tungsten, tin, gold, diamond, iron, titanium, iron, coltan, manganese, fluorite, chrome. It can also be used for recovery for alloy particles from manganese slag, chromites slag and stainless slag, etc.

Applications of Jig Concentrators

Jig separators can be used in the following applications:

- To recover Finished Concentrate from ores in which the mineral grains are liberated. Recovery of minerals of various kinds that occur in Placer / Alluvial deposits, or decomposed rocks.

- Recovery of minerals from primary/ hard rock ore, which can be liberated by crushing/ grinding process, i.e. (Diamonds, Color Gemstones, Barite, fluorite, Gold & other precious metals, base metals, ferrous metals, light metals, coal) and heavy minerals of all kind.

- Cobbling operation, to discard waste rock before final processing of the crude concentrate.

Jig Concentrators Advantages

- Compact structure and small occupation area

- Energy saving and continuous working

- High recovery, high unit throughput and low water consumption

- Simple installation and Minimal maintenance requirements

- Stroke and frequency of stroke can be easily adjusted

| Model | Area jig | Stroke | Stroke | Feed size | Hutch water | Pressute water | Capacity | Power | Overrall dimensions | Weight |

| m2 | mm | r/min | mm | mm | kg/cm2 | mpa | t/h | mm | t | |

| JT0.57-1 | 0.57 | 8.5-12 (M12)

10-17 (M17) | 60-160 | 6 | 1-2 | ≥ 0.3 | 1-2.5 | 1.5 | 1560× 820

× 1550 | 0.612 |

| JT1-1 | 1.04 | | | 10 | 2-3 | | 4-10 | 2.2 | 1322× 1190

× 1915 | 0.9 |

| JT2-2 | 2.28 | 8.5-12 (M12)

10-17 (M17) | 60-160 | 10 | 2-4 | ≥ 0.3 | 8-15 | 3 | 3225× 1550

× 2150 | 1.637 |

| JT3-1 | 3.3 | 10-47 | 80-110 | 20 | 3-6 | ≥ 0.1 | 10-15 | 5.5 | 2662× 2000

× 3030 | 3.26 |

| JT4-2 | 4 | 7-30 | 50-125 | 10 | 4-8 | ≥ 0.1 | 8-16 | 7.5 | 4240× 1990

× 5750 | 4.6 |

| JT4-2A | 4 | 7-30 | 50-125 | 10 | 4-8 | ≥ 0.1 | 8-16 | 4 | 4240× 1990

× 2750 | 4.6 |

| JT5-2 | 4.86 | 15-25 | 80-120 | 10 | 4-10 | ≥ 0.1 | 10-20 | 7.5 | | |

Our factory JXSC has an experienced engineering team, which can do jig concentrators design, mining process flow sheet, recommend suitable machine models, as well as provide professional commissioning, training and complete after-sales services for our clients.