Gold Concentrator description

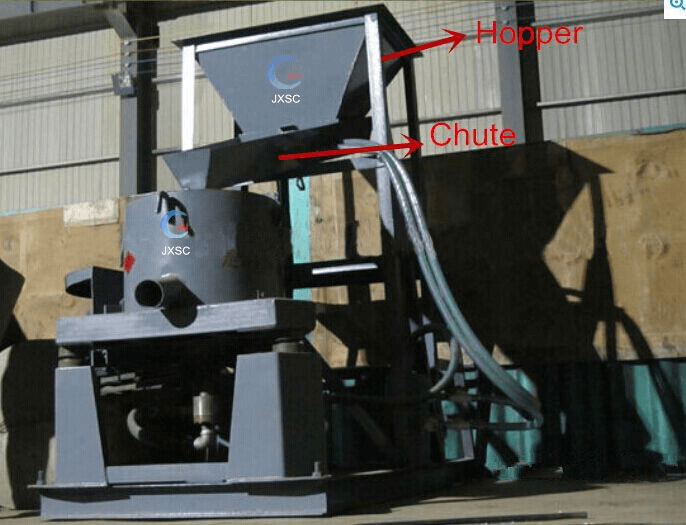

Gold Concentrator is a kind centrifugal concentration equipment. It can be used not only for alluvial / placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation. It is also used to recover gold from the old tailings.

gold concentrator for sale

Five models are available. The application shows that the recovery rate of the Fine Grain Gold Centrifugal Concentrator can be as high as 90%, especially for the case in recovering the natural gold in lode ore with 65% of the ore having a milling size of —0. 074mm, the recovery for natural gold is expected up to 98%. For those natural gold of 0.004mm in particle size, the recovery is 97%. The cleaning upcycle is 1~4 hours, and the upgrade ratio is up to 1,000 times. The equipment is patented in China.

Fine Grain Gold Recovery

The STLB Gold Centrifugal Concentrator is specifically designed for recovery of fine-grain gold, free gold, metallic gold, platinum or silver from hard rock circuits and is also an ideal technology for alluvial gold including secondary recovery from sand and gravel operations. The STLB Gold Concentrator subjects the material being processed to a centrifugal field of up to 60G’s which allows recovery of finer native metals than with conventional gravity concentration equipment. Periodically, the high-grade concentrate is removed from the concentrate cone during the rinse cycle. The rinse cycle time is typically less than 20 minutes per cycle. Optimum operating cycles will range from 1hr to 4hrs.

Advantages of Gold Centrifugal Concentrator

1.High concentrating ratio and high recovery

2. Total process automation, steady recovery performance

3. Low energy consumptions

4. Environmentally friendly(requires no chemical additives or reagents)

5. Low water and electricity requirements

6. Low production costs, durable wear parts, minimal maintenances requirements

7. Compact design requiring less space, easy merged into the existing mining processing

8. Quick payback on investment, typically less than half-year

9. Rugged design and a high degree of quality manufacturing ensure that every Concentrator will provide many years of reliable, trouble-free operation in even the most severe operating environments.

Working principle

Feeding material is screened at approximately 2-4 mm depending on the application, introduced as slurry through the central vertical feed pipe, and accelerated by the rotor. Rapid stratification according to specific gravity occurs as the material is driven up the grid concentrate cone wall under the influence of an immense gravity field. Fluidization water is injected through the rotor wall to create a dilated or fluidized bed. The high specific gravity gold or other target particles become embedded in this zone and are retained here until the machine is stopped and the concentrate is rinsed down through the concentrate discharge ports. A centrally located rinse manifold directs jets of water to thoroughly rinse concentrate from the retention zone after each operating cycle.

LATEST PRODUCTS

Plate Magnetic Separator

【Capacity】8-35 t/h 【Power】1.5-3 kW 【Applic…

Slurry Magnetic Separator

【Capacity】10-100 m3/h 【Feeding Material Densi…

Vertical Ring High Gradient Magnetic Separator

【Capacity】0.01-150 TPH【Feeding Size】0-1.2…