Iron ore distribution in the world

The total iron ore resources in the world are calculated to be 1964 million tons according to the iron content, including 930 tons of industrial reserves.

Northern Hemisphere: total resources 123.7 billion tons, industrial reserves 60 billion tons, accounting for 63% of the world’s total reserves and 64.5% of industrial reserves.

Southern Hemisphere: total resources 72.56 billion tons, industrial reserves 33 billion tons, accounting for 37% of the world’s total reserves and 35.5% of industrial reserves.

Europe: the most abundant iron ore resources, the total resources of 622 billion tons, industrial reserves of 350 million tons.

South America: total iron ore resources total 462.4 billion tons, industrial reserves of 188.7 million tons.

North America: the total amount of resources is 444.4 billion tons, and the industrial reserves are 149 billion tons.

Oceania: the total amount of resources is 191 billion tons, and the industrial reserves are 109 billion tons.

Asia: total resources of 171 billion tons, industrial reserves of 102 billion tons, the last second, rather poor.

Africa: the most scarce iron ore resources: 73 billion tons of resources and 33 billion tons of industrial reserves.

Applications of Iron ore

Iron ore is used as a catalyst for ammonia synthesis (pure magnetite), natural mineral pigments (hematite, specularite, limonite ), feed additives (magnetite, hematite, limonite) and precious medicinal stone (magnetite), but the amount is very small. Iron and steel products are widely used in various sectors of the national economy and all aspects of people’s lives. They are essential basic materials for social production and public life. Since the invention of converter steelmaking in the mid-19th century, steel has been the most important structural material, occupying a very important position in the national economy, is an important pillar industry of social development, is the most important and most widely used metal material in modern industry.

Iron ore type existing in nature :

There are many kinds of iron ore, about 300 kinds of iron ore and iron-bearing minerals have been found, of which 170 kinds are common. However, under the current technological conditions, magnetite, hematite, magnet hematite, ilmenite, limonite and siderite are of industrial value.

Iron ore Metallogenic regularity

Sedimentary metamorphic iron deposit

-Late magmatic iron deposit

-Hydrothermal iron deposit

-Related to volcanic intrusive activities

-Sedimentary iron deposit

-Weathered leaching iron deposit

-Other important iron deposits

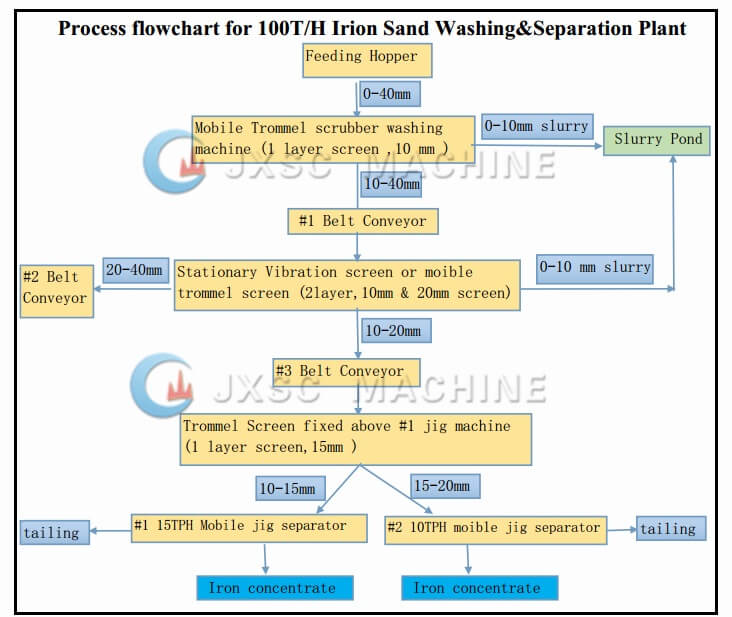

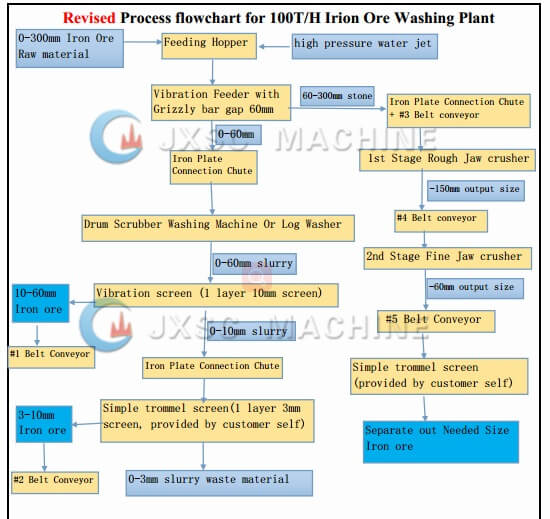

Beneficiation flowsheet of iron ore

The ore dressing technology of iron ore mainly has feeding, crushing, washing, sieving and magnetic separation process, the iron ore processing equipment are including vibration feeder, trommel scrubber washing machine or log washer or trommel screen, jaw crusher, hammer crusher, double roller crusher, cone crusher, jig separator, magnetic separator to further improve the grade of iron ore concentrate.

The Beneficiation of iron ore processing equipment is closely related to the physical and chemical properties of iron ore. Because iron ore is strongly magnetic, with the continuous improvement of magnetic separation technology, the technology of purifying iron ore with magnetic separation has been very mature. Moreover, because the magnetic separation process has no pollution to the environment, the iron ore magnetic separation technology has been popularized and applied in the major mineral processing plants.