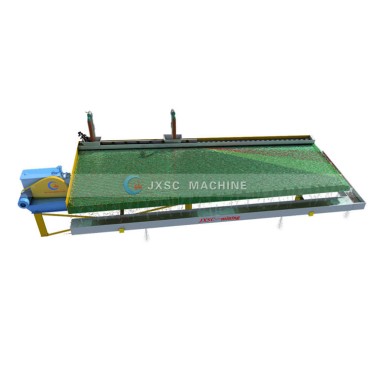

Gold Shaking Tables

【Capacity】0-2 T/H

【Feeding Density】10%-30%

【Feeding Size】0-2 mm

【Application】Gold shaker table is a gravity separator that separates gold, tin, tungsten, lead, manganese, tantalum, chrome, and other precious and nonferrous metals.

【Service】Shake table design, mineral separation test, process flow design, on-site installation.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【Gold shaking tables】 also known as gold shakers, or gold separation tables, is a fine gold recovery equipment common in the gold shaker wash plant, alluvial gold mining plant to separate concentrates, medium concentrates, and tailings according to material density, and grain size.

Gold mining shaker table can not only be used as an independent beneficiation machine, but it often works with jig machines, centrifugal concentrators, sluice boxes, flotation equipment, magnetic drum separators, spiral classifiers, and other ore dressing equipment.

【Types of gold shaking tables】

- Seated table and suspended table

- Single-layer shaker and multi-layer shaker

- Coarse particle (2~0.5mm), fine gold (0.5~0.2mm)

- RP4 shaker table, 6-s shaker

- Industrial shaker table, mini gold shaker table, lab shaker table, portable shaker table

【Table surface materials】Glass-reinforced plastics (glass fiber reinforced polyester resin) and aluminum alloy (laboratory use).

【Gold shaker table for sale】1.High efficiency, separates the gold concentrate and tailings simultaneously. 2. Easy to install, operation, and maintenance 3. Adjustable stroke length and speed 4. Low investment, long service life 5. Flexible and portable.

Product Structure

【Main parts】Head, electric motor, slope regulator, ore tank, water tank, compound strip, and lubrication system.

【Shaking table working principle】Shaking table mineral separation is an inclined table, the combined action of the symmetrical reciprocating motion of a mechanical slab and the flow of water on a thin inclined plane, causes loose layering and zoning of ore particles on the table surface, thereby causing the mineral separation process to be carried out according to different densities.

【Gold shaker table manufacturer】JXSC supply different types of shaking table concentrator globally, popular in Australia, South Africa, Ghana, Congo placer gold processing plant. JXSC gold shaking tables are a new generation gold concentrating table, with a good effect on fine gold recovery, welcome to visit us do shaking table mineral processing test. Competitive price, good quality equal to Gemini table, MSI mining equipment, Wilfley table. Contact us to get the latest shaking table price. The gold shaker table is a fairly small scale gold mining equipment compared to the ball mill, trommel scrubber, etc.

Technical Parameters

| Deck Type | Unit | Course Sand | Fine Sand | Slime Deck | Three Different Kinds of Decks Are Available | |||

| Beneficiation Area | m2 | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

| Deck Size | Length | mm | 4450 | 4450 | 4450 | 3000 | 2100 | 1100 |

| Transmission End Width | mm | 1855 | 1855 | 1855 | 1320 | 1050 | 500 | |

| Concentrate End Width | mm | 1546 | 1546 | 1546 | 1100 | 850 | 430 | |

| Maximum Feeding Size | mm | 2 | 0.5 | 0.15 | 0.1-2 | 0.074-2 | 0.074-2 | |

| Process Capacity | T/H | 1.5-2 | 0.8-1.5 | 0.5-0.8 | 0.4-1.5 | 0.3-0.8 | 0.05-0.2 | |

| Feeding Density | % | 25-30 | 20-25 | 15-25 | 10-30 | |||

| Stroke | mm | 16-22 | 11-16 | 8-16 | 6-30 | 12-28 | 9-17 | |

| Frequency | f | 45-48 | 18-53 | 50-57 | 210-320 | 250-450 | 280-460 | |

| Water Added | T/D, T/H | 80-150 T/D | 30-60 T/D | 10-17 T/D | 0.3-1.5 T/H | 0.2-1 T/H | 0.1-0.5 T/H | |

| Transverse Slope of Deck | ° | 2° 30-4° 30 | 1° 30-3° 30 | 1° -2° | 0 -10° | 0 -8° | 0 -10° | |

| Longitudinal Slope of Deck | ° | 1.4 | 1.4 | 0.92 | —— | —— | —— | |

| Cross-section Shape of Deck | Rectangular | Sawtooth | Triangle | Available rectangular, sawtooth, triangle | ||||

| Motor Power | KW | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.