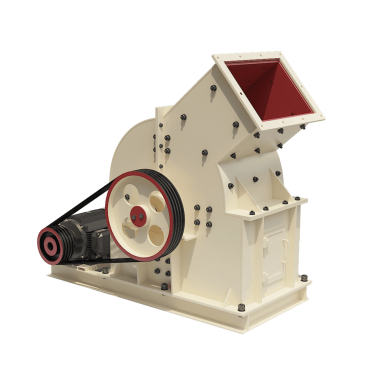

Hammer Crusher

【Capacity】1-110 TPH

【Feeding Size】<350 mm

【Application】Hammer crusher can crush medium hardness and brittle materials, such as limestone, slag, coke, coal, etc. Our hammer crushers are widely used in mining, cement, coal, metallurgy, building materials, highways, combustion, and other industries.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【What is a Hammer Mill】A hammer mill is a rock crusher used in various industries to reduce the material size, such as limestone, coal, slags, gypsum, and glass. It uses a high-speed rotary hammer to impact the ore, and the finished product size is adjustable by controlling the grate openings, rotor speed, hammer capacity, etc. A hammer mill, like a hammer crusher, or hammer breaker, can crush the 600-1800mm materials to below 25 or 25 mm. Sometimes, the application fields name the hammer mill crusher, such as coal crusher, coke crusher, limestone hammer crusher, brick crusher, cement hammer crusher, etc.

【Our Hammer Crusher Types】Single rotor and double rotor hammer crusher; directional and reversible hammer crusher; vertical shaft, ring hammer crusher, swing hammer crusher; fixed and mobile hammer crusher.

【Hammers Material】Chromium alloy (containing 20% – 27% chromium)

【Our Price】Hammer crusher price is varied by the capacity and base material. JXSC tailor-made the best configuration for different working requirements, longer service time, and less maintenance. Contact us to get the best stone hammer crusher machine price.

【Advantages of Hammer Crusher Machine】Easy adjustment of product size; high grinding capability; easy maintenance, a quick exchange of worn parts; stable operation.

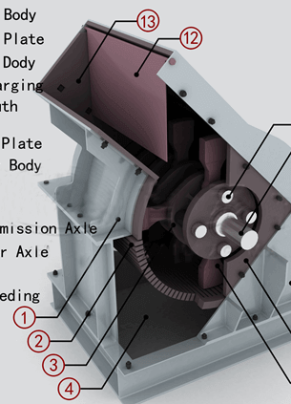

Product Structure

【Hammer Crusher Parts】Crushing chamber, rotor shaft, frame, impact hammer, grate bars, motor, flywheel, grate, pallets and lining, dust seal, overload protection device.

【Hammer Crusher Working principle】Material are fed into the hammer crusher, that is subject to rotation, high-speed impact and collision are broken. Qualified crushed ore is discharged through the grate, the larger size materials continue to be crushed and shattered until they reached the required size.

【Hammer Crusher Manufacturer】JXSC manufactures various industrial hammer mills, hammer crushers and laboratory use small hammer mills to accomplish your size reduction needs. Our rugged hammer mills employ a rain of continual, high-speed hammer blows to impact crush, grind or shred of a diverse range of materials. Other rock crusher machines like roll crusher, impact crusher, jaw crusher, cone crusher, etc.【Common Faults Solutions】

【Hammer crusher in cement plant】Impact hammer crusher (cement crusher) combines the advantages of ring hammer crusher, impact crusher, optimizes the grinding chamber, obtains a better fine crushing effect.

【Coal crusher hammer】Varied in different capacity requirements, the coal crusher hammer type generally have small capacity hammer crusher (5-55m³/h) and the heavy hammer crusher (100-3200t/h).

Technical Parameters

| Model | Feeding Size (mm) | Discharge Particle Size(mm) | Capacity (t/h) | Power (kw) |

| PCS300*200 | <60 | <10 | 1-2 | 7.5 |

| PCS400*300 | <80 | <10 | 1-3 | 7.5 |

| PC400×300 | <100 | <15 | 3-10 | 11 |

| PC600×400 | <150 | <15 | 10-20 | 22 |

| PC800×600 | <200 | <25 | 20-50 | 55 |

| PC1000*800 | <350 | <35 | 50-70 | 75-90 |

| PC1000×1000 | <350 | <35 | 70-90 | 90-110 |

| PC1200*1200 | <350 | <35 | 80-110 | 132-160 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.