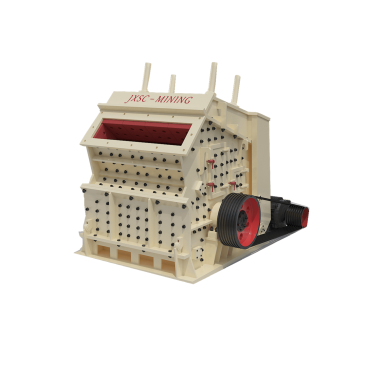

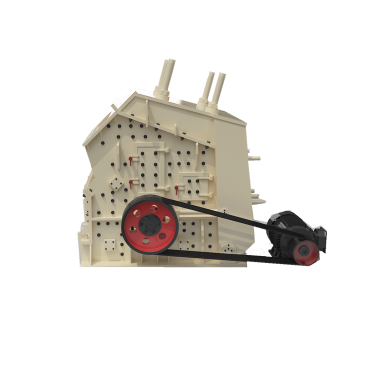

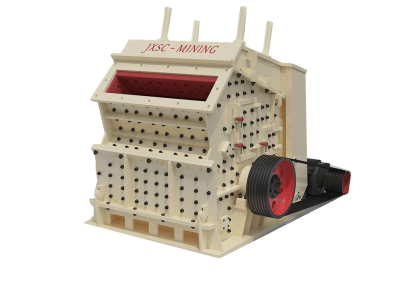

Impact Crusher

【Capacity】30-500 TPH

【Feeding Size】<700mm

【Materials】A variety of medium hardness ores, such as limestone, feldspar, calcite, talc, barite, rare earth, clay, kaolin, dolomite, kaolin, gypsum, graphite, etc.

【Applications】Metallurgy, mining, cement, ceramic, transportation, energy, construction, and chemical industry.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【What is Impact Crusher】Impact crusher (impact break) is an ideal crushing machine for medium hardness materials. It can produce a more uniform particle shape (cubical) final product than the hammer crusher. Impact crushers are widely used in the aggregate industry (cement, asphalt, sand & gravel), owing to high reduction ratios and precisely shaped, cubical end products. Impact crushers can be set in any stage of the crushing circuit from primary crushing to the last step.

【Types of Impact Crusher】Common types have horizontal shaft impact crushers (HSI) and vertical shaft impact crushers (VSI). Besides, designed stationary and mobile impact crushers (track, wheel) for different applications.

【Impact Crusher Manufacturer】Compared with well-known impact crusher manufacturers like Sandvik, JXSC has unique advantages. Lower price, complete spare parts, installation engineer & instruction manual, crushing plant design. Contact us to quickly get the impact crusher specifications and price.

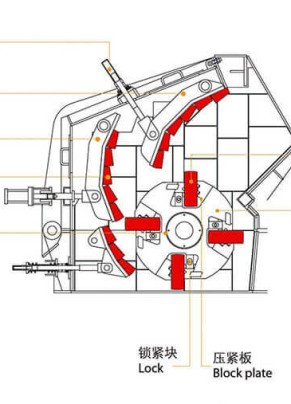

Product Structure

【Impact Crusher Parts】Hopper body, cascade cylinders, feed tubes, crushing chamber, crusher base; often replaced wear parts are worn plates, blow bars, breaker plates, etc.

【Impact Crusher Working Principle】Impact crusher is a machine that breaks materials using the impact of energy. The rotor rotates of our impact crusher with a high speed driven by a motor. When the materials get into the hammer effect area, they are impacting to break with the hammer on the rotor and then threw to the impacting position to take another crushing. After that, they spring back to the hammer impacting area from the impact wrist plate to take crushing again. This procedure repeats itself. The materials get into 1, 2, 3 impact cavities from big to small to take repeated crushing. When the material is crushed to the required size, it's discharged from the outlet. The material's discharging size and shape can be changed by adjusting the gap between the impact frame and rotator.

【What Is The Difference Between Jaw Crusher and Impact Crusher】Jaw Crusher VS Impact Crusher

Technical Parameters

| Model | Rotor Spec (mm) | Feed Opening Size (mm) | Max Feed Edge(mm) | Capacity (t/h) | Motor Power(kW) | Weight(t) | Overall Dimension (L*W*H)mm |

| PF1007 | 1000*700 | 400*730 | 300 | 30-50 | 37-55 | 9.5 | 2400*1558*2660 |

| PF1010 | 1000*1050 | 400*1080 | 350 | 50-80 | 55-75 | 12.2 | 2400*2250*2620 |

| PF1210 | 1250*1050 | 400*1080 | 350 | 70-120 | 110-132 | 14.9 | 2690*2338*2890 |

| PF1214 | 1250*1400 | 400*1430 | 350 | 130-180 | 132-160 | 18.6 | 2690*2688*2890 |

| PF1310 | 1300*1050 | 490*1170 | 400 | 80-140 | 110-160 | 16.2 | 2780*2478*2855 |

| PF1315 | 1320*1500 | 860*1520 | 500 | 160-250 | 180-260 | 19.3 | 3096*3273*2667 |

| PF-1320 | 1320*2000 | 860*2030 | 500 | 160-350 | 300-375 | 28 | 3096×3560×3185 |

| PF-1520 | 1500*2000 | 1315*2040 | 700 | 300-500 | 400-450 | 42.8 | 3890×3560×3220 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.