JXSC has provided a successful 8TPH Kaolin Process Plant in Pakistan. We offered a detailed layout design with base construction drawings and provided a complete plant machine set.

8TPH Kaolin Process Plant in Pakistan

Published Date:05 September 2023Intrdocution of 8TPH Kaolin Process Plant

1. Raw Material: Kaolin

2. Required Capacity: 0-8 T/H

3. Input Size: 0-200 mm

4. Mine Type: Loose placer with stones

5. Customer requirements: Kaolin concentrate concentration and filtration without iron removal

The raw ore is loose, including large and small stones and sand. It needs to be screened to remove waste rocks and washed. The customer specifies that a washing machine should be used to wash, select kaolin, and press and filter into a filter cake. There is no need to recycle tailings water. Kaolin products are used in manufacturing factories such as bathroom tableware and ceramics. There is no requirement for iron content, and no iron removal is required. Due to the small processing volume, the process design should be as simple and practical as possible.

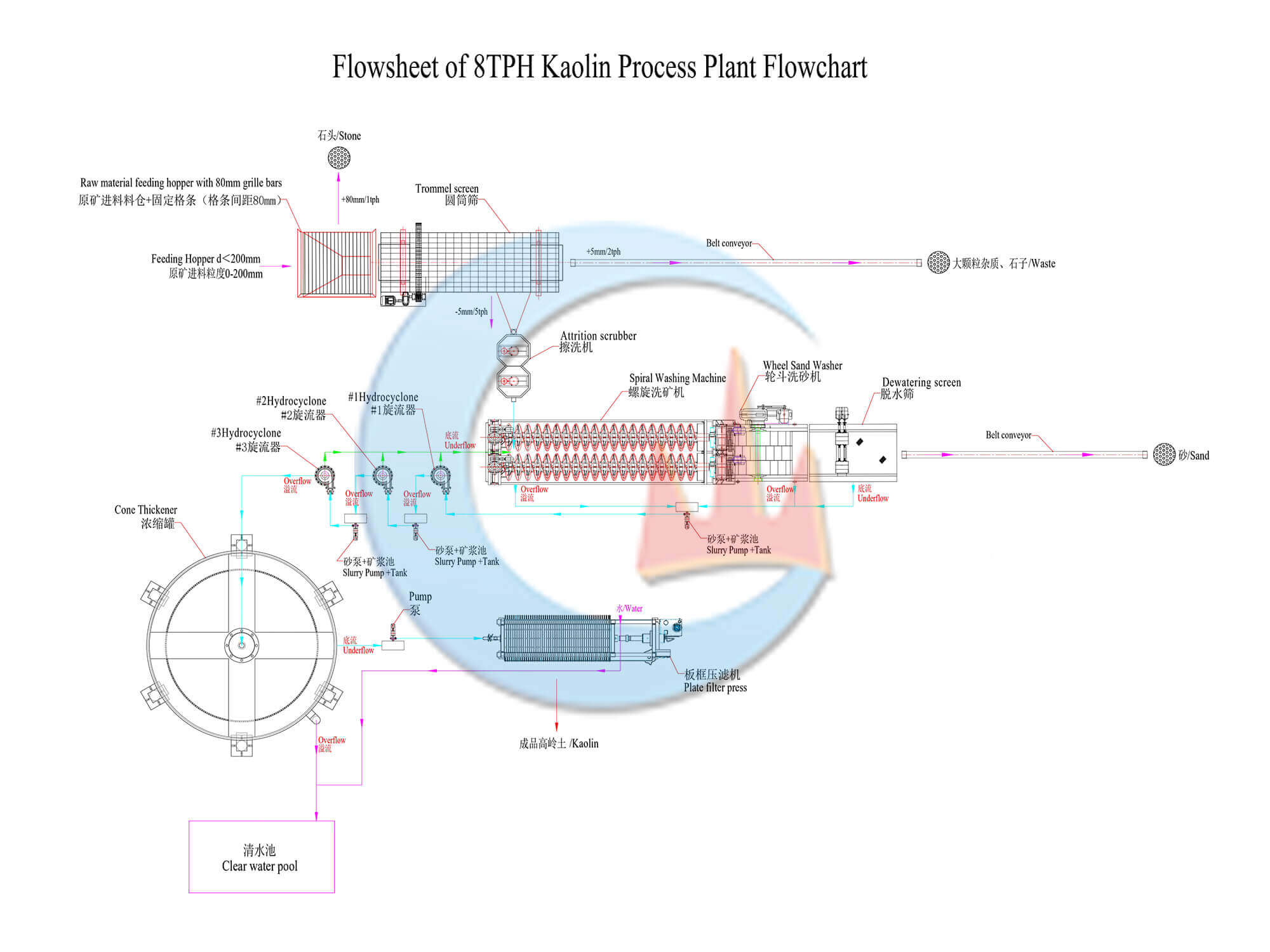

8TPH Kaolin Process Plant Flowchart

This setup is a kaolin processing plant. It is configured with a trommel screen, attrition scrubber, hydrocyclone, wheel sand washer, spiral washing machine, dewatering screen, cone thickener, plate filter press, slurry pumps, and belt conveyor.

Flowchat Description

- Use an excavator or loader to pour the raw materials into the raw material feeding hopper. The grille bars screen out the stones, and those smaller than 80mm are sent to the trommel screen.

- The material screened by the trommel screen, +5mm is waste; below 5mm materials are sent to the attrition scrubber for washing.

- Send the washed material from the attrition scrubber to the spiral washing machine. Send the washed material from the spiral washing machine to the wheel sand washer to wash. Then dewater with the dewatering screen. The overflow of the spiral washer and wheel sand washer and the underflow of the dewatering screen is collected in a slurry tank.

- Use a slurry pump to deliver the slurry to the first hydrocyclone. The overflow of the first hydrocyclone will be sent to the second hydrocyclone, and the overflow of the second hydrocyclone will be sent to the third hydrocyclone.

- Finally, the overflow of the third hydrocyclone is the kaolin slurry product, which will be collected in the slurry tanks and sent to the cone thickener for precipitation. The underflow is a higher concentration of kaolin and will be sent to the plate filter press for filtering and getting a relatively dry kaolin cake.

JXSC is a professional mining equipment manufacturer & mining ore solution expert, it has many successful cases such as gold plants, diamond solutions, etc., If you need such a service please contact us.

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.