VSI Sand Making Machine

【Feed Size】 ≤ 50mm

【Capacity】20-180 m3

【Application】In the building industry, produce high-quality aggregate, sand & gravel for water conservancy, hydropower, highway, high-speed railway, bridge, airport, municipal engineering, etc. In the mining industry, prepare fine ore for further processing.

【Suitable Materials】Pebble, limestone, granite, basalt, diabase, andesite, ore tailings, debris, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

Impact sand making machine, the abbreviation of vertical shaft impact crusher, is an important piece of equipment in the mining and artificial sand-making industry to crush and shape soft or medium hardness materials.

【Advantages】

1. High output and high efficiency: The optimized design of the deep cavity rotor increases the material throughput by about 30%.

2. Long service life: The service life is increased by more than 40%, reducing daily fault repairs, saving costs, and improving efficiency;

3. Excellent sand particle type: The processed river pebble sand particle has a beautiful appearance, reasonable gradation, and adjustable fineness modulus.

4. Environmental protection is in place: The deep cavity turbine design, good exhaust system, and efficient dust removal equipment are used to reduce dust pollution; in addition, the equipment operates smoothly, reduces the body’s vibration, and reduces the noise of equipment startup and operation.

【Pebble Sand-making Production Line】

Main Equipment: Feeder, jaw crusher, impact crusher, VSI sand making machine, vibrating screen, sand washing machine, conveyor;

The jaw crusher and the second fine crushing by the impact crusher coarsely break the river pebbles. The vibrating sieve divides the finely crushed stones into small and large particles. Fine particle materials are in the sand-making machine, while the rest of the large materials back to the impact crusher are crushed again.

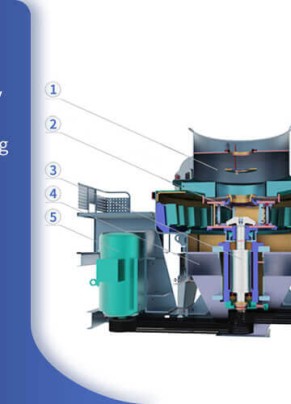

Product Structure

【VSI Sand-making Machine Structure】VSI vertical sand making machine comprises the casing, rotor, main shaft device, cooling device, motor, transmission pulley, and electric control cabinet.

【Working Principle 】The material falls vertically from the machine's upper part into the high-speed rotating impeller. Under the action of high-speed centrifugal force, it will collide with another part of the material that is diverted around the impeller in the form of an umbrella. Between the casings, the materials form eddy currents that collide and rub against each other multiple times and are crushed, discharged directly from the lower part, forming a closed circuit multiple cycles, and controlled by the screening equipment to achieve the required particle size of the finished product.

Technical Parameters

| Model | Max Feeding Size | Through Put(m3) | Capacity(m3) 【Soft Material+10%】 | Speed of Main Shaft (r/min) | Power(kW) | Dimension(mm) |

| DN-5000 | 35mm | 40-60 | 20-35 | 1700-1890 | 90 | 3800*2180*2425 |

| DN-6000 | 35mm | 60-80 | 30-40 | 1560-1720 | 160 | 4240*2200*2778 |

| DN-7000 | 40mm | 100-120 | 40-50 | 1550-1650 | 132*2 | 4700*2200*2850 |

| DN-8000 | 40mm | 160-200 | 64-80 | 1400-1720 | 160*2 | 5200*2250*3250 |

| DN-8500 | 45mm | 180-200 | 72-80 | 1400-1720 | 200*2 | 5200*2350*3250 |

| DN-9000 | 45mm | 220-250 | 80-96 | 1510-1650 | 250*2 | 5200*2450*3250 |

| DN-9500 | 45mm | 250-270 | 96-108 | 1510-1650 | 280*2 | 5200*2250*3450 |

| DN-10000 | 50mm | 270-350 | 120-180 | 1480-1600 | 315*2 | 5200*2250*3450 |

| Note: the above capacity is based on the loose specific gravity of 1.6t/m3 rock stone | ||||||

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.