Mesh Belt Dryer

【Capacity】60-300 Kg/h

【Drying Length】8-10 m

【Working Temperature】50~140

【Steam Pressure】0.2~0.8 MPa

【Power】11.4-14.7 kW

【Procession Material】Various briquettes, such as coal briquettes, mineral powder briquettes, iron powder briquettes, and fluorite powder briquettes.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【Description】 Mesh belt dryer is also called a chain plate dryer. It is a batch-type, continuously working drying equipment. The mesh belt conveyor drying machine is usually used to dry various briquettes, such as coal briquettes, mineral powder briquettes, iron powder briquettes, and fluorite powder briquettes. The stainless steel mesh belt dryer is also an ideal equipment for the dehydration of flake, strip, block, and granular materials such as traditional Chinese medicine decoction pieces, fruit slices, vegetables, food, agricultural, and sideline products, aquatic products, feed, and chemical raw materials.

【Applications】

- Food Industry: De-watering vegetables, particle feed, monosodium glutamate, shredded coconut stuffing, garlic, cushaw, turnip, yam, bamboo shoots, etc.

- Chemical Industry: Organic pigment, compound rubber, acryl fiber, medicine material, etc.

- Others: Plastic products, small wooden products, aging for the electronic component device.

【Heat Source】The main heating modes are electric, steam, and hot air.

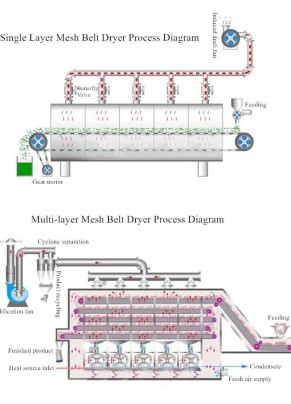

Layers】Single layer or multi-layer, customized according to demand. Length is optional too.

【Advantages】

- It can dry the briquettes continuously. The dimension is larger, and the drying capacity is bigger.

- Less wearing parts, durable service.

- The mesh belt dryer machine has multiple functions, saving time, labor, and labor. It is especially suitable for flow operation.

- Because the conveyor belt is mesh, it is also suitable for drying regular or irregular blocks and strips, such as shaped coal blocks, mineral powder balls, and aquatic products.

- The configuration of the mesh belt dryer is flexible, and it can be used together with other equipment or alone.

Product Structure

【Mesh Belt Dryer Structure】

The mesh belt dryer is composed of a head, drying section, tail, mesh belt, transmission device, feeding and distributing equipment, air inlet pipe, air outlet pipe, fan, heat source equipment, conveying equipment, etc.

The charcoal briquette drying machine distributes the materials to be treated on the conveyor belt. The conveyor belt adopts a 12-60 mesh steel mesh belt. The conveyor belt moves back and forth in the dryer through the channel composed of one or several heating units, which are driven by the transmission device. Each heating unit is equipped with an air heating and circulation system, and each channel has one or several dehumidification systems. When the conveyor belt passes through, hot air flows through the materials, Water vapor is discharged from the dehumidification hole, so as to achieve the purpose of uniform drying. The length of the box is composed of standard sections. In order to save the site, the drying machine can be multi-layer. The common ones are two rooms and three floors, two rooms and five floors, with a length of 6-40m and an effective width of 0.6-3.0m.

【Mesh Belt Dryer Working Principle】

The material has the nose to enter slowly through the drying for drying, net belt line speed depending on the type of material and water content. Airflow to the use of negative pressure, and porous air, to ensure the effective drying area, wind speed distribution uniformity, and improve the drying effect. In order to get the best drying effect and the appropriate output, the water content of the material, the line speed of the net belt, the air volume and the air temperature must be the appropriate, reasonable, and organic combination.

Technical Parameters

| Model | Belt Width (mm) | Feeding Section Length (m) | Drying Area(m2) | Layer Number | Interlamellar Spacing (mm) | Loading Capacity (kg/m2) | Operation Temperature (℃) | Evaporation Intensity(kg/m2•h) | Heat Source | Running Speed (m/min) | Accessories |

| MBD600 | 600 | 1 | 3.6-36 | 1-5 | 400-600 | 90-200 | Carbon Steel≤400℃ Stainless Steel≤600℃ | 5-20 | Hot air, electric, steam, etc. | 0.06-1 | Conveyor, air heater, dust collector, draft fan, etc. |

| MBD800 | 800 | 1 | 4.8-48 | ||||||||

| MBD1000 | 1000 | 1 | 6-80 | ||||||||

| MBD1200 | 1200 | 1 | 7.2-96 | ||||||||

| MBD1600 | 1600 | 1 | 12.8-105.6 | ||||||||

| MBD2000 | 2000 | 1.5 | 20-260 | ||||||||

| MBD2400 | 2400 | 1.5 | 28.8-360 | ||||||||

| MBD3000 | 3000 | 2 | 36-600 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.