Gold Flotation

The gold flotation process method is widely used for recovering gold from gold-containing copper ores, base metal ores, copper-nickel ores, platinum group ores, and many other ores where other processes are not applicable.

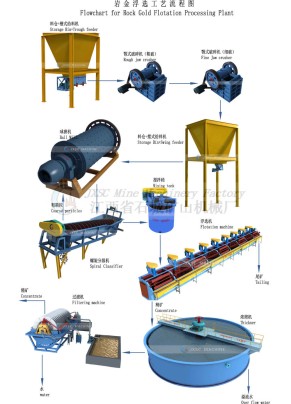

Related Equipment: Vibrating feeder, rotary crusher, fine crusher, ball mill, spiral classifier, mixing tank, flotation machine, thickener.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The Gold Flotation Process means that gold ore is generally crushed by gold mining equipment (crusher equipment, Jaw crusher), crushed by gold processing equipment (ball mill), and treated by gold panning equipment such as flotation machine, etc. Through gravity separation, flotation machine, extraction of metals from ores, and then the application of mineral reagents through chemical methods, and finally after smelting, the final product into finished gold processing.

Gold ore is a mineral aggregate with sufficient gold content and can be used industrially. Gold mines are places where gold is obtained through mining operations. According to the structural state and the content of gold in the ore, the gold deposit is a kind of industrial deposit formed by Mineralization. The gold minerals in gold deposits can be divided into three categories: Gold minerals, gold-bearing Minerals, and gold-bearing minerals. The so-called independent mineral of gold refers to gold in the form of gold and gold-bearing minerals.

Whether the gold ore is applicable to the flotation method depends on whether it has better floatability.

For simple ore just containing gold, the granularity of gold is uniform, and high floatability, a simple grinding and flotation process is always the best solution. Gravity or amalgamation operation will be set in the grinding and classification circuit if the ore contains some particle gold. Gold is usually concentrated in mineral concentrate by flotation if the gold is contained in polymetallic ore.

Product Structure

In the flotation process, the following steps are included: crushing and screening, grinding and classification, flotation, thickening, filtration, etc.

The common equipment includes jaw crusher, cone crusher, belt conveyor, vibrating screen, ball mill, spiral classifier, flotation cell (or flotation column), slurry pump, thickener, ceramic filter, etc.

Common flotation agents include: collecting agents, foaming agents, adjustment agents.

The main factors affecting flotation include grinding fineness, slurry concentration, the dosage of agents, volume of aeration, flotation time, and so on.

Technical Parameters

The parameters of each equipment are selected according to the processing capacity of the concentrator.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.