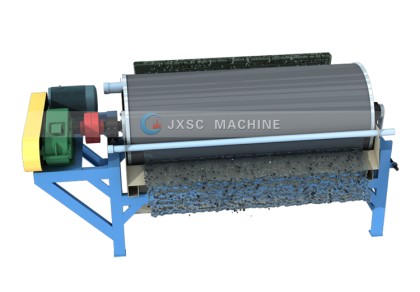

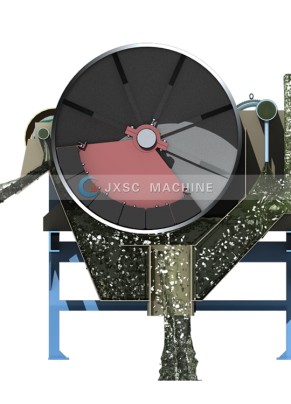

Wet Drum Magnetic Separator

【Capacity】 0.5-180 T/H

【Feeding Size】 0-3 mm

【Application】 Magnetite, pyrrhotite, roast ore and ilmenite, and other materials with particle sizes less than 3mm. Wet drum magnetic separator is also used for iron removal of materials such as coal, non-metallic minerals, and building materials.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【What’s Magnetic Separator?】

The wet drum magnetic separator is a commonly used iron ore processing equipment (iron ore magnetic separator) and manganese ore equipment (manganese ore magnetic separator) and is a mainstream strong magnetic separator ore dressing equipment.

【Application of Magnetic Separation】 Wet drum magnetic separation is suitable for wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite, and other materials with a particle size of 3mm or less. It is also used for iron removal of coal, non-metallic minerals, building materials, etc.

1. Simple structure

2. Big capacity

3. Simple operation

4. Easy maintenance

JXSC has been a professional magnetic separator manufacturer in the magnetic separation equipment business since 1985.

Types of Magnetic Separators: Dry Drum Magnetic Separator, Wet magnetic separator, Roller Electrostatic Separator, ARC type electrostatic separator, Three-disc dry magnetic separator, High-Intensity Magnetic Separator, magnetic separator laboratory.

Product Structure

【Magnetic Drum Separator Working Principle】During the processing, the non-magnetic minerals in these minerals will fall off during this continuous turning process, and those that are adsorbed on the surface of the cylinder of the magnetic separator are the concentrates left by the equipment while producing. Due to the magnetic treatment of such a cylinder, these concentrates basically reach the weakest ends of the cylindrical magnetic force as the cylinder flips, and at the same time, under the action of the water flow discharged from the unloading water. And then into the concentrate tank of the concentrate, and other minerals left after treatment are discharged to the outside of the cylinder in the north. Such a mineral with a small amount of use is tailings.

According to the needs of users, it can provide magnetic separation of many different surface strengths such as downstream, semi-reverse flow and counterflow. The magnetic separator has the advantages of simple structure, large processing capacity, convenient operation, easy maintenance.

Technical Parameters

| Model | Shell Diameter(mm) | Shell Length(mm) | Shell Rotation Speed(r/min) | Feeding Size(mm) | Processing Capacity(t/h) | Power(kW) |

| CTB4060 | 400 | 600 | 48 | 2-0 | 0.5-1 | 1.1 |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.