Tantalum Niobium Tin

Tantalum is mainly used as a high-quality capacitor, and because of its good heat conductor, it can be used as a component of various heat exchangers and heaters, and can also be used in medical equipment due to corrosion resistance. Niobium has a high melting point and is mostly used in the aviation field. Because of its corrosion resistance, it is mostly used to improve the strength and corrosion resistance of alloy materials. Tantalum niobium carbide can be used as a superhard cutting tool.

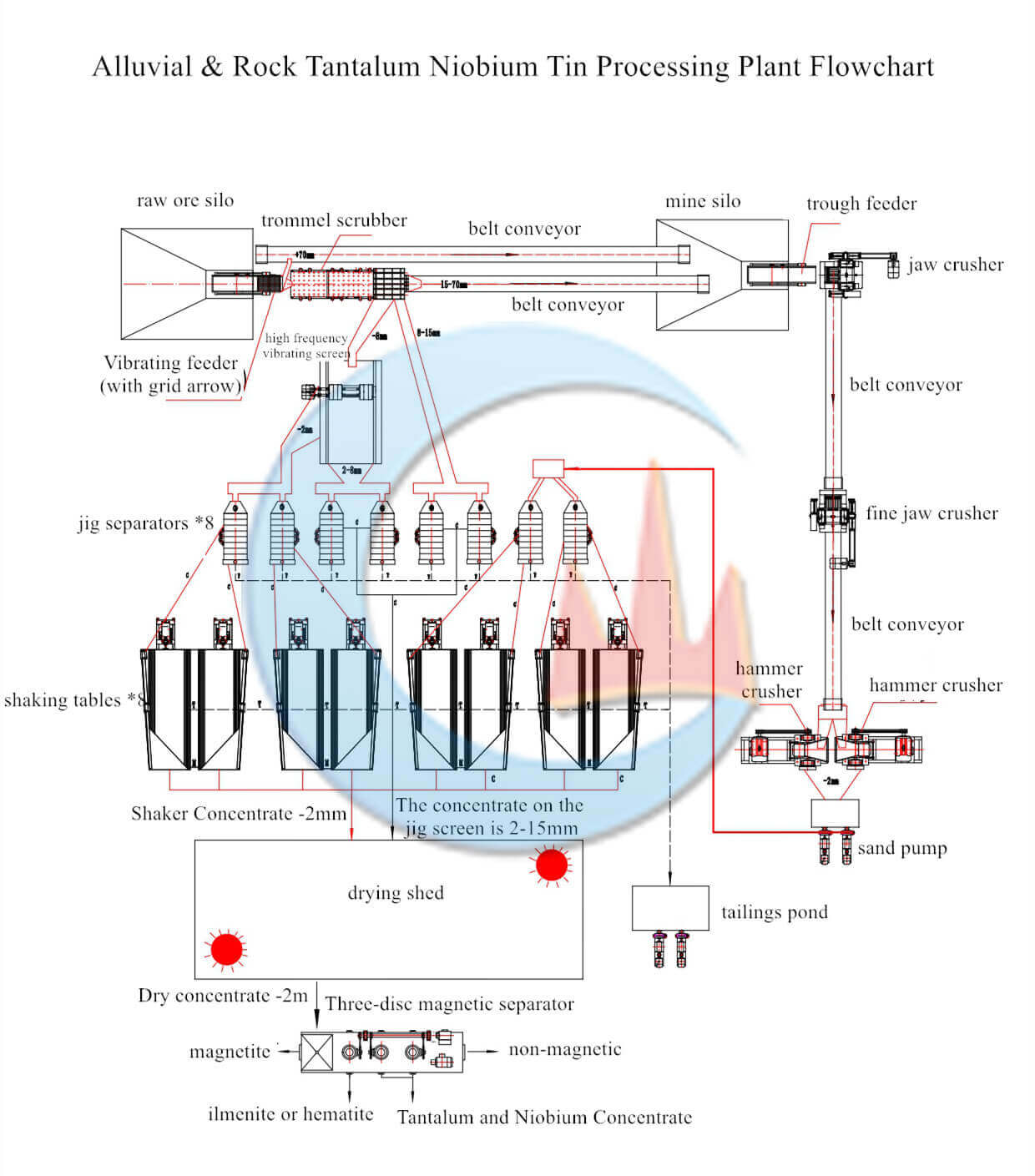

With the depletion and increasing shortage of tantalum ore, tantalum in tin slag has gradually become the main source of tantalum in the world. Coltan (short for columbite–tantalites and known industrially as tantalite) is a dull black metallic ore from which the elements niobium and tantalum are extracted. The niobium-dominant mineral in coltan is columbite and the tantalum-dominant mineral is the tantalite.