Wet Pan Mill

【Capacity】0.5-3 TPH

【Feeding Size】 <30mm

【Discharge Size】 0.074-0.6mm

【Procesible Material】 Gold, iron, molybdenum, lead, zinc, antimony, etc.

【Advantages】Pan Mill is now the best and most economical replacement for small or medium-scale milling machines, such as ball mills. It is widely used in small and medium mineral processing plants in African countries like Sudan.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【What is a Wet Pan Mill?】 A Wet Pan Mill also known as an amalgamation grinding mill, or gold grinder mill, is a versatile ore grinding pan mill for wet materials. It’s the best replacement for a medium-small capacity ball mill, owing to its excellent performance for wet crushing, small investment, and high output. It is widely used for separating gold, iron, molybdenum, lead, zinc, antimony, etc.

【Type】Single roller, double rollers (common), three-rollers.

【Advantages】Uniform grinding, fine grind small to 1mm. High capacity, output ranges up to 40 tonnes per hour. Low energy consumption, silent, safe operation. Easy to operate and maintain. Smooth, well distributed. Wearable grinding roller, longer service life.

【Wet Pan Mill Vs Ball Mill】Wet pan mill for gold selection has a lower price. JXSC wet pan mills are popular in African countries like Sudan, Egypt, and South Africa.

JXSC, a 30+ years mining machinery supplier, is our gold mining equipment/ gold panning equipment/ coal mining equipment popular in the African placer gold mining industry. JXSC has been delicate in supplying high-quality mining machinery worldwide for decades, and the China mining machine deserves your trust. Contact Us to Get The Wet Pan Mill Price!

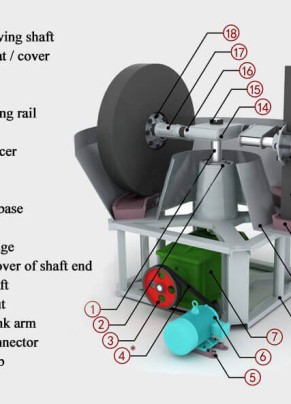

Product Structure

【Main Parts of Gold Wet Pan】Motor, stand, basin, roller, grinding base, bearing, reducer, etc.

(1) Roller Material: 6% manganese alloy steel, which can last at least 3 years.

(2) Ring Material: Optional casting steel, casting iron and manganese steel. Thickness: Standard 85mm Steel.

(3) Steel stand: A-2 standard steel frame

(4) Basin: 5mm thickness steel plate

(5) Gearbox: Specially design for wet pan mill, 1-year quality guarantee

(6) Motor: Simens or China 1st level standard Brand

【Wet Pan Working Principle】First, the motor transfers power to the decelerator, then the central drive shaft transfers to the horizontal shaft, finally the Roller moves the anticlockwise direction, the material in the wet mill is ground into fine particles. While rolling and kneading the minerals, the roller mixes the material and water thoroughly, the monomer dissociated mineral fine particles float to the upper surface and are discharged through the overflow discharge port; coarse-grained minerals settle at the bottom of the pan and continue to be ground until the fineness reaches the standard.

【Chinese Wet Pan Mill Manufacturer】Roll gold machine/wet pan mill/wet grinding mill for sale! Click to explore more stone crusher machines. If you are also interested in Magnetic Separation, flotation machine, Small scale mining equipment and so on, make a quick quota to get the wet pan mill price, please feel free to contact us.

Technical Parameters

| Model | Feeding Size(mm) | Output Size(mm) | Capacity(t/h) | Rotation Speed(r/m) | Power(kW) | Weight (t) |

| 1100 | <20 | <1 | 0.5 | 11-19 | 5.5 | 4.8 |

| 1200 | <20 | <1 | 0.5-1 | 11-19 | 7.5 | 5.2 |

| 1400 | <20 | <1 | 1-1.5 | 18-21 | 15 | 9.5 |

| 1500 | <30 | <1 | 1.5-2 | 18-22 | 22 | 11 |

| 1600 | <30 | <1 | 2-3 | 18-20 | 30/37 | 12.5 |

Don’t hesitate to contact us for more wet pan mill details and price lists.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.