Vacuum Disk Filter

【Filtering Area】10-120 ㎡

【Capacity】0.85-1.2 t/h•m2

【Procession Material】Iron concentrate ore, iron tailing, manganese ore concentrate, manganese tailing, coals, etc.

【Application】Widely used in non-ferrous metallurgy, chemical, pharmaceutical, food, environmental protection, power plants, coal treatment, sewage treatment, and other industries.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

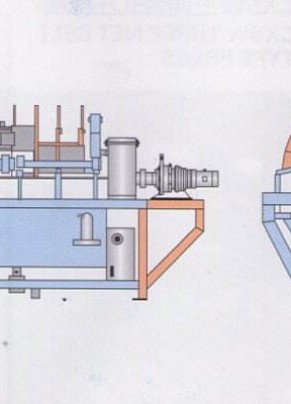

The Vacuum Disk Filter consists of a slowly revolving drum, the lower half of whose circumference is submerged in the pulp to be filtered.

Disk Filters consist of a number of parallel, individual, cloth-covered disks mounted on a hollow shaft through which suction and compressed air may be applied.

- High vacuum (degree of vacuum 0.09 ~ 0.098 MPa), low cake moisture.

- Filtrate solids content <50 ppm. It can be repeatedly used to reduce emissions.

- Compared with conventional filtration equipment energy savings of about 90%, low energy consumption, and low running costs.

- Compared with traditional ceramic filter cake was washed increases for cleaning materials.

- Using PLC, PC combined with automatic valve control, and a high degree of automation, reduces labor intensity.

- Compact, small footprint, easy installation and maintenance.

- An advanced drainage system may be suitable for use under any working conditions.

Product Structure

Technical Parameters

| Model | PGT10-2 | PGT15-3 | PGT20-4 | PGT25-5 | PGT30-6 | PGT35-7 | PGT40-8 | PGT45-9 | PGT50-10 | PGT60-12 | PGT60-5 | PGT72-6 | PGT84-7 | PGT96-8 | PGT108-9 | PGT120-10 | |

| Filtering Area (m2) | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 60 | 72 | 84 | 96 | 108 | 120 | |

| Filter Tray Qty (Pcs) | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 5 | 6 | 7 | 8 | 9 | 10 | |

| Filter Tray Dia (mm) | 2100 | 3100 | |||||||||||||||

| Power of Main Spindle Motor (KW) | 2.2 | 3 | 4 | 5.5 | 5.5 | 7.5 | 11 | ||||||||||

| Power of Stirring Motor (KW) | 3 | 4 | 5.5 | 7.5 | 7.5 | 11 | 15 | ||||||||||

| Discharge Method | Blowback | ||||||||||||||||

| Size (L*W*H) | Length(mm) | 2535 | 2925 | 3315 | 3705 | 4095 | 4485 | 4875 | 5265 | 5655 | 6435 | 4735 | 5235 | 5735 | 6235 | 6735 | 7235 |

| Width (mm) | 2480 | 4280 | |||||||||||||||

| Height (mm) | 2690 | 3740 | |||||||||||||||

| Capacity (t/h•m2) | 0.85-1.2 (t/h•m2) | ||||||||||||||||

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.