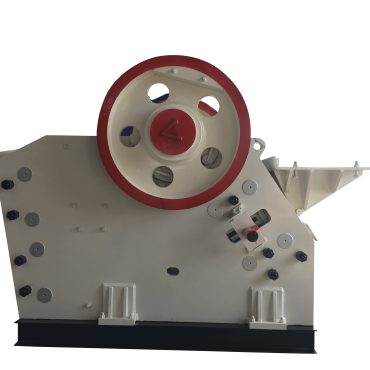

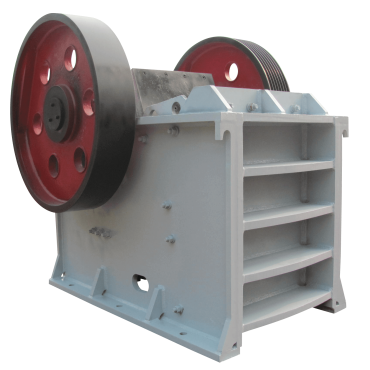

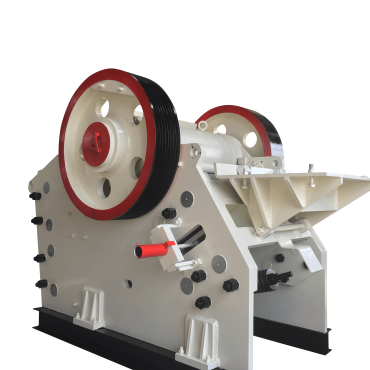

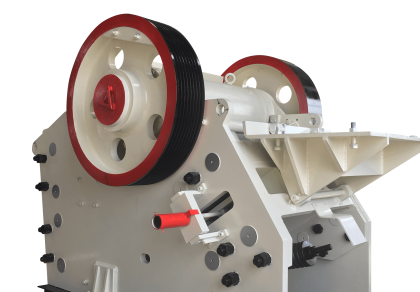

Jaw Crusher

【Capacity】 1-1120tph

【Feeding Size】 <1200mm

【Output Size】 10-360mm

【Crushing Materials】Granite, dolomite, river pebbles, quartz, calcite, and other materials.

【Application】 Jaw crushers are mainly used at the primary stage to reduce hard and brittle material size for the next crushing stages, widely applied in the mining, road aggregate, quarry, sand, and gravel industries.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【What’s a Jaw Crusher?】A jaw crusher is a compression-type crusher, usually used as a primary crusher set at the front of the ore or rock-crushing plant to reduce hard rock size. Jaw rock crushers commonly double-toggle jaw crushers, are composed of a fixed jaw and a moving jaw. The discharging stone particle size can be controlled by changing the discharge port. Owing to its high crushing capacity and hard material efficiency, jaw crushers are a good alternative to primary gyratory crushers.

【How Many Types of Jaw Crushers?】Single toggle jaw crushers and double toggle jaw crushers; industrial jaw crushers and laboratory small jaw crushers; diesel engine jaw crushers; hydraulic jaw crusher; stationary, mobile jaw crusher, track mounted jaw crusher; PEX / PE jaw crusher.

【What’s The Jaw Crusher’s Size and Capacity?】The size of a jaw crusher is determined by the rectangular or square opening (feeding port) at the top of the jaws. The sheet below shows different gaps for coarse and fine crushing applications, PE Jaw Crusher (coarse crushing), and PEX Jaw Crusher (fine crushing).

【Jaw Crusher Plant】JXSC can design a reasonable jaw crusher plant depending on your application requirements.

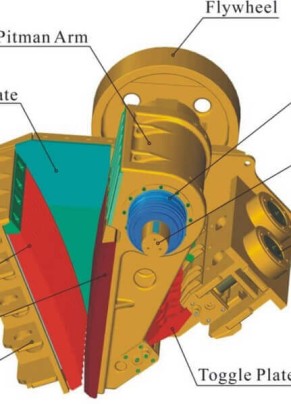

Product Structure

【Jaw Crusher Parts】Flywheel, pitman, hydraulic cylinder, toggle plate, eccentric shaft, fixed jaw, moving jaw, etc.

【Jaw Crusher Working Principle】Motor drive belt and pulley, the eccentric shaft pushes the movable jaw against the fixed jaw, generates the crushing action, compresses the material to the desired size. The crushed materials are discharged from the discharge port, the bottom gap of the crusher controls the discharge particle size.

【Jaw Crusher Manufacturer】JXSC manufactures various types of rock crushing machines that are designated with the maximum efficiency, safety, productivity for mining, aggregates, crushed stone production applications, alternative for Nordberg, Sandvik jaw crusher. JXSC jaw crusher machine for sale, contact us to get the best jaw crusher price.

【Jaw Crusher Price】Do you need a single jaw stone crusher or crushing plant? The price is determined by the crushing material, capacity. You may interest in the Jaw crusher specification and cost, how to select a jaw crusher? What is the difference between a jaw crusher and an impact crusher? What jaw crusher spare parts do we supply? Just contact us, engineer answer online.

【More May You Like】Jaw Crusher VS Impact Crusher,Jaw Crusher VS Gyratory Crusher, Single Toggle vs Double Toggle Jaw Crusher, Jaw Crusher Operation.

Technical Parameters

| Model | Feeding Size(mm) | Max Feeding Size(mm) | Discharging Range Size(mm) | Capacity (t/h) | Motor Power(kw) | Weight(t) | Overall Dimension (LxWxH)(mm) |

| PE-150*250 | 150*250 | 130 | 10-60 | 3-15 | 5.5 | 2.2 | 1000x1450x900 |

| PE-250*400 | 250*400 | 210 | 20-80 | 5-20 | 15 | 2.8 | 1450x1315x1296 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.65 | 1565x1732x1586 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 11.73 | 1890x1916x1870 |

| PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 16.13 | 2305x1840x2298 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 | 2450x2472x2840 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 | 2610x2556x2800 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 31.22 | 2660x2556x2800 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 | 2690x2556x2800 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 | 3335x3182x3025 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 | 3435x3182x3025 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 4200x3732x3843 |

| PE-1500*1800 | 1500*1800 | 1200 | 210-360 | 525-1120 | 280-335 | 132 | 5100x4700x4300 |

| PEX-150*250 | 150*250 | 125 | 10-40 | 1-3 | 5.5 | 2 | 896x745x935 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 | 1380x1658x1025 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 30 | 4.96 | 1545x1667x1330 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 | 1530x1992x1380 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37-45 | 8.52 | 1900x2192x1430 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 55-75 | 12.6 | 1750x2320x1724 |

| PEX-350*1200 | 350*1200 | 300 | 70-140 | 25-120 | 75 | 12.35 | 2162x2220x1723 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.