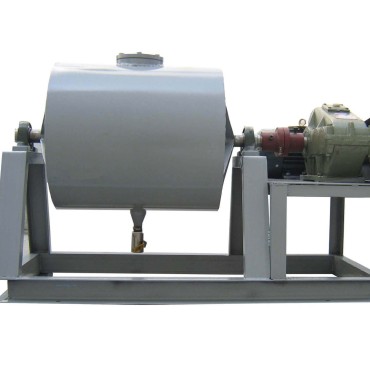

Batch Small Ball Mill

【Maximum Charge】 0.1-40 Tons/Time

【Max Feeding Size】 <25mm

【Discharge Size】0.075-0.4mm

【Motor Power】2.2-132kW

【Scope of Application】 Cement, silicate products, new building materials, refractories, chemical fertilizer, beneficiation of black and non-ferrous metals, glass ceramics, and other production industries

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

A batch ball mill is a machine to grinds the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal, and glass ceramics.

The batch mill is mainly used for the mixing and grinding materials, with uniform product fineness and saving power. The grinding time can be adjusted according to the fineness of the grinding material. The batch ball mills can be used for both dry and wet grinding.

【Batch Ball Mills & Continuous Ball Mills】

The batch ball mill is a ball milling machine that discharges the material at one time according to the nature of the material. Unlike a continuous ball mill, the batch-type ball mill grinds powder over time and adopts intermittent operation.

【Batch Small Ball Mills】

The batch small ball mill is a horizontal ball mill. Its discharge method is overflowing, also called an overflow ball mill. Because it’s small, sometimes it can be called a laboratory ball mill too.

【Characteristics of Batch Small Ball Mill】

- Less investment

- Energy-saving and electricity saving

- Novel structure

- Simple and safe operation

- Stable and reliable performance

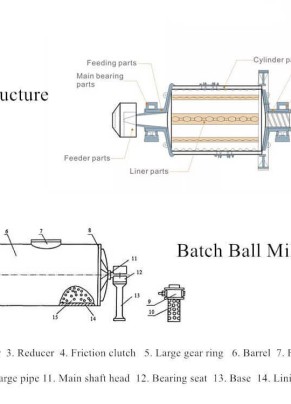

Product Structure

【Batch Ball Mill Structure】 The batch ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, pinion, motor, electric control), and other main parts. The hollow shaft is made of steel casting with a removable lining. The rotary gear is processed by casting hobbing. The cylinder is embedded with a wear-resistant lining plate, which has good wear resistance. The batch mill runs smoothly and works reliably.

【Batch Ball Mill Working Principle】The batch ball mill is of horizontal, cylindrical, and tubular structure. It comes with two cabins and is a grate ball mill. The materials are evenly fed through the charging device to the first warehouse where there are step scales boards, corrugated scale boards, and different specifications of steel balls. When the cylinder rotates, the centrifugal force produced causes the steel balls to impact and grind the materials in the ball mill. The materials are then lead to the second cabin for further milling until they turn into powders and are discharged from the outlet.

Technical Parameters

| Specification | Cylinder Speed(r/min) | Motor Power(kW) | Cylinder Volume(L) | Loading Volume(L) | Ball Volume(L) | Weight(kg) |

| 50L | 55 | 2.2 | 50 | 20 | 25 | 100 |

| 100L | 50 | 3 | 100 | 40 | 50 | 220 |

| 200L | 50 | 4 | 200 | 90 | 100 | 360 |

| 300L | 50 | 4 | 300 | 130 | 150 | 510 |

| 500L | 45 | 5.5 | 500 | 200 | 225 | 780 |

| 1000L | 40 | 11 | 1000 | 450 | 500 | 1060 |

| 1500L | 35 | 15 | 1500 | 700 | 750 | 1600 |

| 2000L | 35 | 18.5 | 2000 | 900 | 1000 | 2200 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.