5 Deck High-frequency Screen

【Motor Power】2.2 KW × 2

【Number of Sieve Box Layers】5 Layers

【Capacity】25-35 TPH

【Screen】 Polyurethane

【Maximum Screening Efficiency】 ≥ 90%

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The 5 Deck High-frequency Screen is arranged in staggered layers from top to bottom. That is multiple single-layer fine screens are integrated into one machine, each screen surface independently completes the feeding and screening operations, and the substances under and on the screen of each screen surface are collected and discharged respectively, to ensure the processing capacity and reduce the floor area at the same time. As its name suggests, the 5-deck vibrating screen has 5 screens.

Features

- High operating frequency

The operating frequency of high-frequency laminated vibrating screens is usually above thousands of times per minute (Hz), which means that its vibrations are faster and more efficient and can better separate fine particles. - High screening efficiency

Due to the effect of high-frequency vibration, the particles move quickly on the screen, thereby improving the screening efficiency. It is beneficial for handling fine granular and powdery materials. - High screening accuracy

High-frequency vibrations pass through the screen more efficiently, so higher screening accuracy is achieved, and a smaller particle size range is separated. - Multi-layer screening

Like traditional laminated vibrating screens, high-frequency laminated vibrating screens usually have multi-layer screens, allowing particles to be screened multiple times simultaneously, further improving screening efficiency and accuracy. - Wide applicability

High-frequency laminated vibrating screens can be used in various fields, including mining, metallurgy, building materials, food processing, medicine, etc., for screening, grading, impurity removal, and other applications.

Product Structure

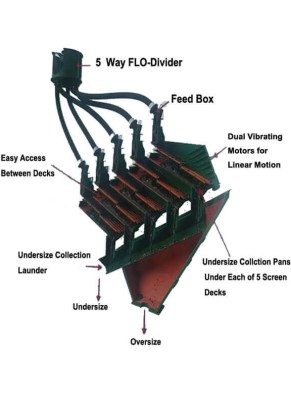

【5 Deck High-frequency Screen Structure】The high-frequency sizing screen mainly consists of a linear vibrator, upper screen box, feeding box, fixed frame, lower screen basket, high-frequency vibration system, upper and lower screen material collection funnels, shear springs, etc.

【5 Deck High-frequency Screen Working Principle】The high-frequency vibrating sizeris driven by two electric vibrators with opposite movement directions to drive the screen frame in a straight line. The resultant force of the two electric vibrators acting on the screen frame passes through the center of gravity of the screen frame. Therefore, the exciting force at each point on the screen frame is the same. The slurry is fed from the upper or lower part of the ore separator and evenly divided into multiple channels through the ore separator. Then it enters multiple ore feeders through the ore feeding hose. The ore feeder sprinkles the slurry evenly on the upper end of the screen surface. Due to the continuous vibration of high frequency and small amplitude, the materials on the screen surface make a continuous jump on the inclined screen surface to disperse the materials. In the process of mixing, the fine-grained materials pass through the screen hole and are called the products under the screen, while the materials larger than the screen hole make a continuous forward jump on the inclined screen surface, and finally jump out of the screen to become the products on the screen. High frequency and small amplitude vibration can destroy the surface tension of pulp and the adhesion of fine particles to coarse particles, making materials loose and layered. The screen surface adopts a polyurethane screen, with a high opening rate and good screening permeability, which can reduce and prevent screen hole blockage and improve screening efficiency.

Technical Parameters

| Stacked Vibrating Screen 5D-1216 | ||

| Item | Technical Parameters | Remarks |

| Screen Width | 1200 mm | |

| Screen Length | 1600 mm | |

| Screen Area | 9.6 m2 | |

| Processing Power | 25-35 t/h | Dry ore |

| Sieve Surface Form | Polyurethane screen | |

| Sieve Hole Size | 0.3 mm(50 mesh) | According to customer requirements |

| Number of Screen Layers | 5 | |

| Screen Inclination Angle | 18.5±2° | |

| Vibration Frequency | 25 Hz | |

| Amplitude | 1-2 mm | |

| Installed Power | Motor 2.2 kW | Dual motors total 4.4 kW |

| Feeding Method | Feeding box normal pressure feeding | |

| Mine Splitter | Single machine equipped with five-port mineral splitter | It is also equipped with a first-level mineral separator (one divided into four) |

Stacked Vibrating Sieve

| Model | Screening Size (m2) | Layer | Vibration Amplitude (mm) | Feeding Density (%) | Motor Power (kW) | Rotating Speed (r/m) | Lateral Slope (°) |

| 1216-1 | 1.92 | 1 | 1.33-2.61 | 30-40 | 2.2kw*2 | 1500 | 20 |

| 1216-2 | 3.84 | 2 | |||||

| 1216-3 | 5.76 | 3 | |||||

| 1216-5 | 9.6 | 5 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.