Vertical Ring High Gradient Magnetic Separator

【Capacity】0.01-150 TPH

【Feeding Size】0-1.2 mm

【Procesible Material】Quartz, feldspar, nepheline ore, kaolin, hematite, limonite, siderite, manganese ore, ilmenite, wolframite, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

A Vertical Ring High Gradient High-Intensity Magnetic Separator is a type of magnetic separation equipment used to purify non-metallic minerals and concentrate ores. It is designed to separate magnetic materials from non-magnetic materials efficiently.

Vertical Ring High Gradient Magnetic Separator VS Traditional Magnetic Separators

- High Gradient: It can generate a high-intensity magnetic field gradient, which allows for efficient separation even of weakly magnetic materials.

- High Capacity: It can handle large material throughputs due to its continuous operation and relatively high processing rates.

- Selectivity: It offers high selectivity for magnetic particles, allowing for precise separation and concentration.

- Compact Design: Its design is relatively compact compared to other magnetic separators, making it suitable for installation in existing processing plants.

The vertical ring high gradient high-intensity magnetic separator is used to separate weak magnetic minerals, such as hematite, limonite, siderite, chromite, titanic iron ore, scheelite, wolframite, manganese and tantalum-niobium ores, etc. It is used for iron separation from nonmetallic minerals, such as quartz, feldspar, nepheline, fluorite, sillimanite, spodumene, kaolin, etc.

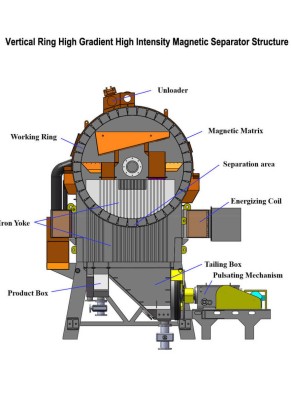

Product Structure

The vertical ring high gradient magnetic separator mainly comprises a pulsating structure, an excitation coil, an iron yoke, a rotating ring, various hoppers, and water hoppers.

Use round rods or expanded magnetically conductive stainless steel mesh as the magnetic medium. The excitation coil passes direct current to generate an induced magnetic field in the sorting area, and the surface of the magnetic medium located in the sorting area generates a non-uniform magnetic field, that is, a high gradient magnetic field; the rotating ring rotates clockwise to continuously transport the magnetic medium into and out of the sorting area; the pulp is fed from the feed The ore hopper is fed in and flows through the swivel along the gap in the upper iron yoke. The magnetic particles in the slurry are adsorbed on the surface of the medium, are brought to the top non-magnetic field area by the rotating ring, and are washed into the concentrate hopper by the flushing water; the non-magnetic particles pass through the magnetic medium pile under the action of gravity and pulsating fluid force and move along the bottom. The gaps in the iron yoke flow into the tailings bucket and are discharged.

Technical Parameters

| Model | Background Magnetic Field (T) | Feeding Material Size (mm) | Feeding Material Density | Dry Ore Capacity (t/h) | Pulp Throughout (m3/h) | Excitation Power (kW) | Swivel Power (kW) | Pulsating Power (kW) | Swivel Diameter (mm) | Water Consumption (m3/h) | External Dimensions |

| LH-500 | 0.6-1.4 | 0-1 | 10-30% | 0.01-0.05 | 0.25-0.5 | 6-20 | 0.18 | 0.55 | 500 | 0.65-1.4 | 1800*1400*1320 |

| LH-750 | 0.6-1.4 | 0-1 | 10-30% | 0.1-0.25 | 1-2 | 8-30 | 0.75 | 1.5 | 750 | 1.4-2.5 | 2000*1360*1860 |

| LH-1000 | 0.6-1.4 | 0-1.2 | 10-30% | 2-4 | 12.5-20 | 10-40 | 1.1 | 2.2 | 1000 | 8-12 | 2700*2000*2400 |

| LH-1250 | 0.6-1.4 | 0-1.2 | 10-30% | 5-10 | 20-50 | 12-50 | 1.5 | 3 | 1250 | 12-20 | 3200*2340*2700 |

| LH-1500 | 0.6-1.4 | 0-1.2 | 10-30% | 10-15 | 50-100 | 15.5-60 | 3 | 3 | 1500 | 20-30 | 3600*2900*3200 |

| LH-1750 | 0.6-1.4 | 0-1.2 | 10-30% | 15-20 | 75-150 | 23-72 | 4 | 4 | 1750 | 30-50 | 3900*3300*3800 |

| LH-2000 | 0.6-1.4 | 0-1.2 | 10-30% | 20-30 | 100-200 | 29-85 | 5.5 | 7.5 | 2000 | 50-100 | 4200*3550*4200 |

| LH-2500 | 0.6-1.4 | 0-1.2 | 10-30% | 45-60 | 200-400 | 37-98 | 11 | 11 | 2500 | 100-150 | 5800*5000*5400 |

| LH-3000 | 0.6-1.4 | 0-1.2 | 10-30% | 80-120 | 350-650 | 48-110 | 18.5 | 18.5 | 3000 | 150-250 | 7600*6500*7200 |

| LH-3600 | 0.6-1.4 | 0-1.2 | 10-30% | 100-150 | 500-750 | 72-180 | 30 | 30 | 3600 | 200-400 | 7700*6500*7600 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.