Filter Press Manual

Introduction, Application, Features & Types, How to Use

Introduction, Application, Features & Types, How to Use

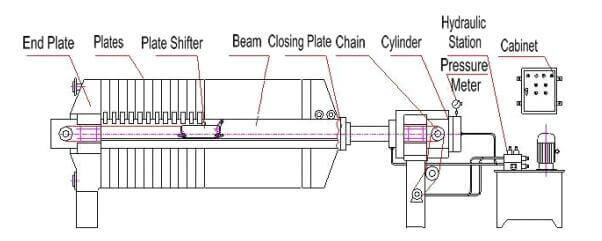

The correct installation and use of filter press, maintenance carefully, and strict compliance with the safety rules are the necessary conditions to improve the use efficiency of the equipment, prolong the service life of the equipment and ensure safety in production. So the operator should master the correct method of operation, and should also be familiar with the basic structure and filter principle, in order to improve production efficiency and avoid unnecessary equipment accidents or damage. Following we will introduce the manual for filter press.

The filter press uses a special filter medium to exert a certain pressure on the object to make the liquid dialyze out of a kind of mechanical equipment, which is a commonly used solid-liquid separation equipment. It is widely used in medicine, the chemical industry, standard parts, pharmaceutical, metallurgy, non-standard screws, dyes, food, brewing, ceramics, oil refining, sewage treatment, and other environmental protection industries.

The filter press is used the differential pressure on both sides of the filter cloth, forcing the most water of material through the filter cloth, the outflow of the machine, and the materials were blocked by the filter chamber to be filter cake, in that way, to achieve the purpose of filtering. Because during the filtration, there is a large pressure difference on both sides of the filter cloth, so improves the filtering speed and reduces the cake moisture rate, and the use of a special filter cloth, the filtrate is pure, and the filtering effect is match better than the vacuum filter.

JXSC Mine Machinery makes various filter presses, such as plate-and-frame filter presses, chamber type filter presses, vertical filter presses, belt filter presses, membrane filter presses, and so on. They are all can be customized. So if you need something that meets your individual requirements we are able to supply a filter press according to your wishes. Feel free to contact us!

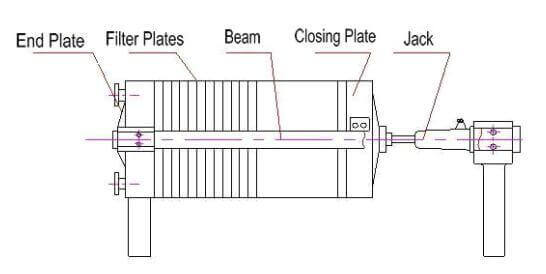

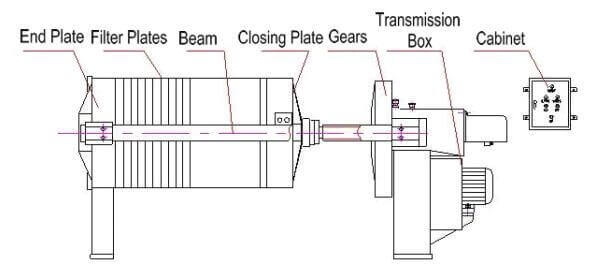

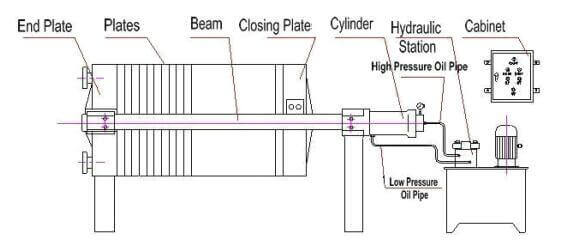

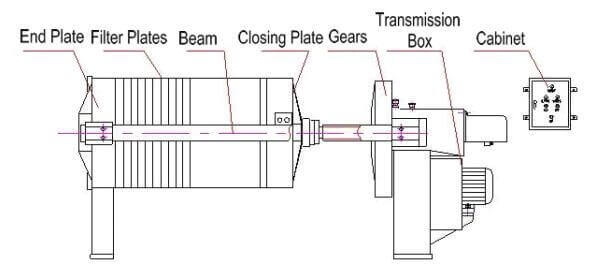

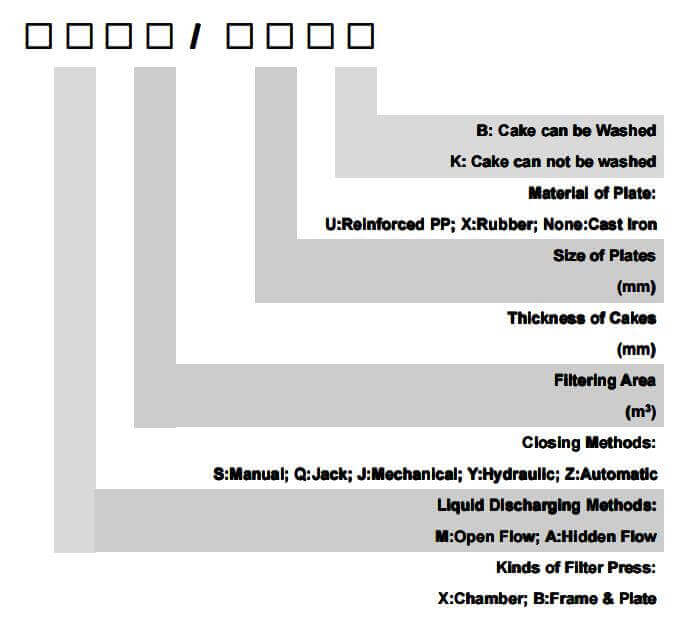

Our Filter Press Model Instructions

The filter press can be divided into many types according to different methods.

The Chamber of the plate frame filter press is consist of two plates and one frame (between both plates). This kind of filter press has the following advantages:

(1) Filter cloth can be easily installed and uninstalled.

(2) Besides filter cloth, additionally other filtering media can be added, such as filter paper, etc, to realize ultrafiltration.

With the development of plate technology, pate and frame are now combing together and chamber filter press become popular because chamber plates have the following advantages:

(1) Chamber plates can endure higher pressure.

(2) Convenient operation. Because of the two-in-one design, half-time of plate shifting can be saved.

(3) The feeding hole is in the center of the plate and the size is bigger, so blocking and bias pressure do not easily happen and can save a lot of filtering time.

Membrane plates are sandwich design and hollow. When feeding is finished, the membrane can be blown by compressed air (air source: air compressor), so that the final cake can be additionally squeezed to get the lower solid content.

The recessed plate is used CGR design to perfectly avoid leakage, it’s mainly used in some special fields, such as pharmaceuticals, rare metals, etc.,

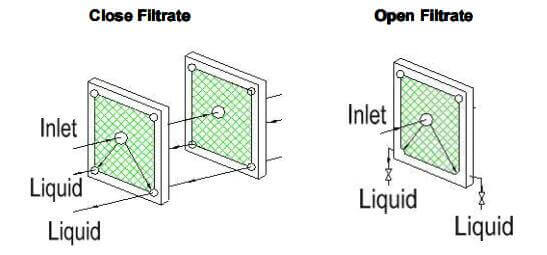

Close filtrate: filtered liquid is discharged via the pipe, which is consisted of the outlet of all plates. It is mainly used for special slurries, such as toxic, volatile, etc.,

Open filtrate: filtered liquid is discharged via the outlet on every plate. The open filtrate is widely used because if the filter cloth is damaged, it can directly find the problem soon. (If the filter cloth is broken, the liquid will be not clean. Please turn off the tap and repair the cloth after discharge.)

Before the operation, please check the followings:

1. The holes on the clothes math plates.

2. The feeding hole of the cloth is clamped by the filter cloth clip or sewn by a cloth tube.

3. The feeding hole on the plates and the holes on the cloth must be concentric.

4. The filter cloth must be flat and ensure no damage.

5. The cloth holes must little smaller than plate holes.