Slurry Pump

[Flow Capacity] 4.5-3300 m³/h

[Application] Mining, coal, metallurgy, chemical industry, environmental protection, sand dredging, river dredging, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The Slurry pump is a kind of centrifugal slurry pump used to convey suspended liquid containing sand, slag, etc. The impeller is mostly open. The pump lining is generally divided into two kinds, the wear-resistant metal box, and wear-resistant rubber. In addition, the high-pressure water is injected into the sliding part of the pump shaft to prevent the mud from entering the sliding part. The pump can be used for the solid liquid with a grain size above 48 mesh. The sand pump is used in mining, coal, metallurgy, chemical, and environmental industries. The slurry pump is important coal mining equipment.

Opencast mining is underground mining of tin, gold, tungsten-titanium-manganese ore, niobium-tantalum iron ore, Zircon, diamond, and even mining clay. short construction time, small investment, simple equipment, high productivity, low cost. JXSC slurry pump combines with other coal mining machines to engineer your application.

【Slurry Pump Selection】 Depending on different conditions, JXSC, a professional slurry pump manufacturer, provides a type of pump used for slurry the slurry pump/ sludge pump/ centrifugal slurry pump/ dirty water pump/ trash pump/ grinder pump, etc. to meet different tasks.

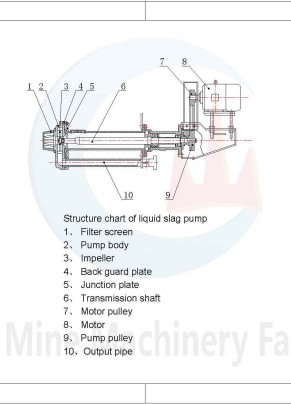

Product Structure

JXSC uses a special clamp to clamp the pump body and the pump cover, the direction of the pump output can be in any position of 360 degrees, the installation is convenient. Sand pump bearing components using cylindrical structure, easy to adjust the impeller and the clearance between the pump body, maintenance can be removed as a whole. Bearings are lubricated with grease. Sand pump shaft seal form packing seal, impeller seal, mechanical seal. Sand pump flow channel wide, good cavitation performance, high efficiency, wear-resistant. There are a v-belt transmission, elastic coupling transmission, gear reducer transmission, hydraulic coupling transmission, frequency conversion drive, silicon controlled speed, and so on. High hardness wear-resistant Alloy cast iron is used as the material of over-current parts.

Technical Parameters

ZJ Slurry Pump Parameters

| Model | Max. Power(Kw) | Capacity (m3/h) | Head(m) | Speed (r/min) |

| 40ZJ-I-A17 | 7.5 | 4.5-23.4 | 9.1-44.6 | 1400-2900 |

| 50ZJ-I-A46 | 55 | 23-94 | 17.9-85.8 | 700-1480 |

| 65ZJ-I-A30 | 15 | 23-79 | 7.4-34.8 | 700-1460 |

| 80ZJ-I-A36 | 45 | 46-190 | 9.6-51.4 | 700-1480 |

| 100ZJ-I-B42 | 90 | 83-365 | 12.7-66.8 | 700-1480 |

| 150ZJ-I-C42 | 132 | 142-550 | 12.1-62.8 | 700-1480 |

| 200ZJ-I-A65 | 250 | 235-950 | 16.4-72 | 490-980 |

| 250ZJ-I-A85 | 800 | 376-1504 | 30.1-128.7 | 490-980 |

| 300ZJ-I-A100 | 450 | 464-1826 | 15.3-65.2 | 300-590 |

| 350ZJ-I-C104 | 560 | 1335-3300 | 36.6-66.9 | 490-590 |

AH Slurry Pump(R) Parameters

| Model | Power(Kw) | Capacity (m3/h) | Head(m) | Impeller Ⴔ(mm) |

| 1.5/1B-A H | 15 | 12.6 ~ 28.8 | 6 ~ 68 | 152 |

| 10.8 ~25.2 | 7 ~ 52 | 330 | ||

| 2/1.5B-A H | 15 | 32.4 ~ 72 | 6 ~ 58 | 184 |

| 25.2 ~ 54 | 5.5 ~ 41 | 178 | ||

| 3/2C-A H | 30 | 39.6 ~ 86.4 | 12 ~ 64 | 214 |

| 36 ~ 75.6 | 13 ~ 39 | 213 | ||

| 4/3C-A H | 30 | 86.4 ~ 198 | 9 ~ 52 | 245 |

| 79.2 ~ 180 | 5 ~ 34.5 | 245 | ||

| 4/3D-A H | 60 | 97.2 ~ 198 | 9 ~ 53 | 245 |

| 79.2 ~ 180 | 5 ~ 34.5 | 245 | ||

| 6/4D-A H | 60 | 162 ~ 360 | 12 ~ 56 | 365 |

| 144 ~ 324 | 12 ~ 45 | 371 | ||

| 6/4E-A H | 120 | 162 ~ 360 | 12 ~ 56 | 365 |

| 144 ~ 324 | 12 ~ 45 | 371 | ||

| 8/6E-A H | 120 | 360 ~ 828 | 10 ~ 61 | 536 |

| 510 | ||||

| 8/6R-A H | 300 | 324 ~ 720 | 7 ~ 49 | 536 |

| 510 |

Submerged Slurry Pump Parameters

| Model | Match Power (KW) | Flow Capacity (m3/h) | Lift H(m) | Speed (r/min) | Impeller Diameter Ⴔ(mm) |

| 40PV-SP | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 188 |

| 65QV-SP | 3-30 | 18-113 | 5-31.5 | 700-1500 | 280 |

| 100RV-SP | 5.5-75 | 40-289 | 5-36 | 500-1200 | 370 |

| 150SV-SP | 11-110 | 108-576 | 8.5-40 | 500-1000 | 450 |

| 200SV-SP | 15-110 | 180-890 | 6.5-37 | 400-850 | 520 |

| 250TV-SP | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 575 |

| 300TV-SP | 22-200 | 288-1267 | 6-33 | 350-700 | 610 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.