Belt Scales

【Verification Accuracy】 ± 0.125% ~ ± 1%

【Belt Speed】 0~6m/s

【Belt Conveyor Inclination】0~30°

【Weighing Range】 0~8000t/h

【Belt Width】300~2400mm

【Application】 Mining, metallurgy, power plant, chemical industry, cement, building materials, and other industries

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

A belt scale is also called belt weigher, dynamic scale, conveyor scale, and in-motion weighing. It is used to continuously measure and report flow rates and totalized amounts of materials being transported on a conveyor belt.

【Belt Scales Types】

- Classified by carrier: weighing desktop carrier(A2-1), conveyor-type carrier(A2-2).

- Classified by belt speed: single-speed belt scale(B-1), multi-speed belt scale (b-2), and variable speed belt scale(B-3).

- Classified by weighing principle: mechanical type (commonly known as roller belt scale) and electronic type belt scale.

Mechanical/Roller Belt Scale

The mechanical belt scale is composed of a roller, gravity transmission system, counter, and speed plate. Among them, the rotational speed of the speed plate is proportional to the belt speed, the rolling angular speed of the roller, and the amount of material passing over the belt. Adjust the rolling position of the roller by the gravity of the material.

Electronic Belt Scale

The electronic belt scale, which is used for the scale frame structure of the load-bearing device can be divided into:

- Single/double idler belt scale

- Lever multi-idler belt scale

- Cantilever belt scale

- Suspended belt scale

Features

The metering section of the lever multi-idler and the suspension belt scales is relatively long, generally 2 to 8 sets of rollers. So their measurement accuracy is high. And they are suitable for weighing with large flow and high measurement accuracy.

The manufacturer can determine their belt speed for the single idler and cantilever belt scales. These two belt scales are more suitable for weighting with a small or controlled flow rate.

Applications

- Metallurgical industry: Calculate energy consumption for users.

- Port and wharf trade occasions: Provide users with accurate cargo weight data, improve the speed of cargo weighing and measurement, and increase trade economic benefits.

- Coal feeding in power plants: The electronic belt scale provides users with accurate coal consumption so that they can use it to calculate the coal consumption, grasp the input-output ratio, better formulate production plans, and reduce coal consumption.

- Coal mine: Mine explosion-proof electronic belt scale can be specially designed and manufactured according to the underground environment of the coal mine. It can apply it to the measurement of raw coal conveyed by belt conveyors in the underground coal mine to provide original and accurate output data for the output monitoring of coal enterprises.

- Transportation: It not only provides the measurement of loaded goods, but also integrates PLC and other technologies to create an automatic and fast loading/shipping system to achieve efficient and fast loading/shipping operations, avoid overloading, and reduce the transportation cost of enterprises.

JXSC supplies various belt scales and customized the conveyor belt scales for you. Such as the weight of the material transported is determined by weighing the belt load and measuring the belt speed. We can accord the clients’ requirement to manufacture the belt scale. Our electronic belt scales can automatically batch ingredients, avoid human interference and other factors, improve product quality and pass rate, reduce labor intensity, reduce production costs, improve production efficiency, and optimize the production environment.

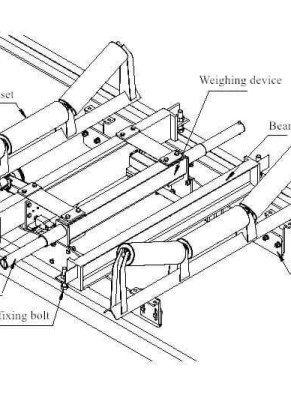

Product Structure

【Belt Scale Structure】

The electronic belt scale is composed of a steel mechanical scale frame, a speed sensor, a high-precision load cell, and an electronic belt scale control and display instrument. It can continuously and dynamically measure solid materials.

【Working Principle】

When weighing, the load-bearing device transmits the gravity of the material on the belt to the weighing sensor. The sensor outputs a voltage (mV) signal proportional to the gravity of the material. After amplifying the voltage signal, please send it to an A/D converter and converts it to a digital A. After the material speed is input to the speed sensor, the speed sensor outputs the number of pulses B. Send A and B to the calculator. Then we can obtain the amount of material in this measurement cycle. By accumulating each measurement cycle, the total amount of material continuously passing on the belt can be obtained.

Technical Parameters

| Model | 17A | 17B | ICS-17B | ICS-30A | ICS-30 | ICS-14A |

| Verification Accuracy | ± 0.25% | ± 0.5% | ± 0.25% | ± 1% | ±1% ~ ±0.125% | ±0.125% |

| Weighing Range | 0 ~ 6000t/h | 0 ~ 4000t/h | 0 ~ 6000t/h | 0 ~ 4000t/h | 0 ~ 8000t/h | 0 ~ 8000t/h |

| Belt Width | 500 ~ 2200mm | 500 ~ 2200mm | 500 ~ 2200mm | 300 ~ 2000mm | 500 ~ 2400mm | 500 ~ 2400mm |

| Belt Speed | 0 ~ 4.0m/s | 0 ~ 4.0m/s | 0 ~ 4.0m/s | 0.01 ~ 4.0m/s | 0 ~ 4.0m/s | 0 ~ 4.0m/s |

| Standard length of weighing area | 4800mm | 2400mm (can be changed according to the roller spacing) | 2400mm (can be changed according to the roller spacing), 300-120mm | |||

| Belt Conveyor Inclination | ≤18 ° | ≤18 ° | ≤18 ° | ≤6 ° | ||

| Working and installation environment | Temperature: Mechanical: -20°C/+50°C Meter: -10°C/+40°C Power: 220V AC (+10%, -15%) 50HZ ± 2% | Temperature: Mechanical: -20°C ~ +50°C Meter: 0°C ~ 40°C Power: 220V (+10%, -15%) 50HZ ± 2% |

Note: External dimensions can be customized.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.