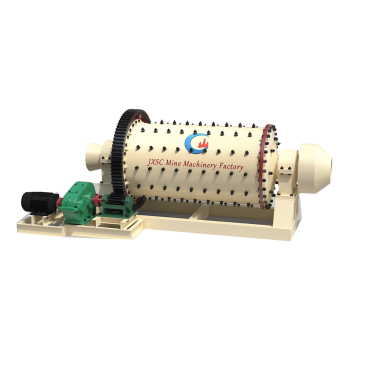

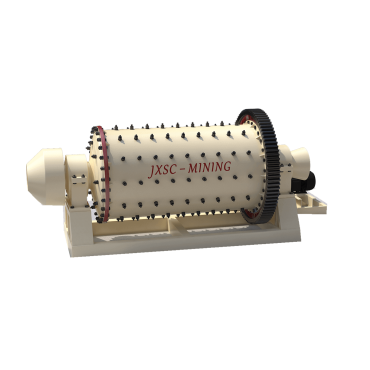

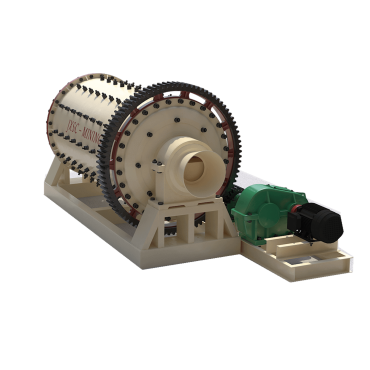

Ball Mills

【Capacity】 0.65-185 T/H

【Max Feeding Size】 <25 mm

【Discharge Size】0.074-0.89 mm

【Types】Overflow ball mills, grate discharge ball mills

【Advantages】Designed for long service life and minimum maintenance, it can grind and homogenize mineral ores down to the nano range, with a large processing capacity.

【Service】 24hrs quotation, custom-made parts, processing flow design & optimization, one-year warranty, on-site installation.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

A ball mill, also known as a ball grinding machine, is a well-known ore grinding machine widely used in mining, construction, and aggregate applications. JXSC started the ball mill business in 1985, supplying global services including design, manufacturing, installation, and free operation training.

【Type】 According to the discharge type, overflow ball mill, grate discharge ball mill; according to the grinding conditions, wet milling, dry grinding; according to the ball mill media.

【Wet Grinding】 Gold, chrome, tin, coltan, tantalite, silica sand, lead, pebble, and the like mining application.

【Dry Grinding】 Cement, building stone, power, etc.

【Grinding Media Ball】 Steel ball, manganese, chrome, ceramic ball, etc.

【Common Steel Ball Sizes】 40mm, 60mm, 80mm, 100mm, 120mm.

【Ball Mill Liner】 Natural rubber plate, manganese steel plate, 50-130mm custom thickness.

【Features】

1. Effective grinding technology for diverse applications.

2. Long life and minimum maintenance.

3. Automatization

4. Working Continuously

5. Quality guarantee, safe operation, energy-saving.

The ball grinding mill machine usually coordinates with other rock crusher machines, like jaw crushers, and cone crushers, to reduce the ore particle into fine and superfine sizes. Ball mill grinding tasks can be done under dry or wet conditions. Get to know more details about rock crushers, and ore grinders, contact us!

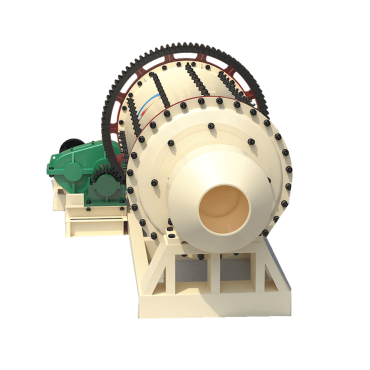

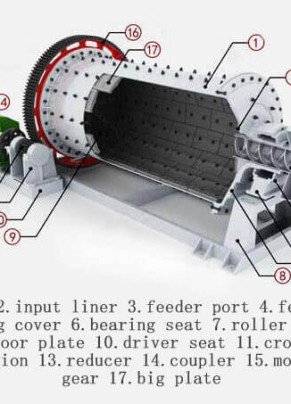

Product Structure

【Ball Mill Parts】 Feed, discharge, barrel, gear, motor, reducer, bearing, bearing seat, frame, liner plate, steel ball, etc. Contact our overseas office for buying ball mill components, wear parts, and your mine site visits.

【Ball Mill Working Principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits. Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel balls, or ceramic are used in the collision container. The ball milling process is prepared by rod mill, sag mill (autogenous / semi-autogenous grinding mill), jaw crusher, cone crusher, and other single or multistage crushing and screening.

【Ball Mill Manufacturer】 With more than 35 years of experience in grinding balls mill technology, JXSC design and produce heavy-duty scientific ball mill with long life minimum maintenance among industrial use, laboratory use. Besides, portable ball mills are designed for the mobile mineral processing plant. How much the ball mill, and how much invest a crushing plant? contact us today!

Find more ball mill diagram at ball mill PDF

【Service】Ball mill design, Testing of the material, grinding circuit design, on site installation. The ball grinding mill machine usually coordinates with other rock crusher machines, like jaw crusher, cone crusher, get to know more details of rock crushers, ore grinders, contact us! sag mill vs ball mill, rod mill vs ball mill

Technical Parameters

| Model | Drum Size(m) | Rotation Speed (r/min) | Ball Load(T) | Feeding Size(mm) | Output Size(mm) | Capacity(t/h) | Motor Power(kw) | Weight(t) |

| MQZ0918 | 0.9*1.8 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| MQZ0930 | 0.9*3.0 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| MQZ1224 | 1.2*2.4 | 36 | 5 | ≤25 | 0.074-0.6 | 1.5-4.8 | 37 | 12 |

| MQZ1230 | 1.2*3.0 | 36 | 6 | ≤25 | 0.074-0.4 | 1.6-5 | 45 | 12.8 |

| MQZ1245 | 1.2*4.5 | 32.4 | 7 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| MQZ1530 | 1.5*3.0 | 29.7 | 8 | ≤25 | 0.074-0.4 | 2-5 | 80 | 15.6 |

| MQZ1545 | 1.5*4.5 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 21 |

| MQZ1557 | 1.5*5.7 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| MQZ1836 | 1.8*3.6 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 155 | 28 |

| MQZ1845 | 1.8*4.5 | 27.24 | 18.5 | ≤25 | 0.074-0.4 | 4.5-12 | 180 | 32 |

| MQZ1864 | 1.8*6.4 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| MQZ1870 | 1.8*7.0 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| MQZ2136 | 2.1*3.6 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

| MQZ2145 | 2.1*4.5 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 42 |

| MQZ2170 | 2.1*7.0 | 23.7 | 26 | ≤25 | 0.074-0.4 | 12-48 | 280 | 50 |

| MQZ2245 | 2.2*4.5 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| MQZ2265 | 2.2*6.5 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

| MQZ2270 | 2.2*7.0 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| MQZ2275 | 2.2*7.5 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| MQZ2436 | 2.4*3.6 | 23 | 26.6 | ≤25 | 0.074-0.4 | 7-50 | 240 | 54 |

| MQZ2445 | 2.4*4.5 | 21.3 | 32 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| MQZ2740 | 2.7*4.0 | 20.7 | 40 | ≤25 | 0.074-0.4 | 22-80 | 380 | 94 |

| MQZ2745 | 2.7*4.5 | 21.88 | 48 | ≤25 | 0.074-0.4 | 26-90 | 475 | 102 |

| MQZ3245 | 3.2*4.5 | 18 | 65 | ≤25 | 0.074-0.4 | 35-100 | 630 | 137 |

| MQZ3645 | 3.6*4.5 | 17 | 90 | ≤25 | 0.074-0.4 | 40-120 | 850 | |

| MQZ3660 | 3.6*6.0 | 17 | 110 | ≤25 | 0.074-0.4 | 45-155 | 1250 | |

| MQZ3685 | 3.6*8.5 | 18 | 131 | ≤25 | 0.074-0.4 | 45.8-185 | 1800 |

How Many Types of Ball Mills?

1. Based on the axial orientation

A. Horizontal ball mill. It is the most common type supplied by ball mill manufacturers in China.

Although the capacity, specification, and structure may vary from every supplier, they are basically shaped like a cylinder with a drum inside its chamber. As the name implies, it comes in a longer and thinner shape form than vertical ball mills. Most horizontal ball mills have timers that shut down automatically when the material is fully processed.

B. Vertical ball mills are not commonly used in industries due to their capacity limitation and specific structure. A vertical roller mill comes in the form of an erect cylinder rather than a horizontal type like a detachable drum. The vertical grinding mill is only produced based on custom requirements by vertical ball mill manufacturers.

2. Based on the loading capacity

Ball mill manufacturers in China design different ball mill sizes to meet customers from various public administration sectors, such as colleges and universities, metallurgical institutes, and mines.

A. Industrial ball mills. They are applied in manufacturing factories, where they need to grind a huge amount of material into specific particles, and always interlink with equipment like feeders, and vibrating screens, such as ball mills for mining, ceramic industry, and cement grinding.

B. Planetary Ball Mills, small ball mill. They are intended for usage in the testing laboratory, usually come in the form of a vertical structure, have a small chamber, and have a small loading capacity.

Ball Mill for Sale

In all the ore mining beneficiation and concentrating processes, including gravity separation, chemical, and froth flotation, the working principle is to prepare fine-sized ores by crushing and grinding often with rock crushers, rod mills, and ball mills for the subsequent treatment. Over a period of many years of development, the fine grinding fineness has been reduced many times, and the ball mill machine has become the widest-used grinding machine in various applications due to its solid structure, and low operation cost.

The ball miller machine is a tumbling mill that uses steel milling balls as the grinding media, applied in primary or secondary grinding applications. The feed can be dry or wet, as the shell is dustproof for the dry materials process to minimize dust pollution.

Gear drive mill barrel tumbles iron or steel balls with the ore at a speed. Usually, the ball-filling rate is about 40%. The mill balls’ size is initially 30–80 cm in diameter but gradually wears away as the ore is ground. In general, the ball mill grinder can be fed either wet or dry. The ball mill machine is classed by electric power rather than diameter and capacity. JXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 18.5-800KW. During production, the ball grinding machine may be called a cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc.

JXSC ball mills are designed for high capacity long service, and good quality matches Metso ball mills.

Grinding Media

Grinding balls for mining usually adopt wet grinding ball mills, mostly manganese, steel, and lead balls. Ceramic balls for ball mills are often seen in the laboratory.

Types of ball mills: wet grinding ball mill, dry grinding ball mill, horizontal ball mill, vibration mill, large ball mill, coal mill, stone mill grinder, tumbling ball mill, etc.

The ball mill barrel is filled with powder and milling media. The powder can reduce the ball’s falling impact, but if the power is too much that may cause balls to stick to the container side. Along with the rotational force, the crushing action mill the power, so, it is essential to ensure enough space for media to tumble effectively.

How Does Ball Mill Work?

The material is fed into the drum through the hopper, motor drive cylinder rotates, causing grinding balls to rise and fall following the drum rotation direction. The grinding media is lifted to a certain height and then falls back into the cylinder and onto the material to be ground.

The rotation speed is a key point related to the ball mill efficiency, rotation speed is too great or too small, and neither brings a good grinding result. Based on experience, the rotation is usually set between 4-20/minute. If the speed is too great, may create centrifuge force thus the grinding balls stay with the mill perimeter and don’t fall. In summary, it depends on the mill diameter. The larger the diameter, the slower the rotation (the suitable rotation speed adjusted before delivery).

What Is The Critical Speed of The Ball Mill?

The critical speed of the ball mill is the speed at which the centrifugal force is equal to the gravity on the inner surface of the mill so that no ball falls from its position onto the mill shell. Ball mill machines usually operate at 65-75% of critical speed.

What Is The Ball Mill Price?

Many factors affect the ball mill cost; kindly let me know the following basic information for quicker quotations.

(1) Application, What is the grinding material? (2) Required capacity, feeding, and discharge size (3) Dry or wet grinding (4) Single machine or complete processing plant, etc.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.