Placer Gold Mining

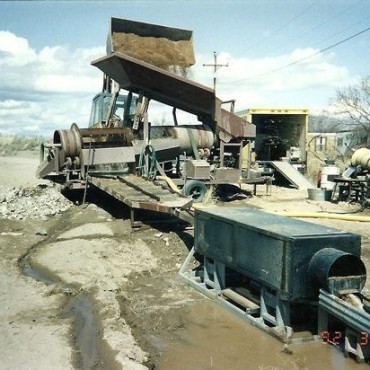

Placer gold mining mainly refers to mining from the land surface, river, or underground. Has various types of gold raw material: alluvial gold/placer gold/sand gold/river gold/ gold tailing, etc. The placer gold mining equipment includes feeding, washing, sieving, rough separation, final concentration, and refining. Because the gold density is much bigger than other minerals, so mainly use gravity separation.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

Gold Mining Plant is mainly mined from land surface or river or underground. Has various types of gold raw material: alluvial gold/placer gold/sand gold/river gold/ gold tailing, etc. The main process includes feeding, washing, sieving, rough separation, final concentration, and refining. Because the gold density is much bigger than other minerals, so mainly use gravity separation.

We strive to bring all these gold mining equipment to you. Whether you’re planning for gold, wanting to use locks or senior bankers in a stream, using a dry cleaner in a dry area, moving a drum of material, or a gold panning machine to save your muscles, or panning a detector, you’ll find a lot of choices and information.

Product Structure

Feeding: Various kinds of feeding methods, depending on the plant and material conditions. Have choices of vibration feeder, hopper, belt feeder, wheel loader, and excavator feed directly. Usually will make some grizzly bars on the feeding machine or hopper to remove big waste stones.

Washing: This process is to wash and clean the clay and mud in raw material. The most popular users are the gold trommel scrubber washer and gold washing trommel screen.

Gold trommel scrubber is for washing raw material with much sticky clay, and trommel screen is for washing raw material with no sticky clay.

Sieving: After washing, need to sieve out some bigger waste material. The under-screen slurry will go to the next machine. This process can use trommel, vibration, or high-frequency screens.

Primary concentration: This process is for rough gold concentration, and can use a gold centrifugal concentrator or jig separator. The concentrated ore from them will go to the final concentration machine.

Final Concentration: The concentrated ore from the jig machine or centrifugal will go to a gold shaking table for the final concentration, which can get high-purity gold.

Tailing recovery: Usually, a gold sluice box is used to recover tailings from the centrifugal machine. So can get more gold.

Refining: If some customer needs very very high purity gold and need to smelt to the gold bar for sale, they can use a gold smelting furnace to smelt gold dust to a gold bar.

The most effective process flowchart and most suitable equipment types are always recommended per the customer’s request and gold ore conditions and process capacity.

Technical Parameters

The parameters of each equipment are selected according to the processing capacity of the concentrator.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.

.jpg&w=291;&h=404;&zc=1)