Jig Concentrator

【Capacity】 1-25 T/H

【Feeding Size】 <25 mm

【Type】 Wet separation, dry separation

【Application】 Jig concentrator is a gravity separator machine used to separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, garnet, etc.

【Service】 Support for custom, on-site installation, one-year warranty; processing flow design & optimization.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【Jig Concentrator】 is an effective gravity separation machine based on the ore material density difference. The jigging machine is mainly used for processing placer gold, coltan, tungsten, tin, etc., The higher the density difference, the better the jigging separation effect.

【Type】 Eccentric jig concentrator (plunger jig and diaphragm jig), hydraulic jigger, movable sieve jig, air pulsating jig, trapezoid jig. The diaphragm jig has high beneficiation efficiency and can process coarse particle ore, separate tungsten, tin, and the like with a particle size of up to 16 mm and a minimum particle size of 0.5 mm.

The trapezoidal jig has a large processing capacity and a wide particle size of 50-0.25 mm. It has been promoted and used in tungsten, tin, and iron ore dressing plants. According to the beneficiation medium, the mineral jig is divided into the hydraulic jig and dry jig, dry material feeding has a better result.

【Features】 The JXSC sawtooth jig machine adopts water as the medium and has a good effect on fine gold recovery, low water consumption, and continuous operation.

【Related Machines】 Before the jig saw machine: feeding by belt conveyor, slurry pump, or gravity flow automatically based on the height difference. After jig saw machine: gold concentrate ⇒ gold shaker table, tailings ⇒ sluice box.

【Jig Separator Manufacturer】JXSC supplies different types of jigging in mineral processing(such as fixed jig and mobile jig machine), the customized parameters for your requirements. JXSC has focused on the gravity separation mineral processing technique for decades, more gravity separator machines: spiral chute, jigger machine(mineral jig concentrator), shaker table, and centrifugal concentrator.

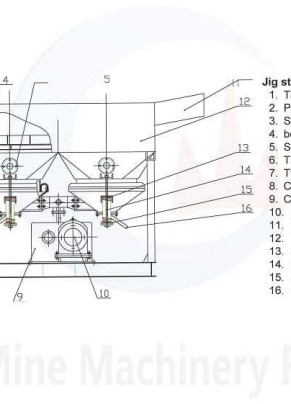

Product Structure

【Jig Concentrator Working Principle】 The mixture of mineral particles of different specific gravities is layered by specific gravity in a vertically moving variable-speed medium flow (water or air). The ore particles with a small specific gravity are located in the upper layer, and the larger ore particles are located in the lower layer, and then they are separated into products of different specific gravity by mechanical action and water flow, and are respectively discharged.

【Mineral Bed】 Usually pave a 10-15cm mineral bed by using iron ore ( 50% grade ). JXSC engineer will help you to determine the bed thickness, iron size, screen mesh, and adjust the stroke, stroke frequency before delivery.

【Factors Affecting Mineral Jig Beneficiation】

(1) Stroke and stroke times. The stroke and stroke times determine the speed, acceleration and looseness of the layer in the jig. High stroke and small times better for coarse material, low stroke and high times for fine particle size.

(2) Water consumption. The larger the water volume, the faster the light product discharge and the larger the capacity, but the stratification is incomplete, and the light products are easily mixed into the larger specific gravity.

(3) Material layer thickness. The thicker the layer, the longer it takes for the layer loosing, thus longer separation time.

When the bed is thick, the quality of the heavy product is improved and the quality of the light product is lowered. When the bed is thin, the quality of the heavy product is lowered and the quality of the light product is improved.

(4) The size of the screen of the jig, screen mesh and shape, feeding amount and uniformity.

Technical Parameters

| Model | Jigging Chamber | Diaphragm | Feeding Size (mm) | Back Wash Water(m3/h) | Back Wash Water Pressure (Mpa) | Capacity(T/H) | Power(KW) | Dimensions (mm) | Weight (T) | ||

| Shape | Jig Area (M2) | Stroke | Jig Frequency | ||||||||

| JT0.57-1 | Trapezoid | 0.57 | 10-17 | 80-120 | <10 | 18-20 | ≥0.1 | 1-3 | 1.5 | 1500*780*1530 | 0.6 |

| JT1-1 | Rectangle | 1.1 | 10-17 | <10 | 20-30 | 2-5 | 2.2 | 2270*1110*1890 | 0.9 | ||

| JT2-2 | Rectangle | 2.3 | 10-17 | 60-100 | <25 | 40-50 | 4-8 | 3 | 2900*1550*2000 | 1.4 | |

| JT4-2 | Rectangle | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 7.5 | 3900*2000*2460 | 3.2 | ||

| JT4-2A | Rectangle | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 4*2pcs | 3900*2000*2460 | 4 | ||

| JT5-2 | Trapezoid | 5 | 20-30 | <25 | 80-100 | 10-20 | 7.5 | 4000*2050*2600 | 3.2 | ||

| JT6-3 | Rectangle | 6.8 | 20-30 | <25 | 120-150 | 20-25 | 7.5+4 | 5400*2000*2460 | 5 | ||

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.