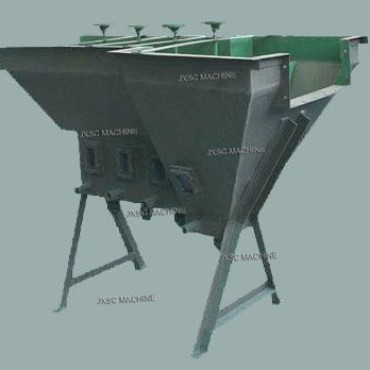

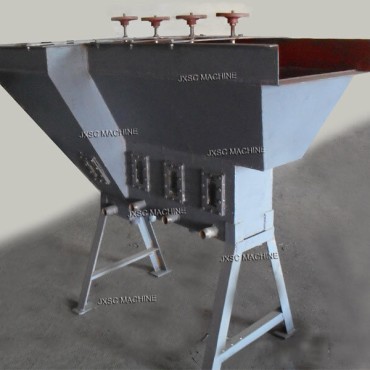

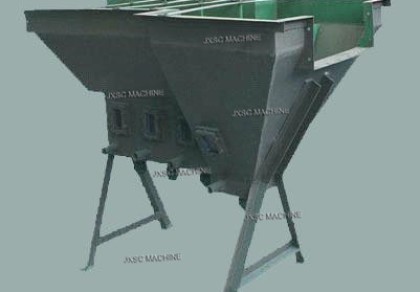

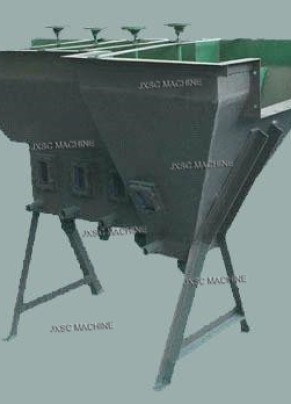

Hydraulic Classifier

The hydraulic classifier uses sieve-plate subsidence caused by interference in the term of equipment. the body shape for the corner of the cone-shaped boxes, boxes with vertical partitions into 4-8 graded rooms. each room has an area of 200 mm*200 mm. away from the room at the end of a certain height to set the sieve.

Hydraulic classifier has the advantage of simple structure, no momentum, and is easy to configure.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【Features & Advantages 】Hydraulic classifier widely used in the shaker table sorting before hydraulic grading homework, play classification, and distribution of ore reserves, to improve the separation efficiency of the shaking table. Hydraulic classification box has the advantages of simple structure, convenient maintenance, no power consumption, reliable performance, convenient operation, and so on.

According to the different processing capabilities, it can be made of four rooms, six rooms, and 8 rooms of different specifications. The equipment used for sorting iron, tungsten, tin, gold, and non-ferrous. ferrous metal mine.

Hydraulic classification, also known as hydraulic classifier/ hydro-classifier/ hydrosizer/ tank-type hydraulic classifier/ mining hydraulic classifier/ gold mining hydraulic classifier/ mineral hydraulic classifier/ gold processing hydraulic classifier/ size grading machine/ classification equipment.

The sieve-plate trough hydraulic classifier, also known as the Denver Hydraulic classifier, is the equipment that uses the sieve plate to cause the interference settlement condition. The body shape is a pyramid-shaped box, divided into 4 ~ 8 classification rooms by a vertical partition board. The sectional area of each chamber is 200 mm. A sieve plate is arranged at a certain height away from the bottom of the chamber.

Find more ore classifying machines

Product Structure

There are 36 ~ 72 holes with a diameter of 3 ~ 5 mm on the sieve plate. The pressure water is fed under the sieve plate and flows up through the sieve hole. The ore particles are suspended above the sieve plate, and the interference settlement is carried out. The coarse particles are discharged through the central hole of the sieve plate, and the discharge is controlled by a conical plug.

The slurry is fed into each chamber by one side, and the ascending velocity of the water in each chamber decreases gradually, and the products from coarse to fine are obtained. The distribution of rising water velocity in the chamber has an important influence on the classification effect. The effect can be improved to a certain extent by reducing the size of the sieve holes and increasing the number of sieve holes accordingly. But the uneven distribution of water speed is inevitable. The main reason for the low efficiency of secondary backflow agitation.

The advantages of the sieve-plate hydraulic classifier are simple structure and no need for power. Compared with the mechanical stirring type hydraulic classifier, the height is smaller and it is easy to configure. It can be made into four chambers according to the different processing capacities of the concentrator. Six rooms, eight rooms and so on different specifications. The classifier is widely used in middle and small tungsten concentrators in China.

Technical Parameters

| Model | Feed Size(mm) | Feed Density | Increase In Water Pressure | Sieve Size(mm) | Capacity (t/h) | Overall Dimension(mm) |

| 240*240 | 0-3 | 20%-26% | 150-200 | 240*240 | 5-8 | 1818*1138*1680 |

| 200*200 | 0-3 | 20%-26% | 150-200 | 200*200 | 4-5 | 1650*1100*1600 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.