Attrition Scrubbers

【Feeding Size】≤5 mm

【Motor Power】11-180 kW

【Volume】 1-12 m³

【Feeding Density】 50%-60%

【Application】 It’s used in glass sand, frac sand, mineral sand, clay, iron ore, and sand and gravel production. It is mainly used to distribute mineral mud and remove mineral surface impurities.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The attrition scrubber is also called attrition cell, attrition tank, or attrition machine. It is used to scrub the pulp with a concentration of 65-70% and to scrub the mud and fine sand on the ore. Dispersing the slime in ores to remove the impurities on the ore surface can create conditions for subsequent mineral processing and is an important part of the mineral processing production line. It can also be widely used in other industrial areas of scrubbing operation.

Attrition scrubbers are generally used before or after sand screws in a sand washing plant to scrub the surfaces of particulates, break down impurities, and remove them from competent aggregate material to reduce the product turbidity. The attrition tank is mainly used in non-metallic minerals such as quartz, feldspar, silica, and river sand. We design single and multiple cell attrition scrubber units for different scrubbing requirements of mineral materials.

The attrition machine applicants in the cleaning of silica sand for glass making, the liberation of minerals from slime coatings, the disintegration of clay agglomerates, separation of sand grains from cement minerals, high-intensity conditioning, efficient lime slaking, etc.,

【Features】1.Low power consumption, strong scrubbing ability. 2. Ease of operation, lower operating and maintenance cost. 3. Simple structure, large effective volume, and small occupation area. 4. Minimal wear, longer life.

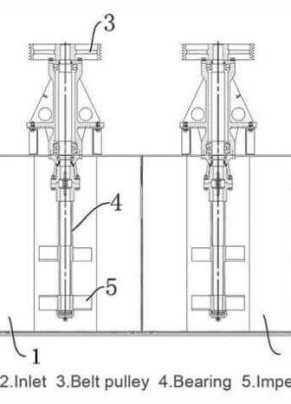

Product Structure

Attrition Scrubber Structure: The attrition cell is consist of a tank, impeller system, and drive system. Generally, the tank is PE lined and can be either square or octagonal. The impeller system is PE coated and normally consists of two sets of impellers with opposing pitchers. The v-belt drive system is designed to effectively transmit the power to spin the shaft and impellers. The most important function of the attrition machine is the scrubbing of particle surfaces to remove film or coating.

Attrition Scrubber Working Principle: The motor drives the main shaft to rotate through the belt pulley, causing a negative pressure area on the blade. After Silica and quartz sand slurry (density of 60%~75%) into the scrubbing machine, it is stirred and rinsed thoroughly, and then pushed out by the blade and flows along the wall of the barrel. As the material is continuously sent in, the cleaned material is constantly discharged from the discharge port to finish the scrubbing work. The ore slurry enters the chamber through the feeding pipe. Under the strong stirring action of the impeller, the negative pressure zone is generated in the blade. When the ore pulp passes through, it is stirred and rinsed thoroughly, and then pushed out by the blade to flow along the wall of the barrel.The ore pulp particles generate enormous momentum and cause violent friction and collision with each other.The impurity film wrapped on the surface of particles is easy to be separated from the ore surface by friction and impact. The adglutinate on the ore surface is soaked by water and then through the intense friction and collision between the ore particles, the adglutinate will also be loose and broken down, so as to achieve the separation of clay and ore particles.These film impurities and clay are broken down and flaked into the slurry, which can be separated after subsequent desliming.

Technical Parameters

| Model | Volume(m³) | Feeding Size(mm) | Feeding density(%) | Motor Power(kw) | Dimension L*W*H(mm) | Weight(kg) |

| GSC1-1 | 1 | ≤5 | 50-60 | 11 | 1420x1310x1860 | 1300 |

| GSC1-2 | 2 | ≤5 | 50-60 | 11×2 | 2340x1310x1860 | 2500 |

| GSC2-1 | 2 | ≤5 | 50-60 | 30 | 2150x1900x2780 | 3200 |

| GSC2-2 | 4 | ≤5 | 50-60 | 30×2 | 3530x1900x2780 | 5300 |

| GSC4-1 | 4 | ≤5 | 50-60 | 55 | 2596x2800x3441 | 3800 |

| GSC4-2 | 8 | ≤5 | 50-60 | 55×2 | 4430x2800x3441 | 7500 |

| GSC6-2 | 12 | ≤5 | 50-60 | 90×2 | 4900x3200x4100 | 9500 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.