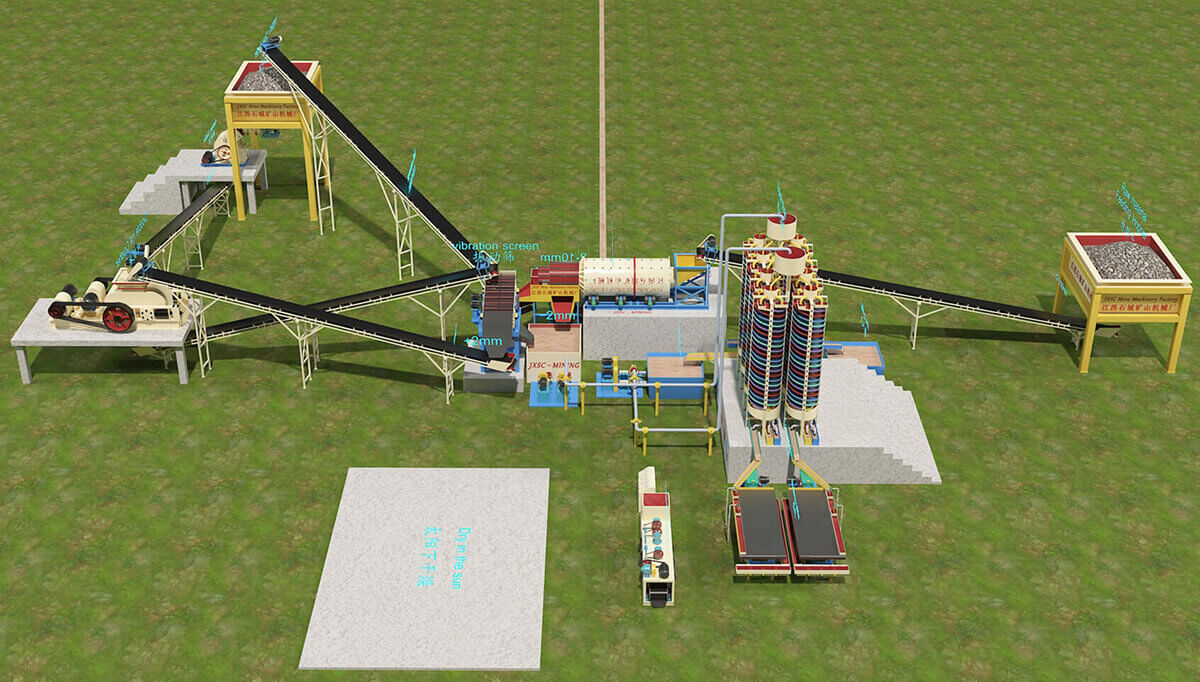

JXSC has designed a complete Flowchart and provides a complete set of processing plant machines & all accessories for Zimbabwe’s mixed rock tin tantalite ore processing plant in Zimbabwe. The client has their engineering team set up this plant, so there is no requirement for our engineering site service. We offer a detailed layout design with base construction drawings accordingly.

20TPH Mixed Rock Tin Tantalite Ore Processing Plant in Zimbabwe

Published Date:22 January 2024Client’s Mine Situation

- Raw ore contains clay and needs washing.

- The processing capacity required is 20tph.

- The maximum feeding size of raw ore is less than 100mm.

20TPH Mixed Rock Tin Tantalite Ore Processing Plant 3D Flowchart

Tin Tantalite Ore Processing Plant Equipment

- Hammer Crusher

- Trommel scrubber

- High-frequency vibration screen

- Belt conveyor

- Jig separator

- Spiral chute

- Chute Feeder

- Roller crusher

- 3pcs magnetic separator

- Shaking table

Flowchat Description

- For the loader or excavator feed to one hopper, we use a belt conveyor to feed the material to the trommel scrubber for washing and screening the raw ore. 0-2mm stone will be put into a pulp pool, and 2-10mm stone will be put into a jig separator to select 2-10mm tin concentrate.

- Use the belt conveyor to transport the more than 10mm stone to storage. Then, use a forklift to feed the stone to a hopper and a chute feeder to feed the stone to a hammer crusher; the stone will be 10mm after crushing. Then use a belt conveyor to transport it to the roller crusher to crush it again to 2mm, then use the belt conveyor to transport it to the high-frequency screen to screen out the sand of more than 2mm, and use the belt conveyor to transport it back to the roller crusher to crush it again.

- After the screen, the 0-2mm sand will flow into the pulp pool(the same pool as the discharge of the trommel scrubber 0-2mm). A slurry pump feeds the spiral chute’s 0-2mm sand.

- Use a two-stage spiral chute; the first stage processes 0-2mm sand; the spiral chute has three discharges: concentrates, middlings, and tailings. Then, use a slurry pump to pump the middlings to the next stage to recover. Then, the tantalum concentrates of two-stage spirals are put into a shaking table to recover fine tantalum.

- Dry the tin in the sun, and then use a 3pcs disc dry magnetic separator to separate the tin, tantalite, and iron.

Production & Shipping

JXSC is a professional mining equipment manufacturer & mining ore solution expert. It has many successful cases such as gold plants, diamond solutions, etc., If you need such a service please contact us.

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.