JXSC has designed a complete Flowchart and provides a complete set of processing plant machines & all accessories for Brazil’s customer alluvial gold & columbite processing plant in Brazil. The client has their engineering team set up this plant, so there is no requirement for our engineering site service. We offer a detailed layout design with base construction drawings accordingly.

100TPH Alluvial Gold & Columbite Processing Plant in Brazil

Published Date:24 November 2023Client’s Mine Situation

- The raw ore contains a lot of slime.

- The raw material is an alluvial type.

- The feeding material size is less than 120 mm.

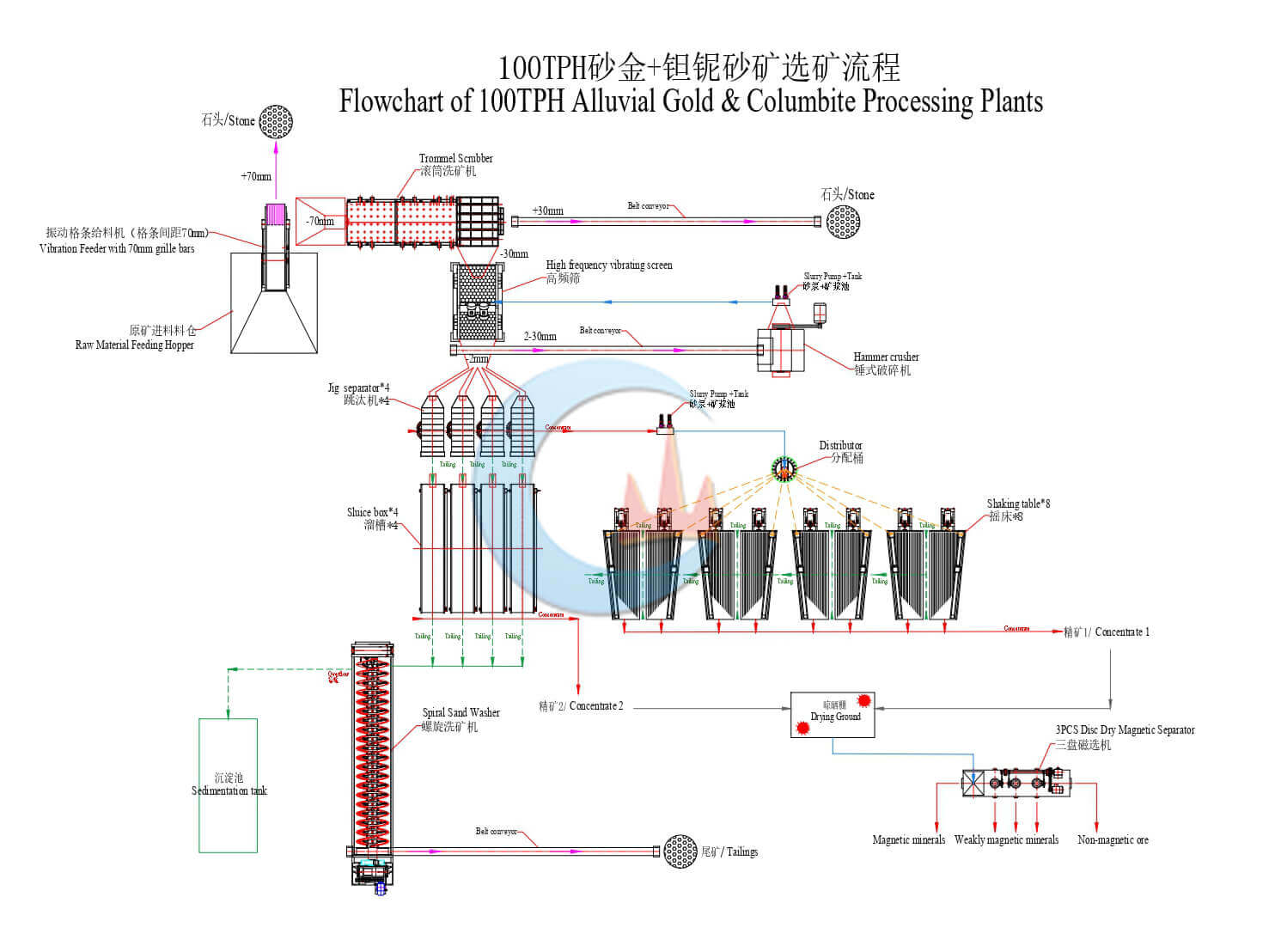

100TPH Alluvial Gold & Columbite Processing Plant Flowchart

Alluvial Gold & Columbite Processing Equipment

- Vibration feeder

- Trommel scrubber

- High-frequency vibration screen

- Belt conveyor

- Hammer Crusher

- Jig separators

- Sluice boxes

- Slurry pump

- Shaking table

- Spiral sand washer

- 3pcs disc dry magnetic separator

Flowchat Description

- The plant will begin with a 70mm grizzly bar from the vibration feeder. Less than 70mm of materials will go to the trommel scrubber to wash. Since there’s a lot of sticky in the raw ore, we suggest using a trommel scrubber to wash away the sticky clay.

- The scrubber has a one-layer screen size of 30mm; the screen material can be manganese or PU. The more than 30mm materials will be sent away by a belt conveyor. The less than 30mm materials will go to a high-frequency vibration screen with a 2mm screen.

- The 2-30mm materials will be sent to the hammer crusher by belt conveyor to crush to be smaller, like less than 2mm. Then use a slurry pump to send the slurry back to the high-frequency vibration screen to screen again.

- The less than 2mm materials will go to several sets of jig separators to do the first-time separation. The concentrate will be separated and gathered under the screen in the jig. The screen size in the jig can be 2mm.

- The concentrate from the jig under the screen will be sent to the shaking table. After separating them by the shaking table, you can gather them and send them to the drying ground.

- The materials above the jig screen are tailings and some gold nuggets. They’ll go to the sluice box. The carpet will catch the gold nuggets and some fine-sized columbite.

- Then the tailings from the sluice box will go to a spiral sand washer for dewatering so that you can process the tailings more easily.

- Suppose there are too many magnetic ores(like magnetite, hematite, etc.) inside your concentrate ores after you dry them. In that case, you can send them to the 3pcs disc dry magnetic separator to remove the magnetic materials and get the final concentrated columbite ores.

The capacity for this plant can be customized as per request such as 30tph, 40tph,100tph, etc.

Production & Shipping

JXSC is a professional mining equipment manufacturer & mining ore solution expert. It has many successful cases such as gold plants, diamond solutions, etc., If you need such a service please contact us.

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.