This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > Spare Parts > Impact Crusher Parts

Impact Crusher Wear / Spare Parts

The impact crusher can be used not only as the first primary crusher but also as the second and third crushers. It can process materials with a side length of 100-500 mm and crush stones below medium hardness, such as granite, pebbles, limestone, quartz, coal mines, and other materials. The impact crusher has the advantage of a large crushing ratio, and the crushed material is in the form of cubic particles. They are used in building materials, ore crushing, railways, highways, energy, transportation, cement, mining, chemical, and other industries for medium and fine crushing materials. The discharging granularity can be adjusted, and the crushing specifications are diversified.

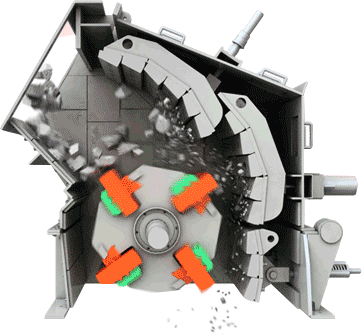

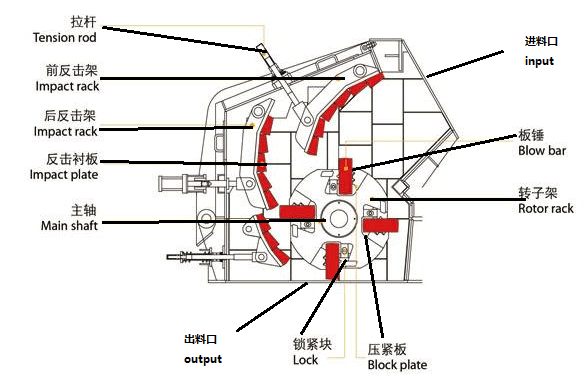

An impact crusher is a crushing machine that uses impact energy to crush materials. The rotor rotates high speed when the machine is working, driven by the motor. When the material enters the blow bar area, it collides with the blow bar on the rotor and breaks, then is thrown to the impact device to be crushed again, and then bounces off the impact liner. Go back to the action area of the blow bar for re-crushing. The material enters the first, second, and third impact chambers from large to small for repeated crushing until the material is crushed to the required particle size and discharged from the discharge port.

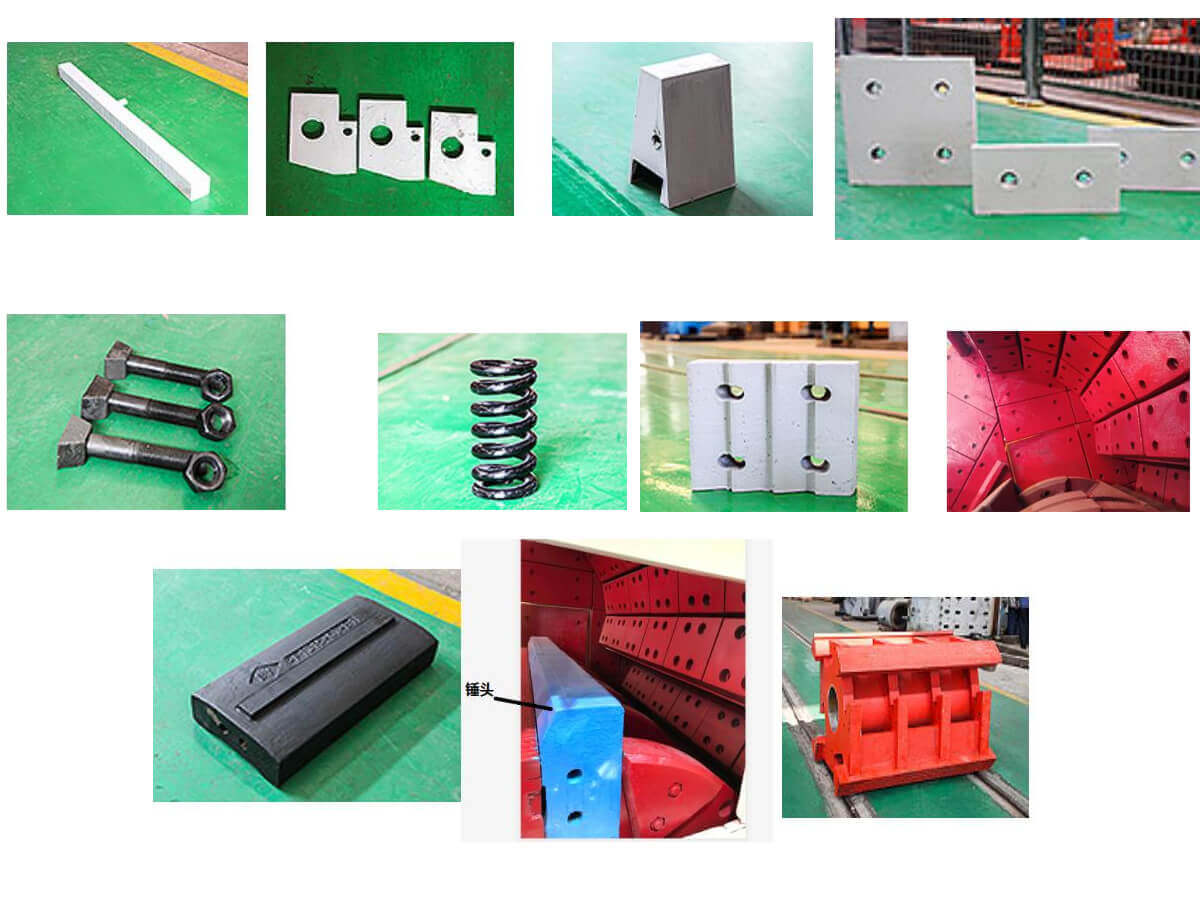

The common wearing parts of impact crushers mainly include blow bars, side liners, impact plates, breaker plates, rotor, bearing, flat head bolt, spring, etc.,

Blow Bars(Hammers)

The blow bar is one of the primary wearing parts of an impact crusher. And it is made of high chromium alloy.

We produce blow bars using the latest manufacturing techniques and unique structural designs. Our blow bar has a cubic shape, no tension and cracks, and a pretty good grain shape, which is a reliable high wear-resistant casting.

When the blow bar is worn to a certain extent, it should be adjusted or replaced in time to avoid damage to fasteners and other components.

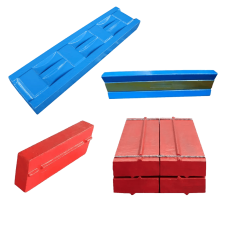

Impact Plates(Wear Liner)

The impact plate (wear liner) is the second vulnerable part in the impact crusher to the blow bar, which can protect the machine and reduce wear.

The impact plate’s shape, structure, and casting material greatly influence the impact-breaking efficiency and service life.

Suppose the impact plate with high wear resistance and impact resistance is adopted. In that case, it can not only prolong the service life of the impact crusher but also improve the production capacity of the impact crusher.

Side Liners

The side liners are also called frame liners, these are used on the inside of the impact or body to protect it from wear.

Rotor

This is the main part of the HSI crusher. It holds the blow bars and rotates at high speed, driven by a pulley connected directly to the engine.

Impact Crusher Parts

| Brand | Series | Model |

| METSO | Nordbe NP | NP1110, NP1213, NP1313, NP1315, NP1415, NP1520, NP1620, NP2023, BP13, NP15, NP20 |

| TEREX | Powerscreen | 230, 230SR, 320, 320SR, 550, 550SR |

| Lokotrack | LT | LT1110, LT1213, LT1213S, LT1315, Nordtrack I908S |

| KLEEMANN | MR | MR 110 Z EVO2, MR 122 Z, MR130 Z EVO2, MR 150 Z, MR 170 Z |

| KLEEMANN | MF | MF 14 S, MF 16S, |

| ROCKSTER | R700S, R900, R1000S, R1100S, R1100DS | |

| TEREX FINLAY | I | I-140, I-140RS, I-120, I-120RS |

| TEREX FINLAY | IC | IC-110, IC-110RS, IC-100, IC-100RS |

| STRIKER | HQ | HQ907, HQ910, HQ1112, HQ1312, HQR907, HQR910, HQR1112, HQR1312 |

| TESAB | 623CT, 1012T, 1012TS, 1412T | |

| McCloskey | I44v3, I44Rv3, I54v3, I54Rv3, I34, I34R | |

| HAZEMAG | HPI-H | HPI-H 1010, HPI-H 1214, HPI-H 1414, HPI-H 1615, HPI-H 1618 |

| HAZEMAG | HPC | HPC-1414, HPC-1615, HPC-1618, HPC-1622, HPC-1822, HPC-2022, HPC-2025, HPC-2030 |

| HAZEMAG | HSI | HSI 1007, HSI 1010, HSI 1014, HSI 1414, HSI 1420, HSI 1625, HSI 1630 |

| HAZEMAG | HTI | HTI 1005, HTI 1010, HTI 1014 |

| HAZEMAG | HPI | HPl-1622, HPI-1822, HPI-2022, HPI-2025, HPI-2030, HPI-2225*, HPl-2230, HPl-2530 |

| EAGLE CRUSHER | UM-04, UM-05, UM-15, UM-25, UM-45, UM-69 | |

| RUBBLE MASTER | RM 60, RM 70GO!2.0, RM 90GO!, RM 100GO!, RM 120GO!, RM V550GO! | |

| POWERSCREEN | TRAKPACTOR 230, TRAKPACTOR 230SR, TRAKPACTOR320 & 320SR, TRAKPACTOR 550, TRAKPACTOR 550SR |

Why Choose Us?

Wear And Spare Parts for Sale

Crusher Parts

- Cone Crusher Parts: Bowl liners, concaves, mantles, feed cones, main frame liners, seat liners, distribution plates, lock nuts, and so on.

- Jaw Crusher Parts: Movable and fixed jaw plate, side plate, eccentric shaft, toggle plate, bearing, and support seat.

- Impact Crusher Parts: Blow bars, impact plates, breaker plates, side liners, rotor.

Grinding Mill Parts: Head linings, shell linings, discharge parts, trunnion linings, grinding media(ball mill balls), etc.,

Slurry Pumps Parts: Impeller, throat bush, liners, frame plate liner insert, casing, etc.,

Hydrocyclone Parts: Hydrocyclone liners

Other Parts & OEM Parts: Conveyor Belts and other OEM parts.