This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > Aggregates Processing Plant

Jiangxi Shicheng Mine Machinery Factory(JXSC) has over 35 years of experience in the design, manufacture, installation, and aftersales support of turn-key Crushing and Screening equipment. We specialize in providing comprehensive solutions and equipment for aggregate production and processing.

JXSC Aggregates Service

Aggregate Processing Plant

Aggregate is the stone material used to construct buildings, roads, and other infrastructure. It is one of the main components of engineering materials such as concrete, asphalt concrete (also known as hot-mix asphalt), railway ballast, and roadbed. Aggregate is obtained from natural ore through crushing, screening, and washing. Common aggregate types include Coarse Aggregate (particle size>5mm), Sand (0.06mm<particle size<5mm), Gravel (5mm<particle size<20mm), and Slag.

Aggregate Processing Plant Process

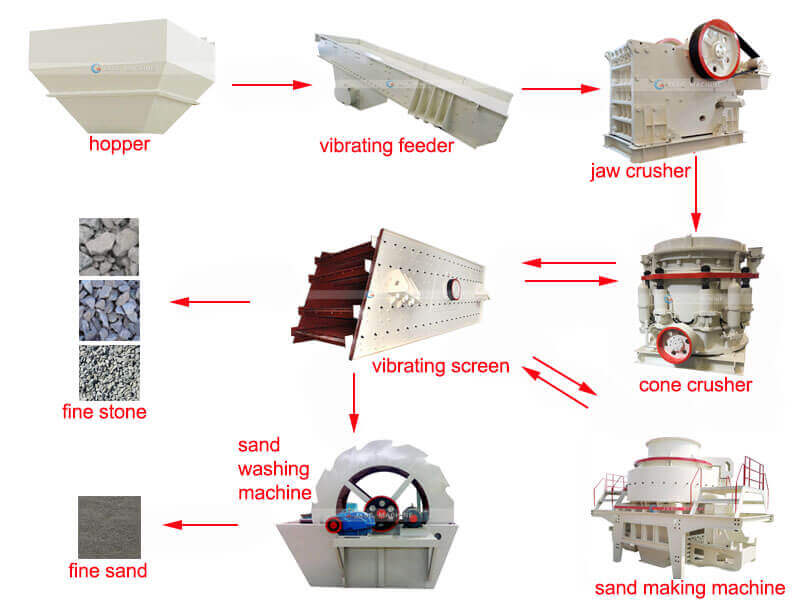

Aggregate processing plants include feeding systems, crushing sand systems, screening & sorting systems, and sand washing systems.

1. Feeding System

The raw materials and processed aggregates are conveyed during the processing to ensure the continuity of the production line. Conveying equipment includes conveyor belts, bucket elevators screw conveyors, vibrating feeders, etc. A vibrating feeder is commonly used to deliver raw materials to the crushers and vibrating screening equipment in the gravel aggregate processing plant.

2. Crushing Sand System

The crushing system is the process of crushing the raw materials. Common crushing equipment includes jaw crushers, impact crushers, cone crushers, hammer crushers, sand-making machines, etc. The jaw crusher is used for primary crushing. The sand-making machine is used to crush and shape the materials finely

3. Screening & Sorting System

Screen the crushed stones and sands to different particle size grades according to the needs. The common screening equipment includes vibrating screens, rotary vibrating screens, and drum screens.

4. Sand Washing System

The sand washing system removes impurities and soil in the stone to improve the aggregate quality. Sand washing equipment usually includes sand washing machines and dehydrators.

Applicable Materials for Aggregate Processing Plants