Three Disc Dry Magnetic Separator

【Capacity】100-500 Kg/H

【Feeding Size】≤2mm

【Type】3PC-500, 3PC-600, final process of heavy mineral concentrate, improve the grade.

【Application】Dry magnetic separations of ilmenite, rare earth ore, chromite, tungsten and tin ores, limonite, columbium and tantalum ores, zircon, rutile, monazite, andalusite, garnet, kyanite, feldspar, quartz and other minerals with magnetic differences or removal of iron in nonmetallic minerals.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

Three Disc Dry Magnetic Separator applicable to dry separation of titanium, rare earth ore, tungsten-tin ore, chromite, niobium-tantalum ore, Limonite, Zircon, gold red, solitary, feldspar, quartz, and other magnetic differences in a variety of metallic minerals or non-metallic materials of the iron remover, but also magnetic and non-magnetic minerals separation purification.

【Application of Magnetic Separation】3pc disc magnetic separator separates weak minerals and rare metal ore. It is a very important mineral processing equipment. Three-disc magnetic separators are divided into two types of dry three-disc high-intensity magnetic separators. The magnetic field intensity can be obtained by adjusting the magnetic field current of the magnetic disks to form different intensities to separate the minerals efficiently, and by adjusting the induction distance between the magnetic disks and the selected particles to achieve one-time separation of various minerals. This equipment is widely used in the dry separation of Ilmenite, monazite, tungsten tin ore, tantalite, and other magnetic and non-magnetic minerals.

【Feature】Magnetic separator for grinding machine equipment structure is reasonable, covers an area of small, simple operation and maintenance, and can be a one-time separation of strong magnetic, weakly magnetic, non-magnetic, and other minerals. It can be applied to dry mining in the water-deficient mining area.

JXSC, a professional magnetic separator supplier, supplies types of magnetic separators, including Dry Drum Magnetic Separator, Wet magnetic separator, Roller Electrostatic Separator, Three-disc dry magnetic separator, High-Intensity Magnetic Separator, magnetic separator laboratory use equipment. Magnetic separator design service is available.

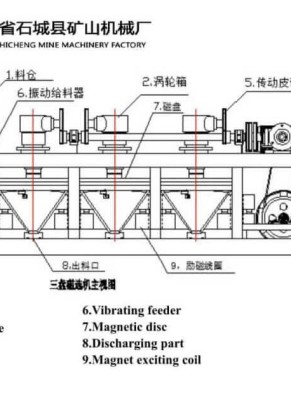

Product Structure

【Magnetic Separator Working Principle】Disc magnetic separator is mainly used for separating 0.05 ~ 3 MM grade magnetic minerals. On the basis of the feasibility of magnetic separation, through the design of double-roll type, the magnetic roller with strong magnetism is used to directly select the first and second-grade magnetic minerals Significantly increased mineral recovery. The permanent magnet system design ensures stable operation and high concentrate grade. The complete machine structure is simple, the transmission part uses the outside naked type, has realized in the production process the rapid maintenance and the overhaul. Three magnetic separators transmission principle is also very simple, easy to operate, but also very high efficiency. Three magnetic separators into a higher electrical control technology, so that easy to understand production operations, improve work efficiency and reduce the operator's labor intensity. There is an adjustable separator in the separator, the separator is made of stainless steel, which can guarantee the service life of the separator effectively and avoid the possibility of rust affecting the mineral quality; the separator can be adjusted flexibly and fixed quickly It plays an important role in ensuring the quality of ore grade in the production process.

Technical Parameters

| Model | 3PC-500 | 3PC-600 |

| Magnetic Intensity(Gauss) | 0-18000 | 0-20000 |

| Number of Magnetic Disks (Pieces) | 3 | 3 |

| Revolution of Magnetic Disk(r/min) | 25-40 | 22-38 |

| Power Supply(V) | 380 | 380 |

| Exciting Coil(Unit) | 4 | 4 |

| Matching Motor(kW) | 0.75 | 1.5 |

| Exciting Power(kW) | 1.5 | 1.6 |

| Feed Size(mm) | ≤2 | ≤2 |

| Capacity(Kg/H) | 100-300 | 200-500 |

| Overall Size(mm) | 2800×800×1220 | 3200×870×1160 |

| Weight(kg) | 1900 | 2200 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.