Raymond Grinding Mill

【Capacity】 1-25 T/H

【Max Feeding Size】 <40mm

【Discharge Size】0.045-0.6mm

【Materials】The material below scale 6 of Mohs hardness and 250-odd sorts of non-inflammable and non-explosive stuff for high fine powder generation and processing, such as talcum, barite, marble, limestone, and charcoal blacks.

【Application】Mining, metallurgical industrial, chemical engineering, building material, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

【Raymond Grinding Mill Machine】 It is mainly suitable for the processing of materials in the building materials, chemical industry, metallurgy, mining, abrasives, refractory materials, ceramics, iron and steel, electric power, coal, and other industries. It can grind quartz stone, barite, fluorite, rare earth, marble, ceramics, iron ore, copper ore, phosphate rock, slag, water slag, cement clinker, activated carbon, dolomite, granite, coking coal, lignite, diamond Beautiful sand, chrome oxide green, gold ore, red mud, clay, kaolin, coke, coal gangue, china clay, fluorspar, bentonite, diabase, pyrophyllite, phyllite, basalt, gypsum, graphite, silicon carbide, thermal insulation materials Various non-flammable and non-explosive mineral materials with Mohs hardness below 9 and humidity below 6%.

【Features】

- Mineral materials with a Mohs hardness of less than 9.3 can be processed and crushed.

- The finished product has a wide range of particle sizes. The coarsest particle size can reach 0.95 mm (20 mesh), the fine powder particle size can generally reach 0.038 mm (400 mesh), and the finest part of the material can reach 0.013 mm (1000 mesh).

- The dust removal effect fully meets the national dust emission standard.

- The analysis machine is easy to adjust.

- The grinding device adopts overlapping multi-stage sealing with good sealing performance.

【Raymond Mill Working Principle】

1. The working process of the whole mill: After the bulk material is crushed to the required particle size by the jaw crusher, the material is sent to the storage hopper by elevator, and then the material is continuously fed evenly and quantitatively through the vibrating feeder Grinding in the main machine grinding chamber, the ground powder is taken away by the airflow of the fan, and classified by the analyzer. The fineness of the powder enters the large cyclone collector through the pipe with the airflow for separation and collection, and then the powder is discharged The valve discharge is the finished powder. The airflow is sucked into the blower by the return duct at the upper end of the large cyclone collector. The entire airflow system of this machine is closed and circulating, and it circulates under positive and negative pressure.

2. Because there is a certain amount of water in the material to be ground in the grinding chamber, the heat generated during grinding causes the gas in the grinding chamber to evaporate and change the airflow. The residual air pipe balances the airflow, and the excess gas is introduced into the bag filter. The fine powder brought in by the residual gas is collected, and the residual gas is purified and discharged.

3. The working process of the main machine is to drive the central shaft to rotate through the transmission device. The upper end of the shaft is connected to a plum blossom frame. The frame has a grinding roller device and forms a swing fulcrum. It not only revolves around the center but also the grinding roller revolves around the grinding ring. The grinding roller itself rotates due to friction. The lower end of the plum blossom frame is equipped with a shoveling system, which is located at the lower end of the grinding roller. During the same rotation of the shovel and the grinding roller, the material is shoveled and fed between the rings of the grinding roller to form a cushion layer, which is produced by the rotation of the grinding roller The outward centrifugal force (i.e. squeezing force) crushes the material, which achieves the purpose of milling.

4. The analyzer drives the blades on the turntable to rotate through the speed-regulating motor to form a classification effect on the powder. The blade speed is adjusted according to the size of the finished powder. When you want to obtain the finer-grained powder, you must increase the blade speed to increase the contact between the blade and the powder, so that the blade throws the undesirable powder. The outer wall is separated from the airflow, and the coarse powder falls into the grinding chamber for regrinding due to its gravity. The qualified finished powder is sucked into the cyclone collector with the airflow through the blades. After the airflow and the powder are separated, the powder is collected.

5. The large cyclone collector plays an important role in the performance of the mill. When the airflow with powder enters the collector, it rotates at a high speed. After the airflow is separated from the powder, the gas fluid wall shrinks to the center and moves to the bottom of the cone. (The natural length of the airflow) forms a rotating upward airflow cylinder, and the powder is separated and collected. Since the core of the upwardly rotating airflow is in a negative pressure state, the lower end of the collector must be tightly sealed, and the outside air must be strictly separated, otherwise, the collected powder will be taken away by the core airflow again, which directly affects the overall performance of the machine. Therefore, the lower end of the collector is equipped with a closed-air discharger.

Product Structure

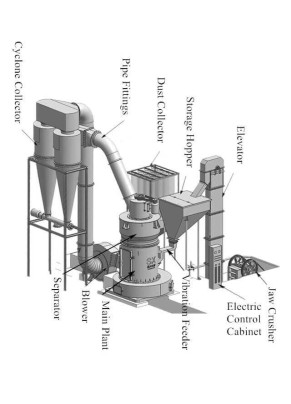

【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc.,

Structural Features

- The whole mill is of spatial structure, less premise and systemic strong. The whole system from roughing, transportation, powder collecting to packaging forms an independent production system.

- Even granularity, sieving rate 99%, which is unapproachable for other mills.

- The driving device applies an enclosed gearbox and belt pulley, so the transmission is calm and the operation is reliable.

- All the main parts of Raymond Mill adopt high-quality steel, the resistant parts use high-performance proof materials, so the whole system has high wear resistance and reliable performance. The blade frame of the main machine keeps in touch with the materials, it consists of the upper part and lower part, when the lower part is worn down, just take down the bolts to exchange it.

- Centralized controlling of the electrical system, unmanned operation, easy maintenance.

- Less dust pollution, low noise.

- Adopting an electro-vibrating feeder, it can feed evenly and is easy to adjust, features miniature size, lightweight, power-saving, and easy maintenance.

Technical Parameters

| Model | Roller | Ring | Feeding Size (mm) | Finished Size (mm) | Motor Powder (kw) | Capacity (t/h) | Overall Dimension (mm) | |||

| Quantity (piece) | Diameter (mm) | Height (mm) | Inner Diameter (mm) | Height (mm) | ||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 18.5 | 1–3 | 4300*3500*5100 |

| YGM8314 | 3 | 270 | 140 | 830 | 140 | 20 | 0.613-0.033 | 22 | 1.2–4.6 | 5300*4100*5200 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 37 | 2.1-5.6 | 7100*5900*7900 |

| YGM4121 | 5 | 410 | 210 | 1280 | 210 | 30 | 0.613-0.033 | 75 | 2.8-10.5 | 9200*7250*9700 |

| MTM160 | 6 | 440 | 270 | 160 | 270 | 35 | 0.613-0.033 | 132 | 5–20 | 12550*5700*8350 |

【YGM7815 Introduction】

Raymond Mill Equipment Parameters of YGM7815: 1. Jaw crusher 2. Jaw crusher motor 3. Hoist 4. Bucket elevator 5. Feeder 6. Hopper 7. Powder separator motor 8. Powder separator 9. Main machine 10. Main machine motor 11. Cyclone set Powder device 12. Powder separator motor seat 13. Reducer 14. Dust remover 15. Blowing system 16. Fan motor 17. Electric control cabinet

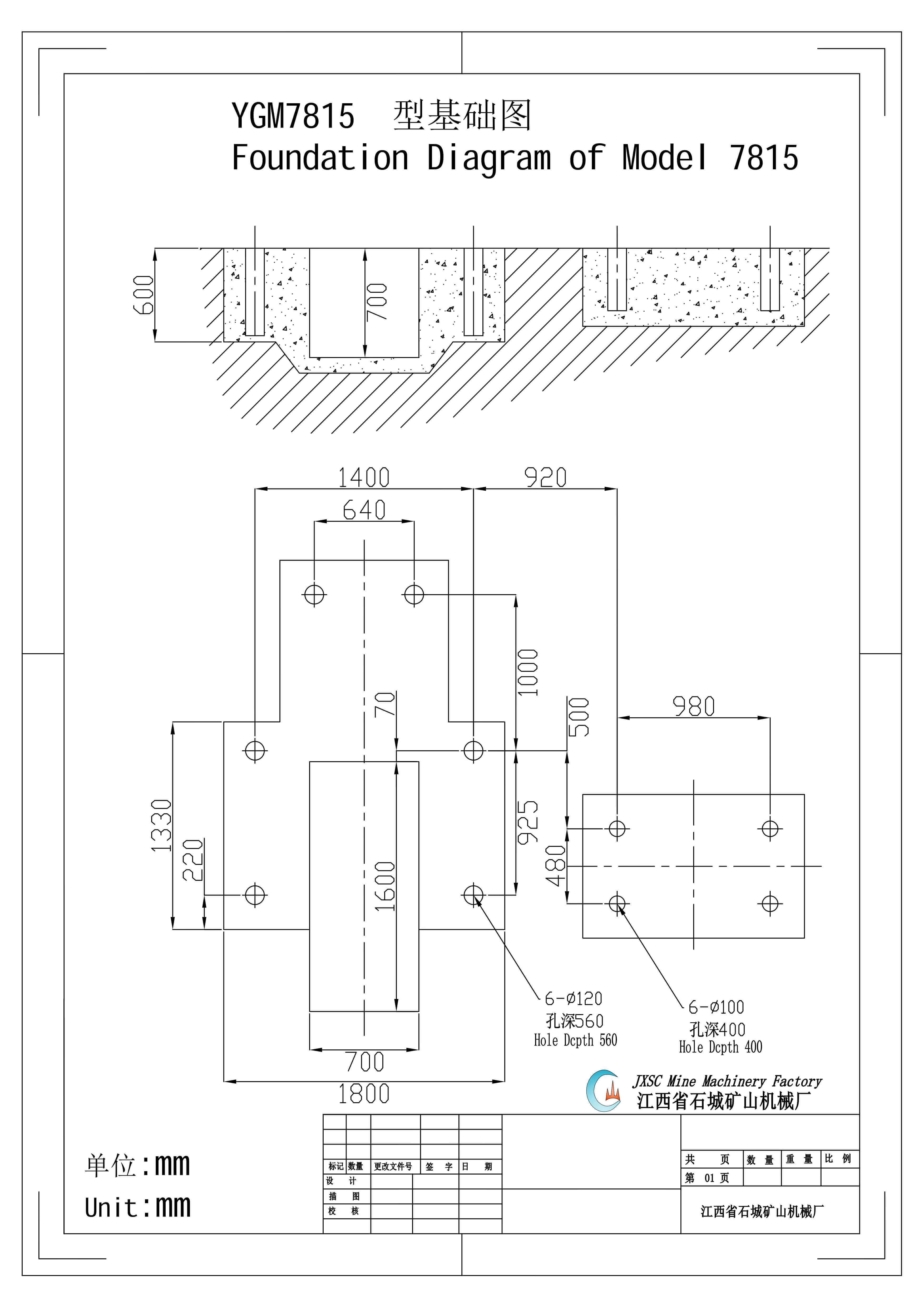

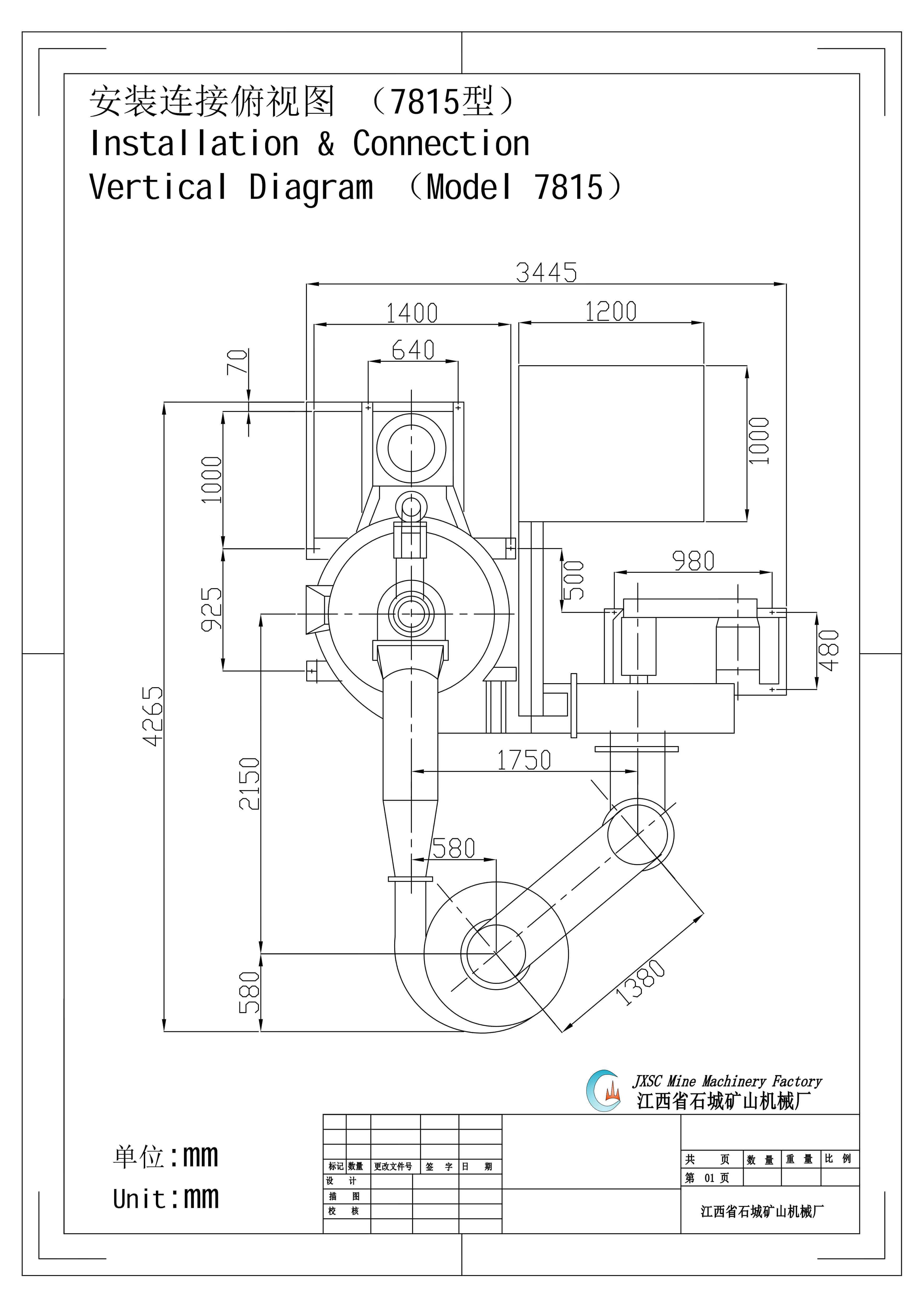

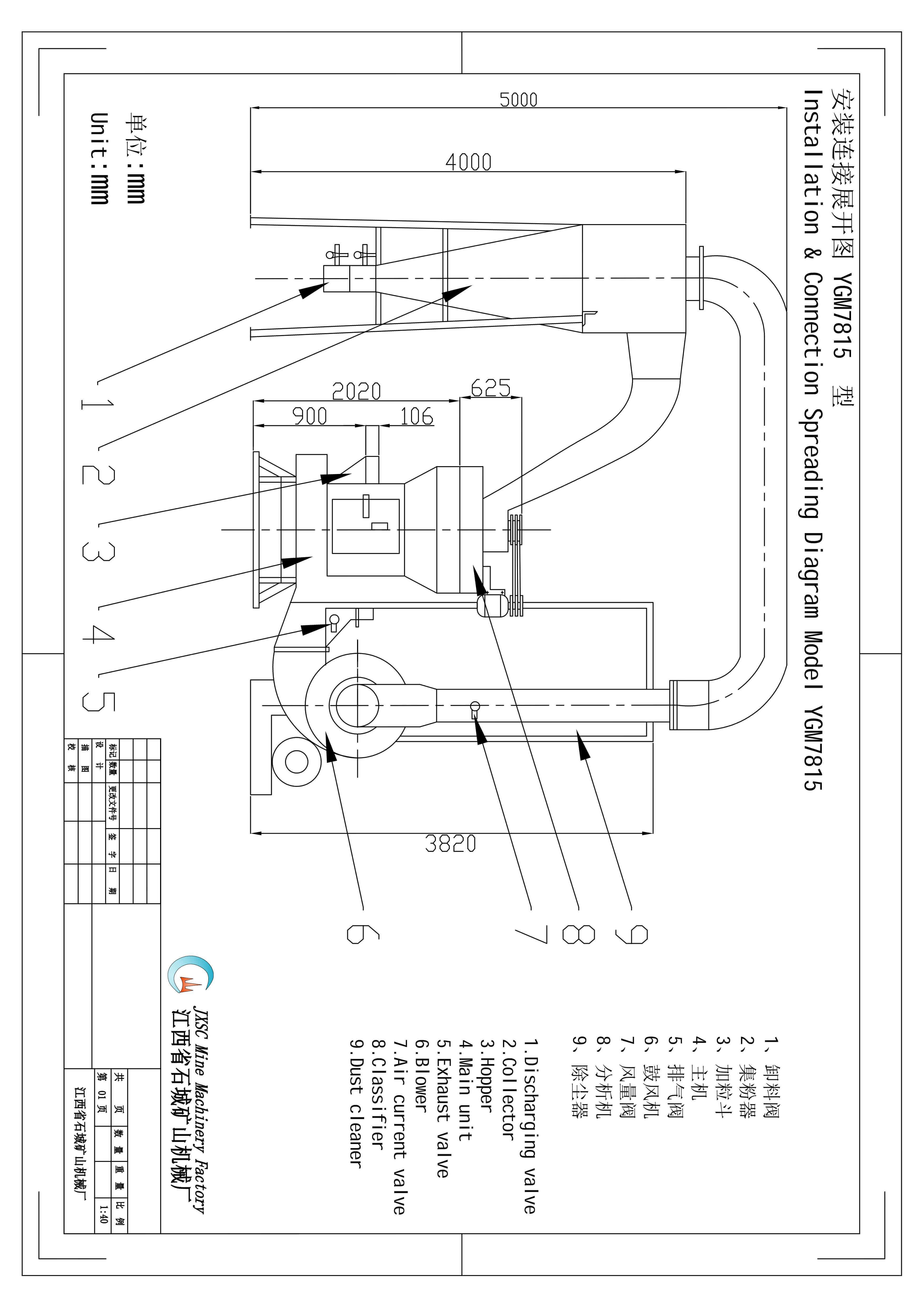

Raymond Mill Model YGM7815 Diagram

| YGM7815 foundation diagram | YGM7815 installation connection vertical diagram | YGM7815 installation and connection spreading diagram |

|  |  |

【Raymond Mills Manufacturer】JXSC mine machinery is a professional Raymond grinding mill machine manufacturer in China. It designs Raymond mill plants for gold, coal, limestone, barite, and other mining ores. The Ramond mill grinder is for sale at factory price. It also supplies Raymond mill pulverizer for lab use. Welcome to contact to get the details.

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.