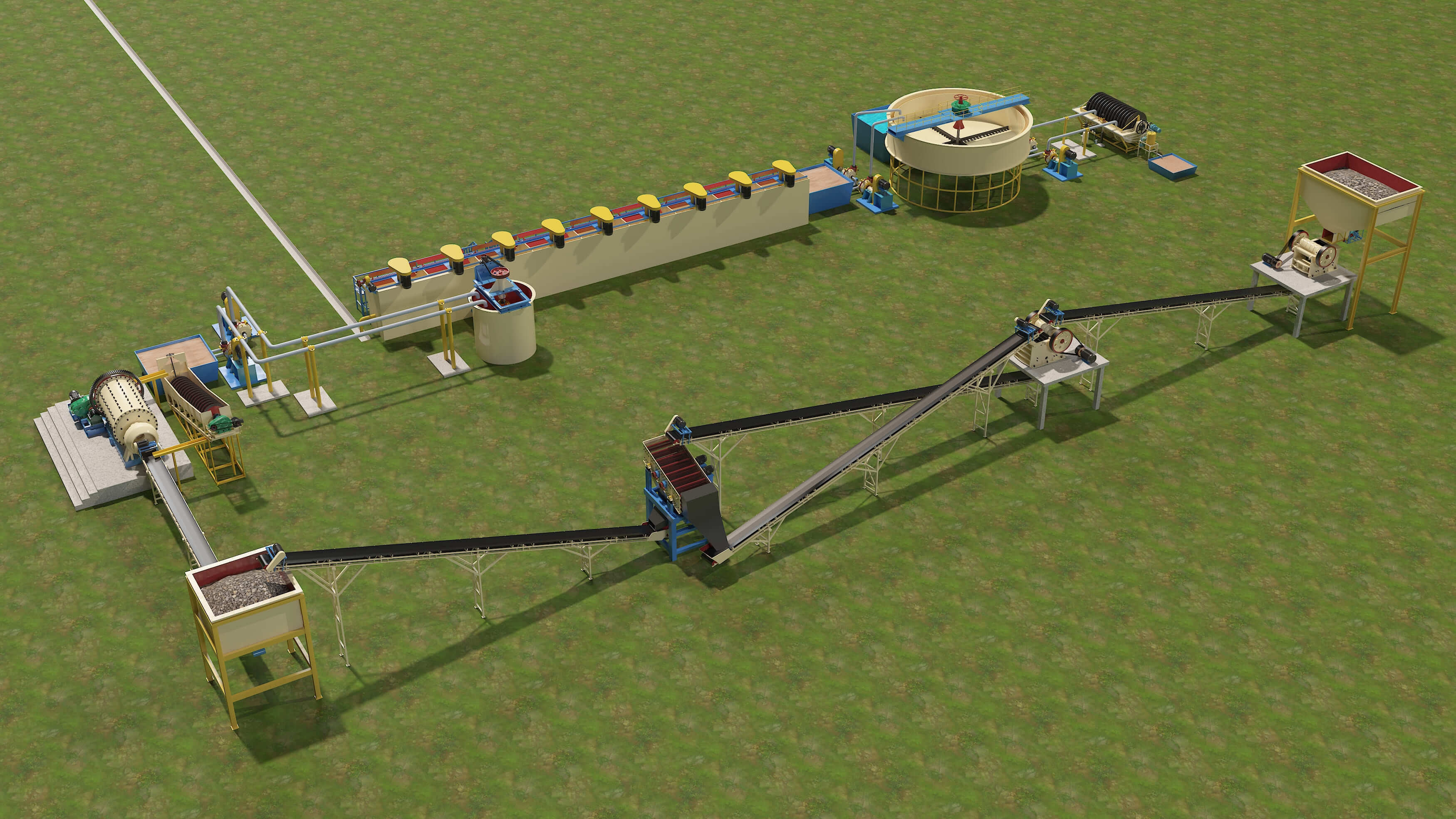

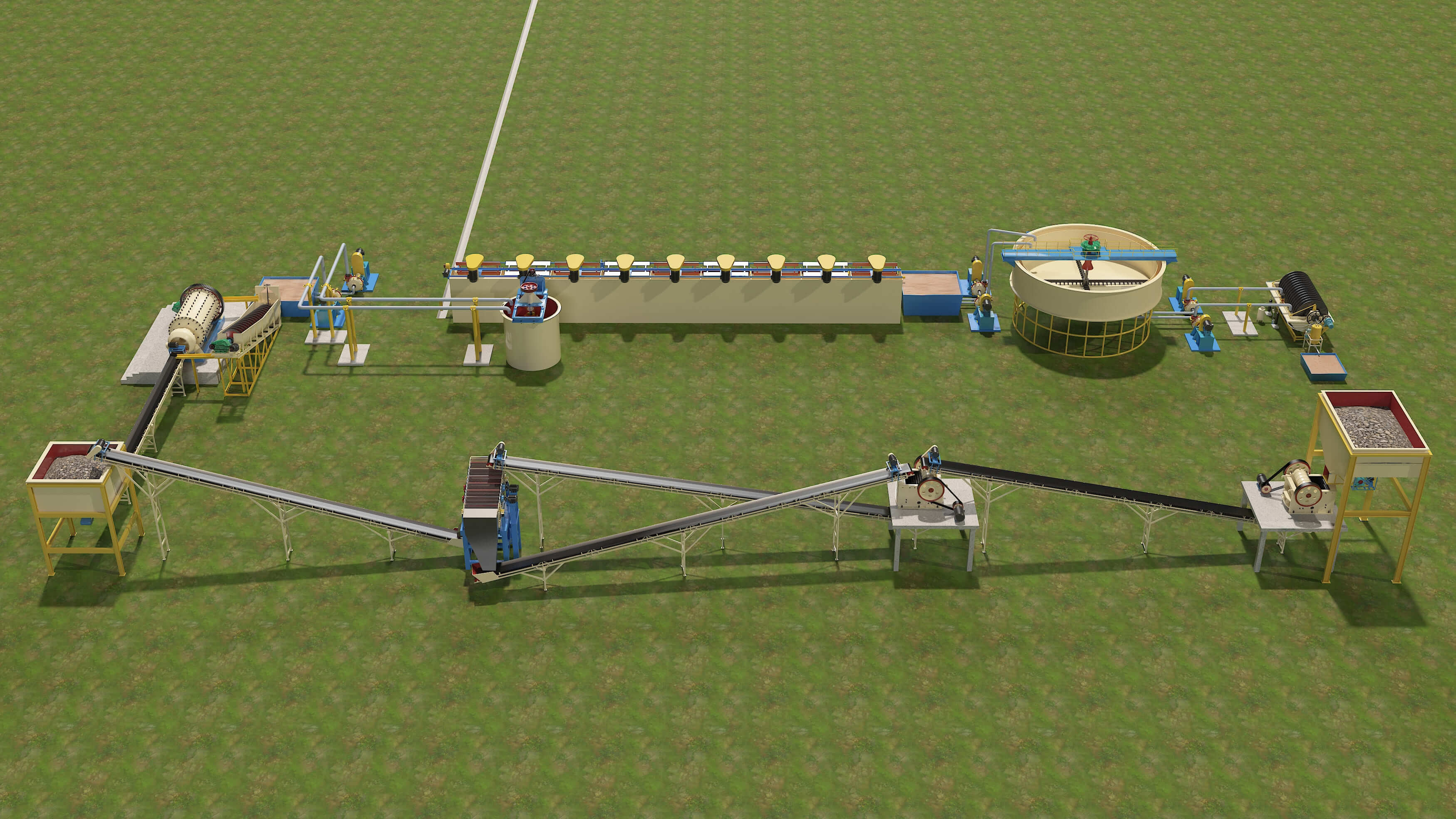

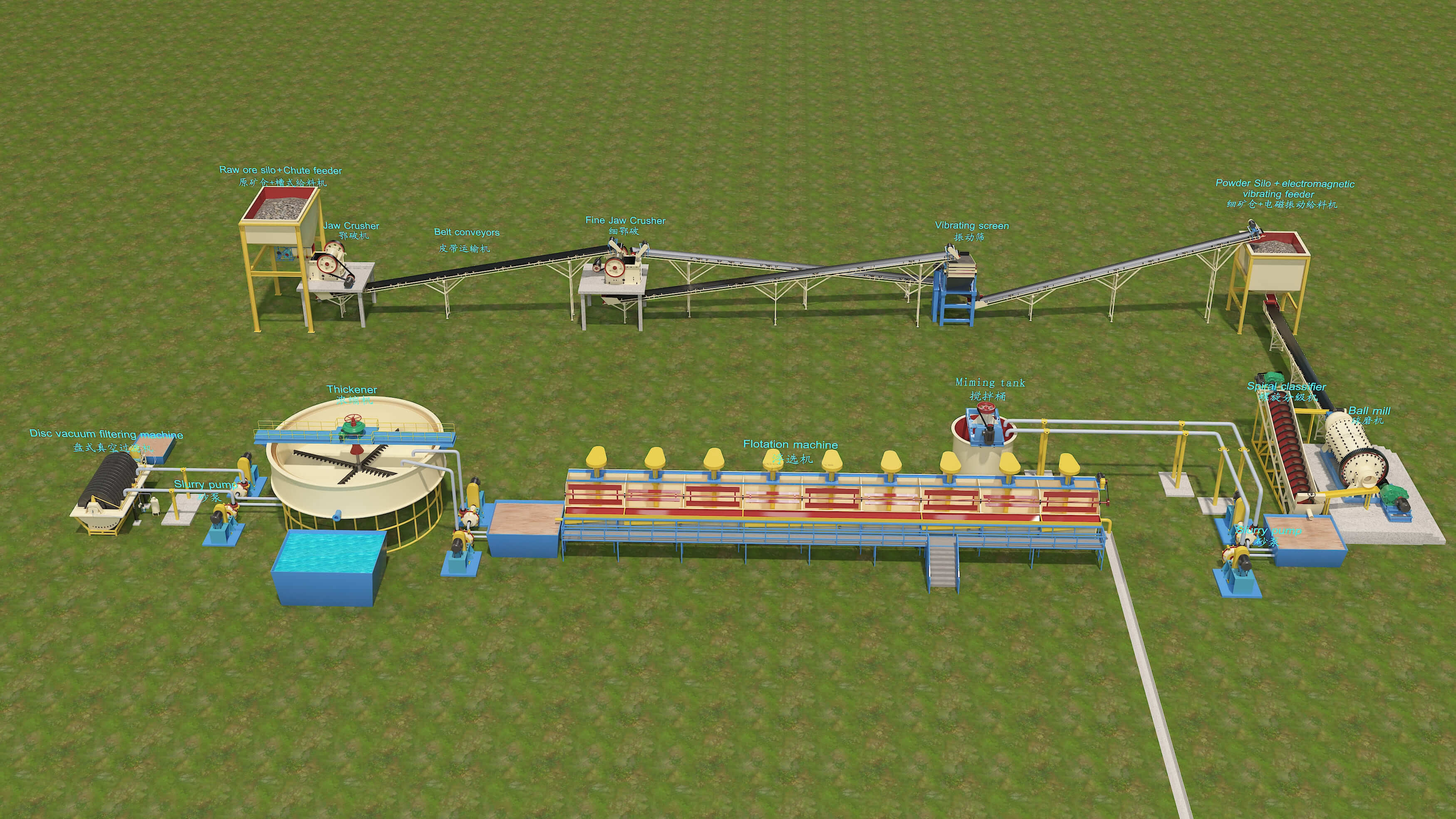

The full sulfide rock minerals processing plant includes 4 systems.

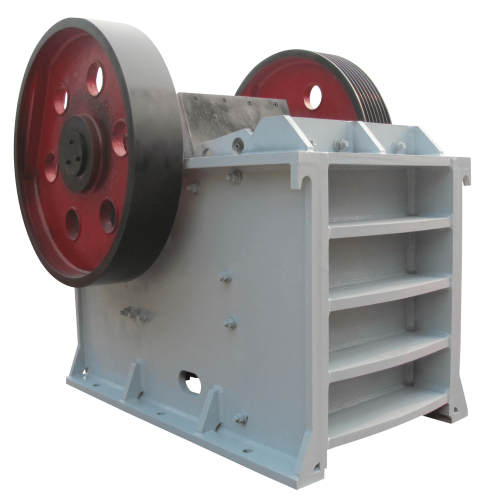

1. Crushing System

Chute feeder is for feeding raw material to primary jaw crusher stably and evenly, can feed 0-300mm stones, if bigger size and capacity, can use grizzly vibration feeder. Then primary jaw crusher crushes the big rock to a smaller size, about 0-80mm. The output sends to a fine jaw crusher to crush again to below 25mm particles. But there still have some +25mm particles, so better send to vibration screen to sieving out 0-25mm go to ball mill grinding system. and +25mm go back to fine crushing again.

The feeding size of the ball mill can be smaller, the smaller, the better, grinding efficiency will much higher. So sometimes, will have 3 stages crushers in the crushing system to make a smaller feeding size for the ball mill (0-5mm or 0-8mm or 0-10mm).

2. Grinding System

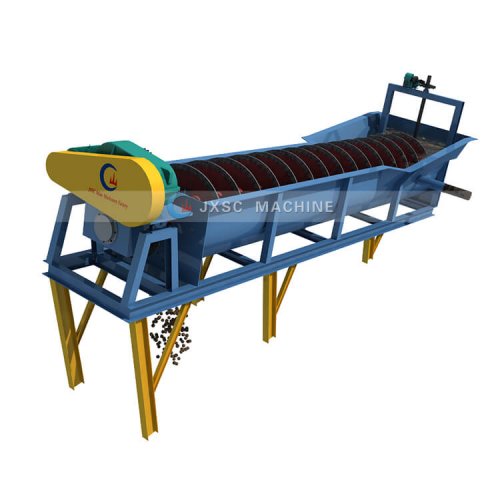

The 0-25mm material will firstly go to a storage bin before feeding to the ball mill, so the crushing system can work separated from the grinding system as long as has stock enough 0-25mm in a storage bin. Then feed the 0-25mm material by swing feeder or electromagnetic vibration feeder to ball mill through belt conveyor. The ball mill is for grinding material to small fine powder because flotation process needs 200mesh material, need work together with a spiral classifier to reach 200mesh output from the overflow of classifier, the underflow coarse particles will go back to ball mill grind again, to be closed-circuit. So from this grinding system will get 200mesh slurry.

3. Flotation System

The 200mesh slurry will be firstly sent to mixing tank by slurry pump, to make sure material is mixed completely, then from mixing tank go to flotation machines, need to add different chemicals in flotation machine to separate out different minerals, the flotation process has the primary selection, secondary selection, and final selection, this is for increase minerals grade to maximum after the process. If need a higher grade, then need to flotation more times. Will get each mineral concentrate ore after flotation system.

4. Concentrate ore filtering system

After getting the minerals to concentrate ore from the flotation system, for the high-grade minerals, such as copper, Zinc, Lead, Fluorite, use the thickener to concentrate, make higher density, then send to disc vacuum filter machine to filter water, and get more dry concentrate minerals. Then can dry in the sun or by drying machine to get complete dry minerals to concentrate ore.

This Sulfide Rock Minerals Flotation processing plant is highly effective in recovering sulfide minerals, the plant design can be customized as per rock minerals conditions, capacity can be small, medium, and big as per request.