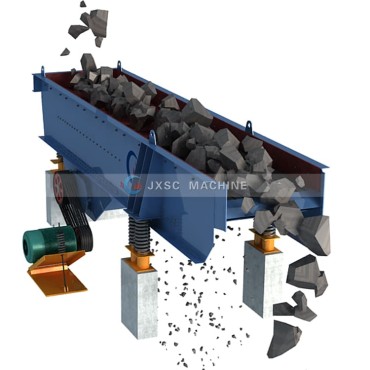

Vibratory Feeder

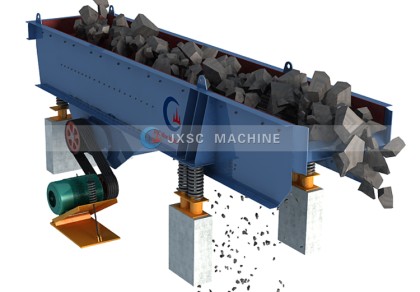

JXSC’s Vibrating Feeder is an instrument that uses vibration to “feed” material to a process or machine. Our vibratory feeders use vibration and gravity to move material: Gravity determines the direction, either down or down and to a side, and then vibration is used to move the material.

[Capacity] 96-1200 T/H

[Processible Material] Ore, coal, aggregate, concrete, artificial sand, quartz sand, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The Vibratory Feeder is a kind of advanced industrial feeder. Compared with other material feeders, it has the following characteristics:

- Small volume, lightweight, simple structure

- Easy installation and maintenance, low running cost

- High efficiency and large feeding capacity

- Low Noise, good for improving the working environment

- Less power consumption, high power factor

- Adding ingredients, the feeding quantity can be adjusted conveniently and steplessly by adjusting the eccentric block.

JXSC provides tailor-made mining equipment solutions in metallurgy, coal mines, mineral dressing, building materials, the chemical industry, abrasives, and so on, from individual equipment to the whole production line.

JXSC vibratory feeder is perfectly used to evenly give bulk and granular materials from the storage bin, timing, and continuing to the receiving device. The crushing machinery can be fed continuously and uniformly in the sand and stone production line.

We are an original Chinese mineral equipment producer offering vibrating feeder designs to meet your demand, grizzly feeders, electromagnetic vibrating feeders, trough feeders, and apron feeders.

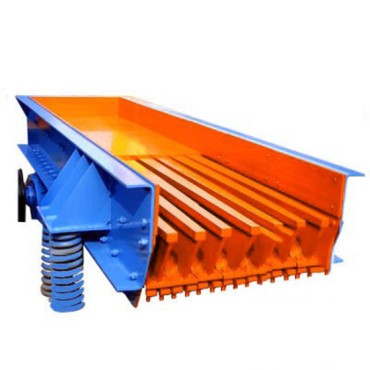

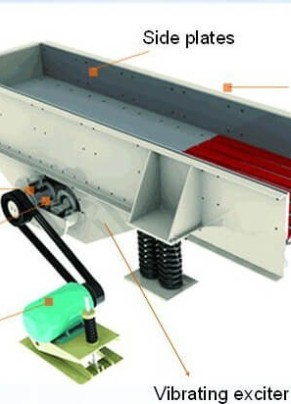

Product Structure

The vibratory feeder is widely used in industry feed to the crusher, sorting machinery, screening equipment, transport machinery, and packaging machinery.

Designed for uniform conveying of bulk materials before coarse crusher in crushing and screening. The vibration feeder adopts a double eccentric shaft vibration exciter to ensure the equipment can bear the impact of falling pieces of material, and the feeding capacity is large. In the production process, block and granular materials can be uniform, regularly, and continuously transferred from the silo to the feeding device, thus preventing the feeding device from dying due to uneven feeding and prolonging the service life of the equipment. The feeder can be divided into steel plate and grating structures. The Steel Plate Structure Feeder is mostly used in sand and stone production. The material can be uniformly fed into the crushing equipment. The Grate Structure Feeder can coarse screen the material, makes the system more economical and reasonable, and has been used as essential equipment in crushing and screening.

Technical Parameters

| Vibrating Feeder Parameter | ||||||

| Model | Size of Funnel(mm) | Max Feeding Size(mm) | Feeding Capacity(t/h) | Motor Power(kW) | Dimensions(mm) | |

| DN380*95 | 3800×950 | 500 | 96-160 | 11 | 3882*2224*2121 | |

| DN490*95 | 4900×950 | 500 | 120-240 | 15 | 4957*2277*2150 | |

| DN490*110 | 4900×1100 | 580 | 120-280 | 15 | 4957*2400*2150 | |

| DN590*110 | 5900×1100 | 600 | 200-350 | 22 | 6000*2500*2150 | |

| DN600*130 | 6000×1300 | 750 | 400-560 | 22 | 6082*2580*2083 | |

| DN600*150 | 6000×1500 | 1000 | 800 | 30 | 6627*2350*3068 | |

| DN600*200 | 6000×2000 | 1000 | 1200 | 37 | 6436*3853*3014 | |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.