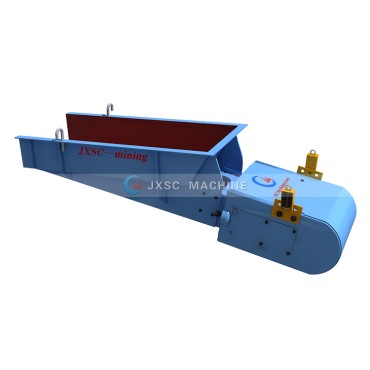

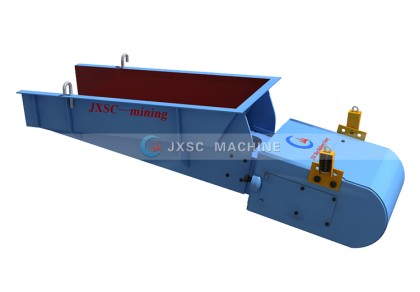

Electromagnetic Vibrating Feeder

【Capacity】 5-150 T/H

【Feeding Size】 50-200 mm

【Processible Material】Gold,chrome,tin,coltan,diamond ,tantalite ,silica sand, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The electromagnetic vibrating feeder is a new feeding equipment widely used in mining, metallurgy, coal, building materials, chemical industry, electric power, grain, etc. Uniformly, continuously or quantitatively feeding bulk, granular, and powder materials from silos or other storage equipment to receiving equipment for automatic batching, quantitative packaging, and automatic control. The utility model has the advantages of small volume, low noise, lightweight, less power consumption, convenient installation and maintenance, etc.

1. Exclusive vibrating technology.

2. Small size and light in weight.

3. Simple structure, easy to install and use, low maintenance cost.

4. High efficiency and feeding capacity, high working frequency, and low electric consumption

5. Good operational reliability and easy adjustment

6.No pollution.

For example, to the conveyor belt, screening equipment, and other feed to the crusher equipment, crusher and feeding, as well as for automatic batching and quantitative packaging, and can be used in the automatic control of the process to achieve the production process automation.

Product Structure

【Vibrating Feeder Working Principle】Electromagnetic vibrating feeder manufacturer is mainly used to evenly and continuously feed materials to the conveyor belt, bucket elevator, crusher, ball mill, etc. It can also be adopted to realize the automatic production process. This machine is not suitable for conveying wet and sticky materials.

During the use of the electromagnetic feeder, the exciting force can be adjusted to change and control the flow rate, so the adjustment is convenient, the flow rate is stable, the noise is low, the power consumption is small, there is no punching phenomenon, and the machine has the characteristics of lightweight, small volume, convenient maintenance, etc. If the closed structure is adopted, dust overflow and environmental pollution can be prevented.

Technical Parameters

| Model | Discharge Chute Size L*W*H(mm) | Max Feeding Size (mm) | Capability (t/h) | Voltage(V) | Motor Power (kW) | Weight(kg) | Overall Dimensions L*W*H (mm) |

| GZ1 | 600*200*100 | 50 | 5-10 | 220 | 0.06 | 80 | 910*376*485 |

| GZ2 | 800*300*120 | 50 | 10-20 | 220 | 0.15 | 165.5 | 1175*608*600 |

| GZ3 | 900*400*150 | 75 | 20-30 | 220 | 0.2 | 223 | 1325*578*675 |

| GZ4 | 1100*500*200 | 100 | 30-50 | 220 | 0.45 | 462 | 1616*762*814 |

| GZ5 | 1200*700*250 | 150 | 50-100 | 220 | 0.65 | 656 | 1815*840*980 |

| GZ6 | 1600*900*250 | 200 | 100-150 | 380 | 1.5 | 1252 | 2410*1092*1500 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.