This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > Spare Parts > Grinding Mill Parts

Grinding Mill Parts/Components

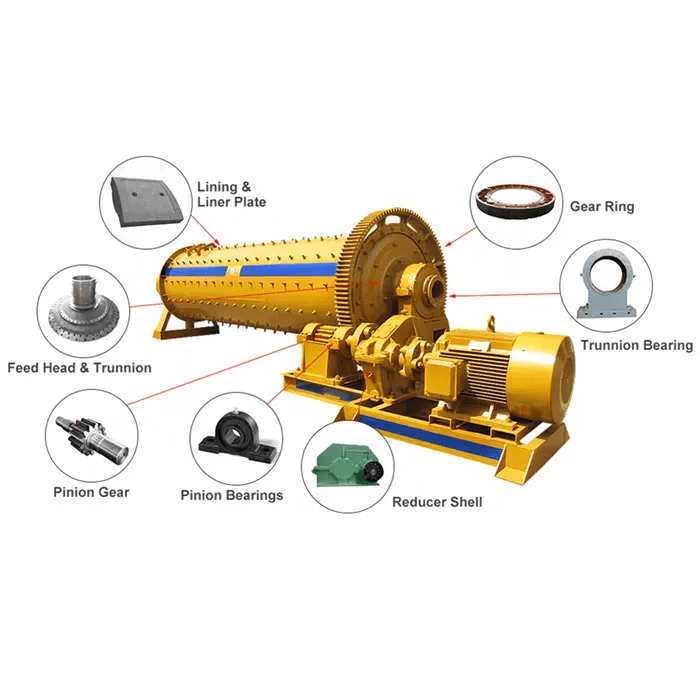

The typical grinding mill includes the ball mill, rod mill, SAG mill, Raymond grinding mill, AG mill, vertical mill, etc., Due to the work impact, the quality of the grinding mill parts and components directly determines the service life of the grinder.

JXSC Machine mainly supplies customized mill parts and components that aim to improve the reliability of your machine. We not only manufacture ball mills, rod mills, and Raymond mills but also provide grinding mill components compatible with many grinding mill brands.

The grinding mill components: Rubber or Composite mill liners, spare parts such as trommel screens, and grinding media.

The Grinding Mill Parts We Supply

Our Grinding Mill Liners

The excellent quality mill liners maximize uptime and service interval while providing improved ore crushing. Our grinding mill liners are low-noise, low-weight, high-strength designs, excellent sealing, and so on.

Head Liners

Material: Rubber

Thickness: Customized

Application: AG Mill, Ball Mill, Rod Mill, Batch Mill, etc.,

The headliner is an important part of the ball mill, and it’s called the “feed end liner for the ball mill’, which protects the end cover of the ball mill. The high wear-resistance headliner provided by us has improved the wear condition of the feed end liners for the ball mill, which make the end liners have good wear-resistance and effectively increases the service life.

Shell Linings

The shell liners protect the inner shell of the cylinder from being impacted and worn directly by material and grinding balls.

Advantages of Shell Mill Liners

- The optimum lifting action of the balls.

- Optimum expansion of the ball charge.

- Minimize the dead zone of the ball charge.

- Significant reduction of the wear rates of the ball and the liners.

- Minimum operating cost due to longer lifetime and no breakage of the liner plates.

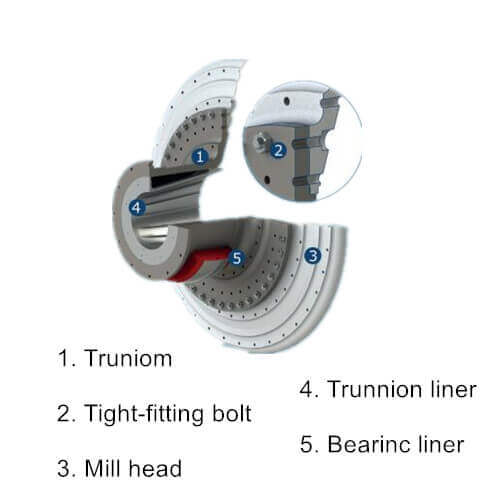

Trunnions Liners

The trunnion liner fits inside the bearing to protect it from wear caused by the ore being washed over the liner and through the bearing as it is fed to or discharged from the mill. They are manufactured with a fabricated steel base that is then rubber lined. Loose steel-reinforced rubber liners are also used in larger trunnions.

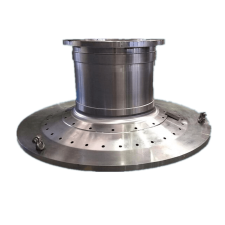

Trunnions

Material: ASTM: 1025/ DIN: CK25/ BS: 070M26

Diameter: >2 meters

Weights: 1 -12 tons

Application: Ball mill, SAG mill, AG mill, Rod mill, coal mills, cement mills, etc.

Mill trunnion is a special type of steel casting, which is an important part of the ball mill, SAG mill, Rod mill, and cement mill. It supports and connects the ball mill cylinder and is also a passage for raw materials.

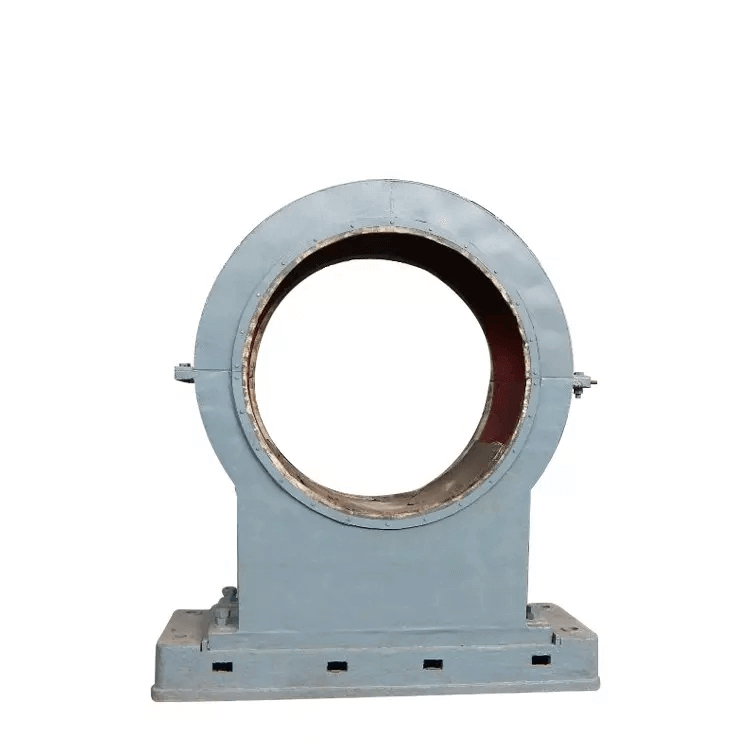

Main Bearings

The main bearing is a critical component in the ball mill, and its function is to support the entire rotating part of the ball mill. In addition to bearing the total weight of the ball mill cylinder, grinding body, and materials, it also holds the impact load caused by the movement of grinding bodies and materials. Therefore, there are high requirements for the main bearing’s reliability, life, maintenance, and energy consumption.

There are two types of bearings: one is a sliding bearing, and the other is a rolling bearing.

Sliding bearing

Sliding bearings can divide into ordinary sliding bearings, dynamic pressure oil film bearings, and hydrostatic oil film bearings. Ordinary bearings are generally used in small and medium mills, and oil film bearings are only used in large mills.

Rolling bearing

The rolling bearing ball mill has a remarkable energy-saving effect.

The selection and performance of the main bearing directly determine the ball mill’s overall operation and affect the ball mill’s operating rate, energy consumption, and production capacity.

Grinding Media

Ball mill grinding media and milling media are used in milling or grinding processes to crush, grind and mill various materials. Milling balls are made of steel is our most popular material for mining. JXSC Machine supplies quality, durable, and high-performance milling media.

Gears & Pinions

The gear is the transmission part of the ball mill. If it is damaged, the whole machine will stop. Therefore, the longer the service life of the gear, the better. When selecting the gear, the manufacturer should choose the gear with high wear resistance, impact resistance, and strength.

The pinion gear is the main component of electrically driven equipment. The motor drives the pinion to drive the host.

Trommel Screen

Trommel screens are also known as trommels or rotary screens. They are broadly applied in AG, SAG, and ball mills’ discharge ends to classify materials. They are a success in mineral processing plants of non-ferrous metals mines.

Our trommel screen features:

- High screening efficiency, less blockage.

- Simple structure, less space demanded, easy installation and maintenance, no designated driver or power source needed.

- It can select sieve holes in many shapes. Such as square holes, rectangular holes, long three-weft holes, round, triangle, equilateral triangle/grizzly holes, guide-track type, angled arrangement, loose rod arrangement, etc.,

Grinding Mill Parts

Grinding Mill Parts/Components OEM Brands

Note: We don’t cooperate with these brands. All parts we supply are manufactured and warranted by us and are not manufactured by or purchased from the Original Equipment Manufacturer.

OEM available for

- Polycorp AG/SAG Mill Liners

- Metso Ball Mill, AG/SAG Mill Liners

Why Choose Us?

Wear And Spare Parts for Sale

Crusher Parts

- Cone Crusher Parts: Bowl liners, concaves, mantles, feed cones, main frame liners, seat liners, distribution plates, lock nuts, and so on.

- Jaw Crusher Parts: Movable and fixed jaw plate, side plate, eccentric shaft, toggle plate, bearing, and support seat.

- Impact Crusher Parts: Blow bars, impact plates, breaker plates, side liners, rotor.

Grinding Mill Parts: Head linings, shell linings, discharge parts, trunnion linings, grinding media(ball mill balls), etc.,

Slurry Pumps Parts: Impeller, throat bush, liners, frame plate liner insert, casing, etc.,

Hydrocyclone Parts: Hydrocyclone liners

Other Parts & OEM Parts: Conveyor Belts and other OEM parts.