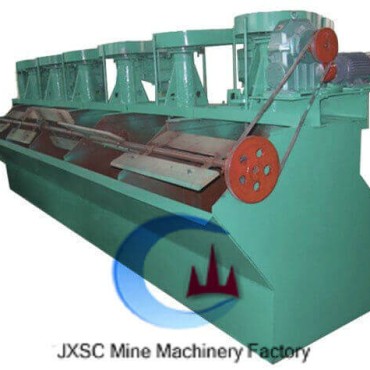

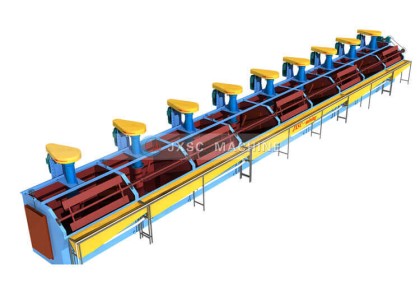

Flotation Machine

【Capacity】 0.18-20m³/min per cell

【Feeding size】 200 mesh no less than 80%

【Type】 Agitating flotation machine, Self-priming, aeration flotation, flotation column.

【Model】XJK, SF, GF, CHF, XJC, etc. Contact us for a specific & quick selection.

【Application】 Copper sulfide, gold sulfide, zinc, lead, nickel, antimony, fluorite, tungsten, and other non-ferrous metals, and also be used for coarse selection for ferrous metals and nonmetals.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

Flotation machine (floatation machine, planktonic concentrator) in the mineral processing plant, mainly used for separating copper, zinc, lead, nickel, gold, and other non-ferrous metal.

【Type】XJK series agitation impeller flotation machine (Seldom used, small capacity); SF flotation machine (Larger volume, better flotation effect); Pneumatic flotation machine (aeration and agitation, high capacity).

【Corollary Equipment】In front: one or two sets of mixing tanks for flotation agent agitation and slurry pulp agitation. Behind: concentrate pond, thickener, or filter

【Flotation Cell】 According to the ore grade, mineral type, and processing capacity to choose, determine the number of flotation cells. It is recommended that carry out the mineral flotation tests to obtain the best procedure plan, like pulp density, time, reagent selection, etc.

【Flotation Reagent】Foaming agent, collecting agent, activating agent, inhibitor, etc.

【Brands】Wemco flotation unit, Fahrenwald Denver, Callow, BGRIMM, etc.

【How to select mining flotation machine】

1. According to the nature of the ore (washability, feed particle size, density, grade, pulp, pH, etc.) and flotation plant scale choose the appropriate flotation machine.

2. The concentration operation is mainly to improve the ore concentrate grade. The flotation foam layer should be thin so that separates the gangue. Using a flotation machine with a large aeration volume is not appropriate. Therefore, there are differences between the froth flotation machine of concentration, roughing, and scavenging.

3. JXSC engineer team is here to help do flotation mining machine selection, price inquiry, and flowsheet design.

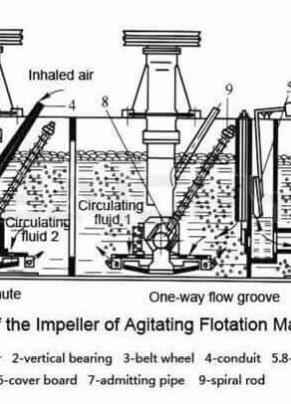

Product Structure

【Flotation Machine Structure】The metallurgist flotation mainly made up of slurry tank, mixing device, aeration device, mineralized bubble discharging device and motor.

【Flotation Machine Working Principle】Flotation process refers to the flotation separation in mineral processing. In the flotation machine, the ore slurry treated with the added agent, by aeration and stir, some of the ore particles are selectively fixed on the air bubbles and floats to the surface of the slurry and is scraped out. The rest is retained in the pulp, thus achieve the purpose of separating different minerals. The complete froth flotation process in metallurgy consists of rougher flotation, concentrate flotation and scavenging flotation.

【Flotation Method】Froth flotation of sulphide ores, mainly have differential flotation and bulk flotation process, improve the flotation recovery rate of fine - particle.

【Flotation Cell Manufacturer】JXSC specializes in the production of a full set of mineral processing equipment, and cooperates with the Mining Research Institute to design a scientific and reliable mineral processing flowsheet, supply gold flotation, copper flotation, zinc flotation, and the like ore flotation units.

Technical Parameters

| Model | Volume(m3) | Cell Size(mm) | Impeller Dia.(mm) | Impeller Speed(r/min) | Capacity(m3/min) | Power(kW) | Singe cell weight(kg) |

| SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 468 |

| SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 805 |

| SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1373 |

| SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 2138 |

| SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2–4 | 15/1.5 | 2582 |

| SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4–8 | 30/1.5 | 4129 |

| SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5–10 | 30/1.5 | 4486 |

| SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5–16 | 30×2/1.5 | 8320 |

| SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5–20 | 30×2/1.5 | 9829 |

| Model | Volume (m3) | Capacity (m3/min) | Impeller Diameter (mm) | Impeller Speed (r/min) | Power(kW) | Singe Cell Weight (kg) | |

| For Stirring | For Scraper | ||||||

| XCF-1 | 1 | 0.2 -1 | 400 | 358 | 5.5 | 1.1 | 1154 |

| XCF-2 | 2 | 0.4 -2 | 470 | 331 | 7.5 | 1659 | |

| XCF-3 | 3 | 0.6 -3 | 540 | 266 | 11 | 1.5 | 2259 |

| XCF-4 | 4 | 1.2 -4 | 620 | 215 | 15 | 2669 | |

| XCF-8 | 8 | 3.0 -8 | 720 | 185 | 22 | 3958 | |

| XCF-16 | 16 | 4-16 | 860 | 160 | 37 | 6520 | |

| XCF-20 | 20 | 5-10 | 910 | 155 | 45 | 9200 | |

| XCF-24 | 24 | 4-24 | 950 | 153 | 55 | 9660 | |

| XCF-30 | 30 | 7-15 | 1000 | 141 | 55 | 14810 | |

| XCF-38 | 38 | 10 -38 | 1050 | 136 | 55 | 17000 | |

| XCF-40 | 40 | 10-38 | 1050 | 138 | 75 | 17500 | |

| XCF-50 | 50 | 10-25 | 1120 | 110 | 90 | 22000 | |

| XCF-70 | 70 | 13-50 | 1200 | 103 | 90 | 26200 | |

| Model | Volume (m3) | Capacity (m3/min) | Impeller Diameter (mm) | Impeller Speed (r/min) | Power(kW) | Singe Cell Weight (kg) | |

| For Stirring | For Scraper | ||||||

| KYF-1 | 1 | 0.2-1 | 340 | 281 | 4 | 1.1 | 826 |

| KYF-2 | 2 | 0.4-2 | 410 | 247 | 5.5 | 1419 | |

| KYF-3 | 3 | 0.6-3 | 480 | 219 | 7.5 | 1.5 | 1885 |

| KYF-4 | 4 | 1.2-4 | 550 | 200 | 11 | 2206 | |

| KYF-8 | 8 | 3.0-8 | 630 | 175 | 15 | 3600 | |

| KYF-16 | 16 | 4.0-16 | 740 | 160 | 30 | 5900 | |

| KYF-20 | 20 | 5-20 | 780 | 155 | 37 | 8240 | |

| KYF-24 | 24 | 4.0-24 | 800 | 150 | 37 | 8540 | |

| KYF-30 | 30 | 7-30 | 900 | 141 | 45 | 13820 | |

| KYF-38 | 38 | 10-38 | 880 | 139 | 45 | 16500 | |

| KYF-40 | 40 | 10-38 | 950 | 138 | 55 | 17000 | |

| KYF-50 | 50 | 10-40 | 1030 | 120 | 75 | 22000 | |

| KYF-70 | 70 | 13-50 | 1120 | 110 | 90 | 26200 | |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.