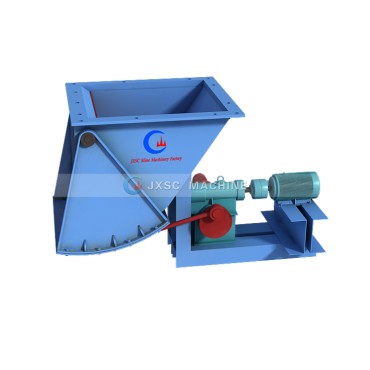

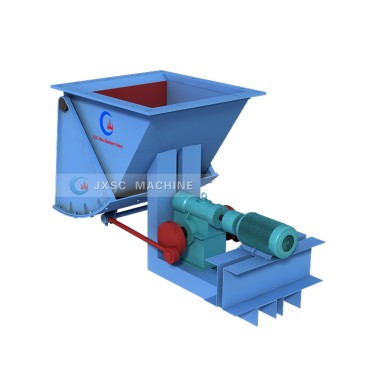

Plunger Ore Feeder

【Capacity】10-130 TPH

【Procesible Material】Rock gold ore/ rock coltan ore/ rock tin ore/ rock tungsten ore/rock iron ore/ rock manganese ore/ rock chrome ore/ stones/ gravel/ coal/ granite/ marble, etc.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

Plunger Ore Feeder is widely used in mineral extraction, the coal industry, the building materials industry, the chemical industry, and others. An ore feeder is suitable for feeding small particle materials in an ore bin, especially for the feeding process of a ball mill with a belt conveyor. It can deliver blocky and granular materials from the storage silo to the receiving device evenly, regularly, and continuously in production.

A pendulum feeder/ plunger ore feeder is a mining auxiliary equipment of mineral transport machinery. It is suitable for short-moment distances, according to a certain amount of small and large proportions of material transport. Its grain size is less than 35 ~ 100 mm; not suitable for viscous materials.

The vibratory feeder is suitable for ore dressing, coal mines, the chemical industry, and other departments to send granular materials from the storage tank through the hopper to various types of receiving a device. The pendulum feeder is not suitable for conveying dry powder or is too large size of the material, otherwise, there will be dust pollution and outlet blockage.

Plunger Ore Feeder is suitable for small pieces of material and granular material with a particle size below 120 mm. The device is simple in construction, cheap in price, and convenient in management. However the accuracy of the work is poor, feeding is not continuous, measurement is more difficult, used for ore and other hard materials, wear and tear is more serious. The powder is easy to fly and plug, so it is unsuitable for transporting powder materials.

Product Structure

Motors via a V-belt drive speed reducer. Power passed to the adjustable eccentricity, as slow eccentric. Adopted by the eccentric Rod drove swing plate to swing, located above the feeder ore bins, after feeding machine body cavity from the nesting population, uniform time and time again the overboard discharge, ensure the uniform for ball mill feeding process.

Technical Parameters

| Model | Discharge Port Size W*H (mm) | Max Feeding Size(mm) | Feeding Capacity (t/h) | Motor Power (kW) | Weight(kg) |

| 300 x 300 | 300 x 300 | 50 | 10-20 | 1.5 | 265 |

| 400 × 400 | 400 × 400 | 100 | 10-30 | 2.2 | 535 |

| 600 × 500 | 600 × 500 | 200 | 10-50 | 4 | 1045 |

| 700 x 500 | 700 x 500 | 250 | 10-60 | 4 | 1100 |

| 1240 x 980 | 1240 x 980 | 350 | 36-90 | 7.5 | 1710 |

| 1240 x 1100 | 1240 x 1100 | 350 | 50-110 | 11 | 1780 |

| 1240 x 1240 | 1240 x 1240 | 350 | 60-130 | 11 | 1930 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.