Trommel Screen

【Capacity】 0-200 T/H

【Feed Size】≤100 mm

【Processible Material】Ore, coal, sand, gravel, chemical, soil, etc.

【Applications】Medium-fine materials grading & screening in the mining industry, quarry, chemical industry, trommel screen usually equipped with 60-200 mesh sieve, and water flush pipe.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

Trommel screen also knowns as a rotary screen, or gold trommel, is a versatile screening machine that can size and separate feed materials in the mining, quarry, aggregate, and dirt industry. In the mining plant, the gold trommel screen usually works with a grizzly hopper, a vibrating grizzly screen, etc.

【Advantages】

- It is a highly economically viable option adequately suitable for small to large-volume processing gold mining wash plants.

- The screen features various filters for different heavy-duty drums that ensure the complete separation of fine materials.

- The design has end-user flexibility that allows for screen replacements depending on mesh sizes, mini Trommel, and small Trommel screens for sale.

- Multiple layers of screen to enhance the sifting process.

- It features changeable screen plates so worn-out Trommel screen parts can be replaced.

- Trommel screen has high efficiency and a big capacity for different volumes of materials.

- The screen is uniquely designed to facilitate higher capacities, provide longer screen life, and avoid material clogging.

JXSC Trommel Screens can precisely classify materials into multiple sizes from one unit. We offer a wide range of sizes and capacities, custom-made stationary gold wash plants, or portable trommel screens (wheel type) to the needs of individual customers.JXSC Rotary Trommels offers various types of sieve plates (material, mesh, shape) for wide applications. Custom-made 2-3 layers. The Rotary Drum screen has the advantages of simple structure, easy operation, high efficiency, large capacity, easy-clean, and no jam.

If you want to buy a Trommel Screen, this information (basic: feed material particle size, density, feed solids capacity, moisture, clay. What’s more, knowing your requirements such as the type of screen media, protective safety covers, etc.) helps you to select the right machine. JXSC has produced and built the portable Trommel screen and portable Trommel screening plant over decades. Welcome to contact us to get the best Trommel screen price.

Product Structure

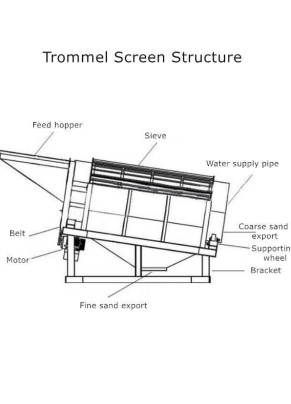

【Trommel Screen Structure】

The trommel screen mainly comprises a transmission device, feeding hopper, screen, bracket, water supply pipe, etc.

【Work Principle of Trommel Screen】

As the rotary drum screen rotates, the raw feed materials are lifted and fall. The tumbling and lifting actions help to break down agglomeration, and separate materials into different sizes. As the rotation continues, the smaller size material is filtered through sieve mesh, while the larger material finally discharges at the end.

Technical Parameters

| Model | Screen Size (mm) | Feeding Size (mm) | Drum Diameter (mm) | Drum Length (mm) | Capacity (t/h) | Power (kW) |

| GT0513 | ≤20 | ≤80 | 500 | 1300 | 1-5 | 3 |

| GT0813 | ≤20 | ≤80 | 800 | 1300 | 5-10 | 4 |

| GT1015 | ≤20 | ≤80 | 1000 | 1500 | 10-15 | 5 |

| GT1020 | ≤25 | ≤80 | 1000 | 2000 | 15-20 | 5.5 |

| GT1225 | ≤25 | ≤100 | 1200 | 2500 | 20-50 | 7.5 |

| GT1530 | ≤25 | ≤100 | 1500 | 3000 | 40-70 | 11 |

| GT1545 | ≤25 | ≤100 | 1500 | 4500 | 70-100 | 15 |

| GT1848 | ≤50 | ≤100 | 1800 | 4800 | 100-150 | 22 |

| GT2055 | ≤50 | ≤100 | 2000 | 5500 | 150-200 | 30 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.