A heavy medium is a heavy-fluid or heavy suspension fluid with a density greater than that of water (1g/cm3). The process of separating ore particles in heavy media is called Dense Media Separation / Heavy Media Separation (DMS / HMS).

Dense Media Separation (DMS) Plants

Release time:17 February 2022The heavy medium separation method is an advanced gravity beneficiation method. Following the Archimedes principle – particles smaller than the density of the heavy medium will float, and particles larger than the density of the heavy medium will sink in the medium.

The fluid movement and particle sedimentation are no longer the main factors contributing to the layering, and the property of the medium itself is an important factor in the separation.

Heavy medium includes heavy-fluid or heavy suspension fluid. Because heavy-fluid is expensive and toxic, it is rarely used.

The heavy suspension fluid is a suspension composed of finely pulverized high-density solid particles and water. High-density solid particles act to increase the density of the medium and are called medium solid.

Medium Solid Selection

【Overall Consideration】

1. High enough density. To make the required density of suspension liquid.

2. Easy to recycle. It can be separated by simple ways like magnetic separation, flotation, or classification.

3. Wide range of sources, low prices, and no harmful impurities.

【Common Medium Solids】

| Type | Density (kg/m3) | Moh’s hardness | Max. suspension density (kg/m3) | Magnetism | Recovery method |

| Silicoferrite | 6900 | 6 | 3800 | strong magnetism | magnetic separation |

| Galena | 7500 | 2.5-2.7 | 3300 | non magnetic | flotation |

| Magnetite | 5000 | 6 | 2500 | strong magnetism | magnetic separation |

| Pyrite | 4900-5100 | 6 | 2500 | non magnetic | flotation |

| Arsenopyrite | 5900-6200 | 5.5-6 | 2800 | non magnetic | flotation |

Heavy medium beneficiation is a method of strict density separation, which can effectively separate ore with a mineral density difference of about 0.1. Therefore, DMS methods are widely used in the separation of coal and various metal ores and non-metallic ores.

Direct separate clean coal and waste rock; separate coarse waste tailings and rough concentrate.

For the ordinary gravity separation method, the lower limit of the feeding ore is about 2-3mm (the coal is 3-6mm).

When sorting by heavy medium cyclone, the lower limit of the ore size can be reduced to 0.5mm.

The upper limit of the ore particle size is related to the ore size, embedding characteristics, and equipment size. In usually, the ore is 50-150mm, and the coal is 300-500mm.

DMS can greatly reduce the surrounding rock and waste rock under the same processing capacity, reduce ore grinding consumption, thus reduce production costs.

Undoubtedly, heavy medium mineral processing is one of the most promising directions for improving the comprehensive economic benefits of non-ferrous metal mines.

【Limits】

Restricted by the density of medium solid, it is difficult to prepare a suspension with a high density, so the DMS method is difficult to obtain a high-grade final concentrate. Only can remove low-density monomer gangue and surrounding rock, preventing them enter the grinding operation.

The heavy medium beneficiation process includes ore preparation, medium preparation, ore beneficiation, medium removal, and medium regeneration.

What mineral processing machine do we supply?

【Ore Preparation】

crushing, screening, and washing. In order to improve the screening efficiency, we usually adopt a wet type screening method to wash the mud.

【Medium Preparation】

Crush and grind bulk ferrosilicon or magnetite (used as media solid) to the required size in advance. The crushing and grinding process usually consists of a jaw crusher, ball mill, spiral classifier, screen, etc.

【Ore Beneficiation】

Ore beneficiation is the separation of light and heavy minerals in the heavy medium separation machine. The density of the suspension is kept stable during the sorting process, so it is necessary to take frequent samples for measurement.

【Medium Removal】

Light and heavy mineral products obtained after the ore beneficiation process are carried with suspension, which is to be recovered.

The de-medium process is divided into two sections: the first section is screened out of the thick medium and returned directly to the process; the second section is flushed with water on the screening machine to wash away the medium solid adhering to the ore.

The two-stage screening can be carried out on the same sieve machine.

【Medium Purification】

Generally, the amount of thick medium that is removed from the light and heavy minerals is about 90% to 95% of the total used medium, and the rest of the medium solid adhered to the ore is flushed to the dilute medium. This part of the medium is seriously polluted and needs to be purified and concentrated. This whole operation is called Media Purification.

Use magnetic separation, flotation, or gravity separation to recover the medium solid in the dilute medium, and then dehydrated and concentrated by means of a water cyclone and finally reconfigured into a suspension with a proper density to return to the process.

Heavy Medium Separation Equipment

There are 4 types of heavy liquid separation machines for industrial applications: deep trough type, shallow trough type, vibrating type (heavy medium vibrating chute), and centrifugal type (heavy medium cyclone).

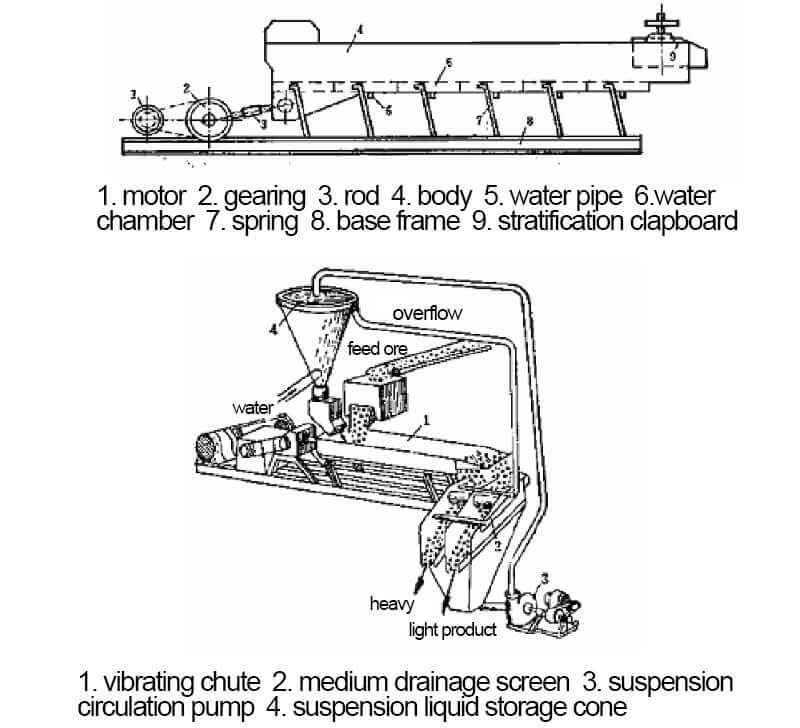

Heavy medium vibration chute

Heavy medium vibration chute uses heavy flotation liquid to separate coarse ore (hematite, manganese ore, and other ferrous metals) in the vibration process, feed ore size is generally 75-6mm.

【Working Principle】

Under the action of chute shaking and rising water flow, the heavy suspension liquid and ore form a high concentration of stratified sedimentation bed.

The heavy minerals with a high density are distributed in the bottom and are discharged; the light minerals are distributed in the upper part.

The light and heavy minerals are separated from the medium by a dissociation sieve (vibration screen), and the sieved medium is returned to the medium cone for recycling.

【Advantages】

- Simple process, easy to prepare

- High capacity, 7t/h per 100mm chute width.

Vibration chute structure

Dense medium cyclone working principle

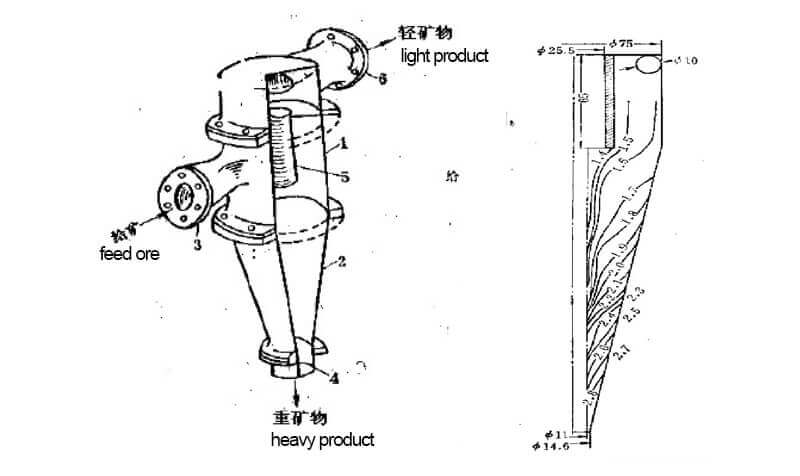

Dense medium cyclone

The difference between heavy medium cyclone and regular hydro cyclone is that the medium to be fed is not water but a suspension liquid.

After sorting by a heavy medium cyclone, heavy minerals and some media are discharged along with the sedimentation port, and light minerals and the rest of the medium are discharged from the overflow port, de-medium separately, obtain the heavy and light products.

【Advantages】

1. High processing capacity, high sorting efficiency, and lower feeding limit, up to 0.5 mm;

2. Due to the concentration effect, a lower density suspension can be used to obtain a higher sorting density;

3. Can use high particle size suspension liquid;

4. Simple structure, no power required.

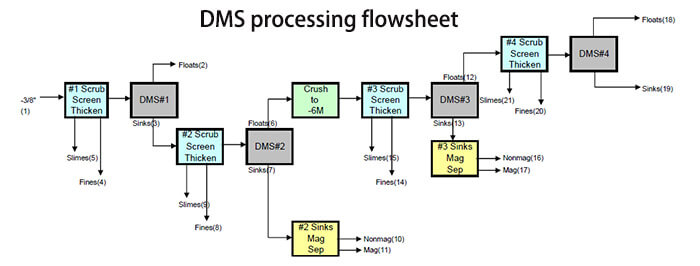

DMS Plants & Cases

Dense Media Separation Case

Mineral: Diamond

Capacity: 200TPH

Description: DR Congo Customer 200TPH diamond Processing plant, including feeding system, sand washing machine, crush machine, sieving, and DMS system

In a Dense Media Separation (DMS)/ Heavy Media Separation( HMS) plant, powdered ferrosilicon (an alloy of iron and silicone) is suspended in water to form a fluid near the density of diamond (3.52 g/cm3), to which the diamond-bearing material is added to begin the separation process of the heavier minerals from the lighter material. Additional separation of the denser material occurs by centrifuge in “cyclones” that swirl the mixture at low and high speeds, forcing the diamonds and other dense minerals to the walls and then out the bottom of the cyclone. Wastewater rises at the center of the cyclones and is sucked out and screened to remove waste particles. The DMS process results in a concentrate that generally weighs less than one percent of the original material fed into the plant at the beginning of the process.

Dense Media Separation Advantages

1. Lower basic investment and operating costs

2. Can deal with low-grade resources and improve ore production

3. Environment-friendly operation

Although heavy media separation has been recognized since the last century and used in coal washing, mineral processing, hydrometallurgy, or pyrometallurgy processes, as a general process, heavy medium separation is not really shown before fine grinding of ore. It is proved that the method of heavy medium separation can effectively separate diamond and other precious stones and treat copper, lead, and zinc ores. In some cases, effective recovery of gold and PGM, the improved method can also be effective separation of non-metallic minerals, like barite, fluorite, and other industrial minerals. In the non-mine field, heavy medium separation technology can be used to treat waste vehicle debris, renewable resources, industrial and municipal waste, and electronic waste.

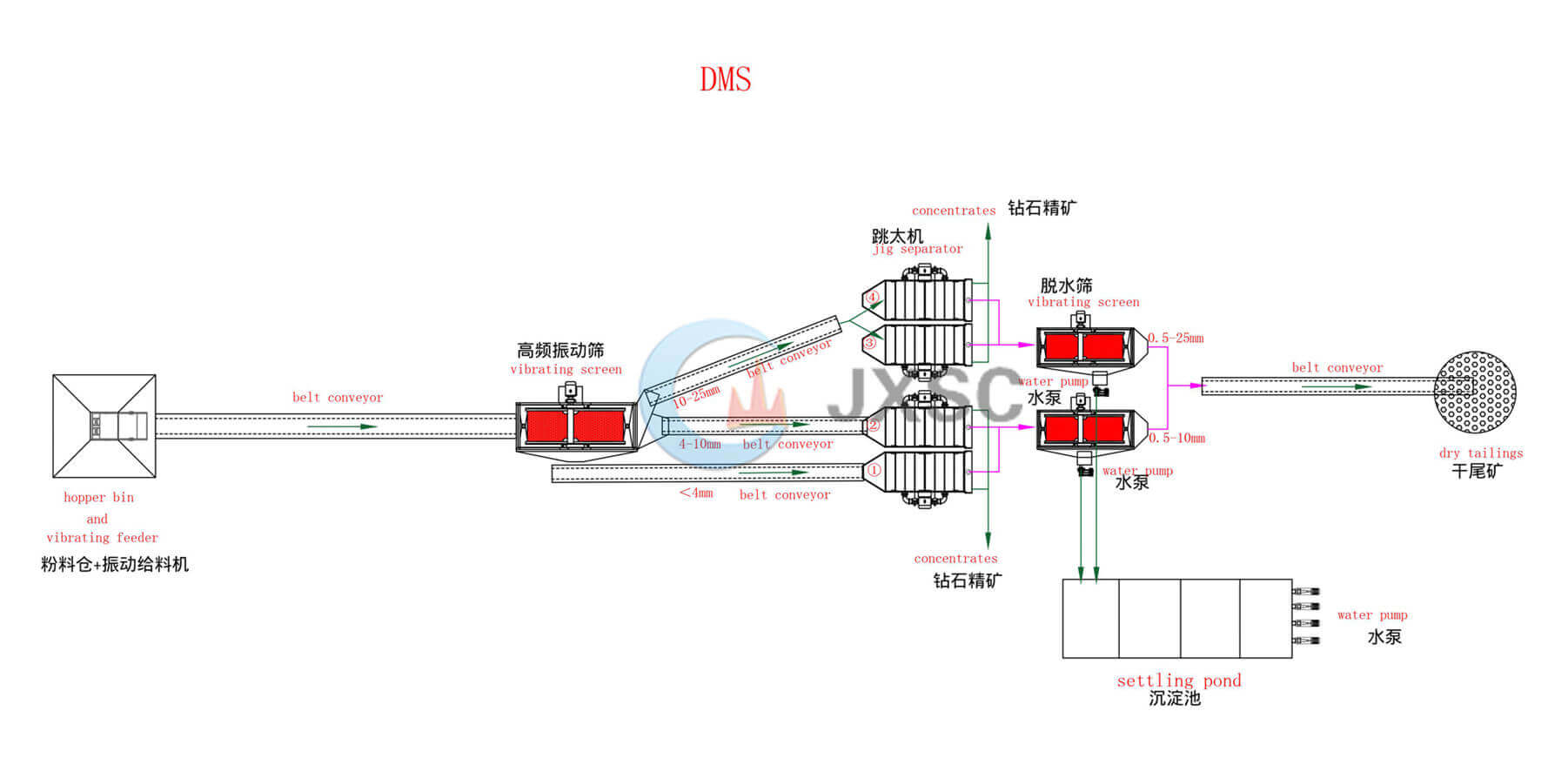

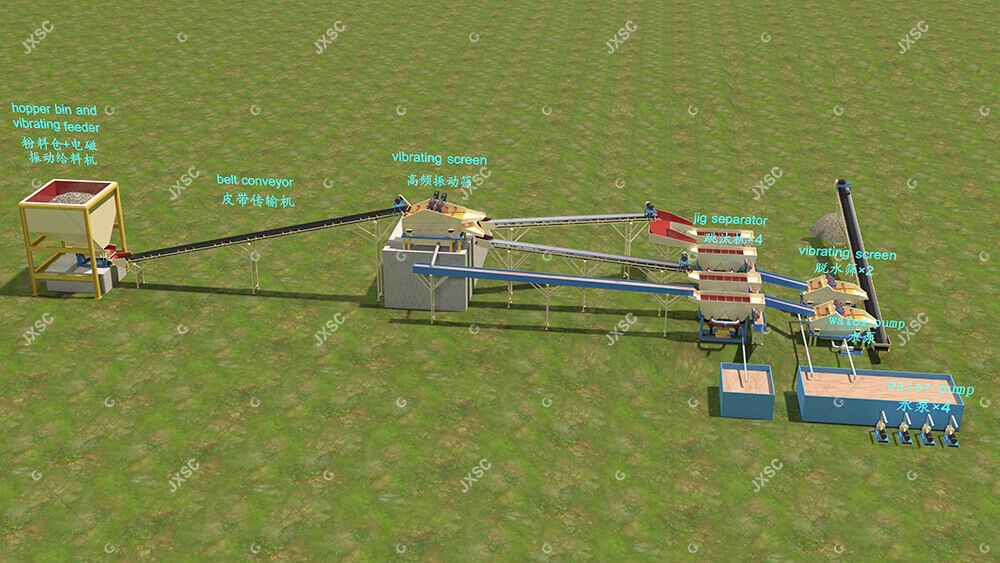

Dense Media Separation Plant

Process Explanation

The raw ores convey to the high-frequency vibrating screen, three particle sizes were graded, then each size goes to a different jig separator for diamond separation.

0-5mm under-screen material goes to 1st jig, 5-10mm middle material goes to 2nd jig, 10-20mm over-screen material goes to 3rd jig, sorting out different particle sizes to different jigs enjoy higher recovery rate.

The tailing of jigs flows into the dewatering screen machine for water recycling. Recycled water can be reused.

Related Product

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.