Filter Press Feed Pump

【Equipment Flow】 30-215m3/h

【Equipment Vertical Head】 40-90m

【Application Place】 Solid-liquid separation of plate and frame filter press

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The special feeding pump for filter press is widely used to feed filter press in petroleum, chemical, starch, pharmaceutical, pesticide, dye, paint, leather, paper, food, and other industries.

Filter Press Feed Pump Features

- Wide runner, with good passability

The filter press feed slurry pump adopts a semi-open impeller with a wide flow channel and good passability. There is no blockage when conveying slurry-containing particles, and the particles will not be stuck between the impeller, the pump body, and the pump cover, thereby making up for The effect that the general centrifugal pump can’t achieve. - Simple structure and easy maintenance

The filter press sludge feed pump has a simple structure and is easy to maintain. The unique structure design can be completed without removing the pipeline when repairing and replacing the impeller, seal, bearing, and other wearing parts. - Unique hydraulic design and impeller installation method

The filter press feed pump adopts a unique hydraulic design and impeller installation method to ensure that its performance curve is steeper than ordinary impurity pumps. It is very suitable for the change of resistance when the filter press feeds to achieve large flow, low-pressure feeding, and the purpose of small flow, high-pressure filtration. Its special hydraulic performance coincides with the gradual filter press process from the cavity to filling and then drying. In the early feeding stage, the valve is not used to control the motor overload caused by excessive flow. At the same time, the low pressure will not impact the filter plate frame, which reduces the damage to the filter cloth on the filter plate frame and will not impact the filter plate to cause vibration. Small flow and high pressure make not easy to hold the pump. Especially in the later squeezing period, the unique impeller installation method and auxiliary impeller function of the same pump under high pressure ensure that there is basically no leakage at the shaft seal.

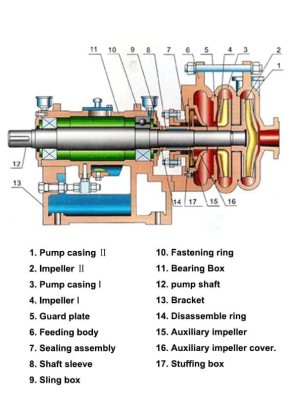

Product Structure

The impeller of the feed pump of the filter press adopts a rear-opening type, wide flow channel, not easy to block, anti-crystallization, and particle resistance. The sealing form adopts advanced mechanical sealing technology, and the sealing end surface is made of high-quality solid carbide, which has good wear and corrosion resistance. Suspension parts adopt three imported bearings, and the suspension parts are long, so the pump runs smoothly, has low noise, good sealing effect, convenient maintenance, and long service life. It is suitable for supporting various filter presses.

Among them, the impeller is a wheel disk with moving blades, and an impulse steam turbine rotor component. The impeller is composed of blades, disks, and wheel covers. The gas flows between the impellers to obtain energy.

The impeller is divided into a primary impeller, a secondary impeller, and an auxiliary impeller. The first and second impellers play the role of diversion and conveying liquid, and the auxiliary impeller functions as a sealing and sealing function. The long-term use of the primary and secondary impellers will cause wear, affecting the pump's efficiency. New parts need to be replaced. The secondary impeller is less worn has a long service life, and usually does not need to be replaced.

Technical Parameters

| Model | Pump Flow(m3/h) | Vertical Head(m) | Rotating Speed(r/min) | Power(kW) | Supporting Filter Press(m2) |

| 50SYA65-22 | 20-70 | 30-65 | 1450 | 22 | 40-80 |

| 50SYA75-30 | 20-70 | 35-75 | 1450 | 30 | 80-100 |

| 50SYA76-37 | 20-100 | 30-76 | 1450 | 37 | 120-160 |

| 65SYA80-45 | 35-125 | 35-80 | 1450 | 45 | 160-200 |

| 80SYA65-45 | 40-140 | 30-65 | 1450 | 45 | 160-200 |

| 80SYA75-55 | 50-160 | 35-75 | 1450 | 55 | 250-300 |

| 100SYA75-75 | 70-245 | 30-75 | 1450 | 75 | 300-350 |

| 100SYA80-90 | 50-280 | 35-80 | 1450 | 90 | 350-400 |

| 125SYA70-90 | 80-300 | 30-70 | 1450 | 90 | 350-400 |

| 150SYA75-110 | 80-330 | 35-75 | 1450 | 110 | 400-600 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.