Electrostatic Separator

【Capacity】 1-3 t/h

【Feeding Size】 0-3 mm

【Application】 Non-ferrous metal and black metal, such as iron ore, zircon, cassiterite(tin), ilmenite, rutile, primary limonite, beach placer, manganese ore, titanium, tantalum-niobium, monazite and primary retiles.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The ARC type Electrostatic Separator is mainly used for separating a small number of metallic conductor minerals from nonmetallic materials, especially for separating and purifying placer ores.

Application of Magnetic Separator

1. Selection of heavy minerals from coastal places, such as sandy gold.

2. beneficiation of nonferrous and rare metallic minerals such as Scheelite and Cassiterite, wolframite and Scheelite, primary ilmenite, and gangue.

3. The concentration of Ferrous minerals, such as ultrapure iron concentrates, chromite, and manganese.

4. Separating non-metallic minerals such as graphite, quartz, feldspar, asbestos, and apatite.

5. Separating non-ferrous and non-metallic materials such as copper, tin, aluminum, and plastic from waste.

Types of magnetic separators: Drum magnetic separator, roll separator, tube separator, ARC type magnetic separator.

We have supplied the magnetic separator design service, and manufacturer customized magnetic separation equipment since 1985, worth your trust.

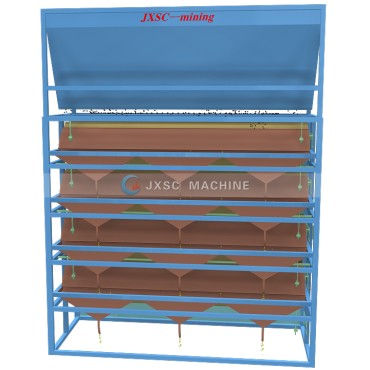

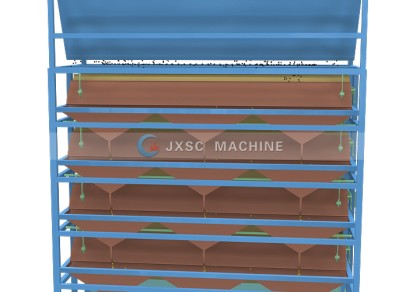

Product Structure

【Magnetic Separator Working Principle】

1. The machine is equipped with chassis and it should be placed vertically when installed.

2. It should be grounded well. The ground line should be buried with an angle iron or water pipe into a 2-3 meters wet underground place.

3. High-voltage cables should be in the plastic tube to prevent leakage.

4. Ore storage heating wire should be 4.5 square millimeter cable. There are high and low-temperature switches in the control cabinet.

Operating Method

1) Check that there is no foreign matter in the electric separator first, avoid the connection of the negative electrode tube and the positive electrode plate;

2) Voltage regulator KNOB must be back to zero before slowly boost voltage, boost voltage to see if the microammeter current is abnormal, such as current is too large, please check the cause of leakage;

3) When the required voltage is set, start feeding work;

4) Every work hours, should open the door to clean steel pipe and steel dust, dust must use a long plastic brush, remember not to close the steel pipe, in order to avoid electric shock;

5) At the end of the work or inspection of the equipment must be Knob to zero, and then with a discharge rod steel pipe and steel plate directly connected to discharge. (discharge rod is made of Long Plastic Rod, front end ties up about 20cm bare copper wire) the discharge will see Bright High Voltage ARC;

6) When the continuous discharge occurs in the working process, the voltage should be lowered in time to eliminate the fault.

Technical Parameters

| Model | BXJ-2A4-30 | BXJ-2A5-60 |

| Capacity (T/H) | 1-2 | 1-3 |

| Feeding Size (mm) | 0-3 | 0-3 |

| Feeding Speed (cm/s) | 10-15 | 10-15 |

| Arc-Plate Size | 1600 | 1600 |

| Power Consumption (w) | 125 | 125 |

| Operation Voltage (kV) | 0-60 | 0-60 |

| High Voltage Current (mA) | 0-10 | 0-10 |

| Weight (kg) | 1688 | 2100 |

| Overall Size (m) | 2.1*1.6*2.3 | 2.1*1.6*2.5 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.