No matter where your operation is, no matter what your processing requirements are, JXSC Mine Machinery Factory is there to help ensure your minging ore processing plant is optimized to deliver the lowest cost per ton. Here we will explain the gold processing plant to you.

Gold Processing Plant

Release time:12 October 2021Alluvial Gold Mining Process

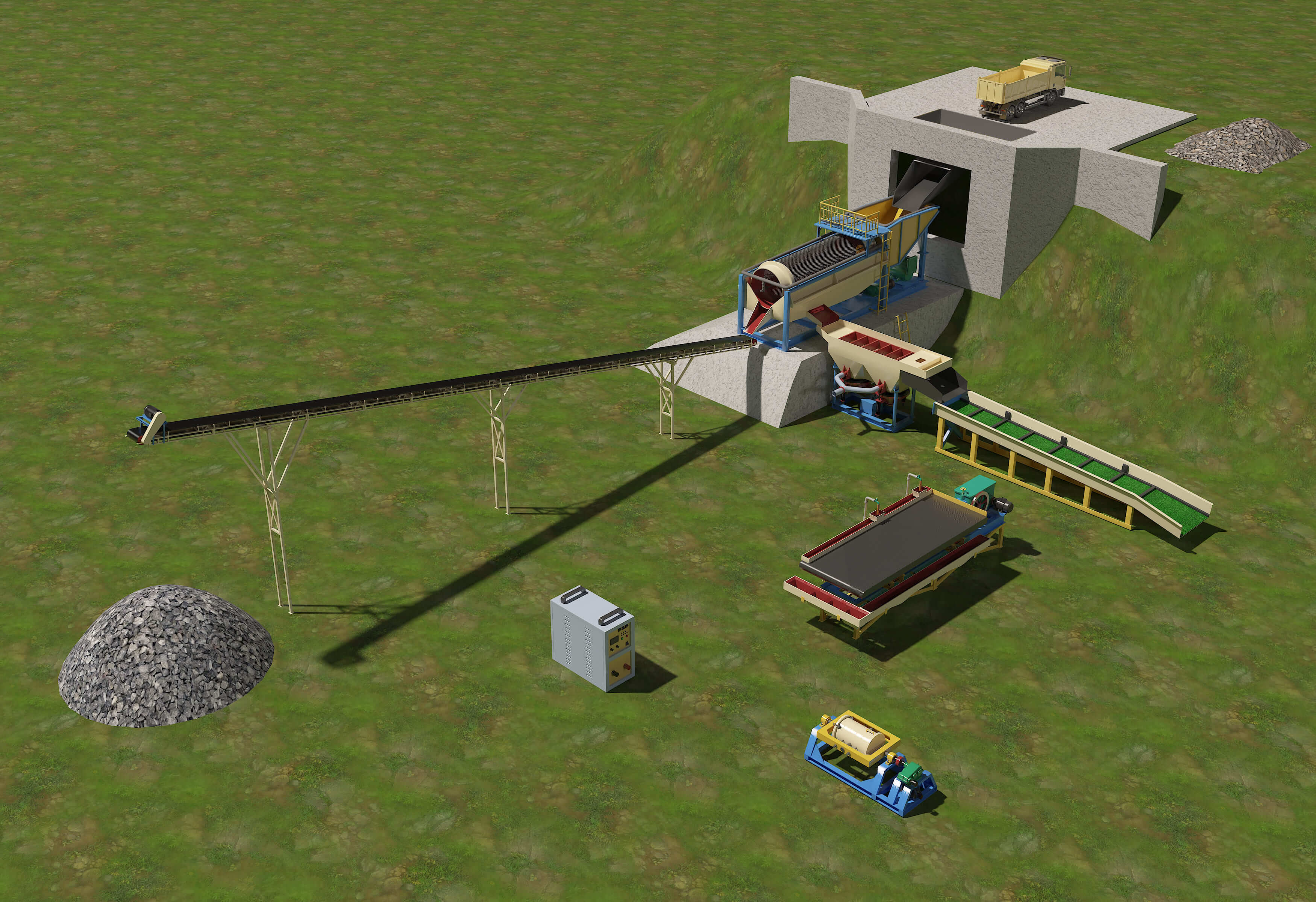

Alluvial Gold Washing Plant

Ore: Alluvial gold without sticky clay

Capacity: Customized

Equipment Used:Trommel screen + jig machine + sluice box + shaking table + gold amalgamator + gold smelting machine.

Processing:

- The raw ore feed into the trommel screen for washing a few little clays, and can separate the gravel or stone which do not contain the gold inside, which can transfer away by the belt conveyor.

- The jig machine for catching the big particle around 2-20mm bigger gold particles or nuggets, and a sluice box capture the gold particle or nuggets again in case they flow away from the tailings.

Please note the sluice box can be designed with different lengths and widths like 2m,4m,6m length,1m width or 0.5m width, etc., - The concentrates under the jig machine go to the shaking table again for a more good separation effect. Because the concentrates still have a little sand. Use the shaking table can separate the sand from the gold in very good effect.

This washing plant is very suitable for recovering alluvial gold ore that doesn’t contain sticky clay. If the raw ore contains much sticky clay, we will recommend a trommel scrubber instead of a trommel screen.

The capacity for this washing plant can be customized as per request such as 10tph,50tph,100tph, etc.,

Placer Gold Mining Process

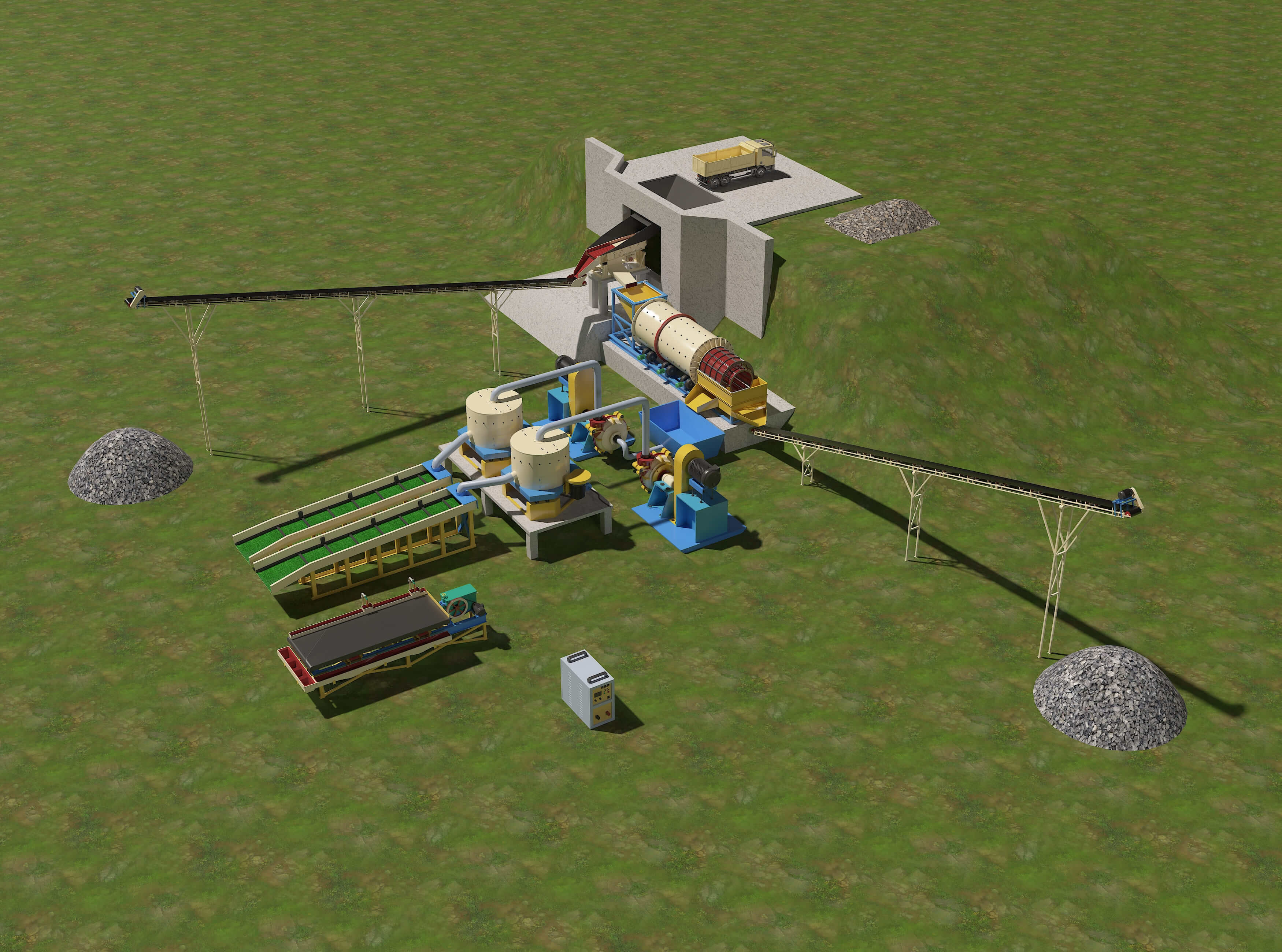

Placer Gold Processing

Ore: Placer gold with sticky clay

Capacity: Customized

Equipment Used:Trommel scrubber + vibrating feeder + centrifugal concentrator + slurry pump + sluice box + shaking table

Processing:

- Loader or Excavator feed raw ore into the hopper;

- Vibrating feeder feed trommel scrubber. Trommel scrubber is to wash off clay from ore, and screen out different sized particles.

- Overscreen materials of trommel are transported to far place by belt conveyor, this is waste sand.

- Under screen materials of trommel are sent to the centrifugal concentrator by a slurry pump, Centrifugal concentrator is to concentrate 0-5mm fine gold.

- Tailings of centrifugal concentrator will be sent to sluice box for recovering more gold.

- Concentrates of sluice box and centrifugal concentrator are sent to shaking table for fine concentration gold in order to increase the purity of gold content.

This flowchart is suitable for any type of alluvial ores, especially placer gold with sticky clay, and gold particles with 5mm below.

If the gold particle size is bigger than 5mm, add one more sluice box for recovering gold nuggets with 5mm up.

Alluvial Gold & Rock Gold Mining Process

Alluvial & Rock Gold Plant

Ore: Alluvial gold and rock gold

Capacity: Customized

Equipment Used: Trommel screen + gold concentrator + sluice box + belt conveyor + jaw crusher + hammer crusher + shaking table

Processing:

- The raw ore feeds into the trommel screen for washing a few little clays and can separate the gravel or stone which need to crush & grind to get the inside gold. The separated gravel can transfer to the next jaw crusher by belt conveyor.

- The trommel screen is designed with two layers screen, the bigger than 20mm to a jaw crusher, which can crush the big stone into smaller parties.

- The output from the jaw crusher goes to the hammer crusher via the belt conveyor.

- The hammer crusher the smaller stone less than 2mm to release the inside gold.

- The medium particle size is around 6-20mm. Which contain gold nuggets goes to sluice box to capture the nuggets by the sluice carpet directly.

- The smaller size <6mm goes to the gold concentrator for catching the gold first, the concentrated from the gold concentrator goes to the shaking table for separating the gold again to update the recovery rate.

For this flowsheet, the trommel screen is designed with mobile wheels, which can easily move from one site to another site. Or you can choose a stationary one.

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.