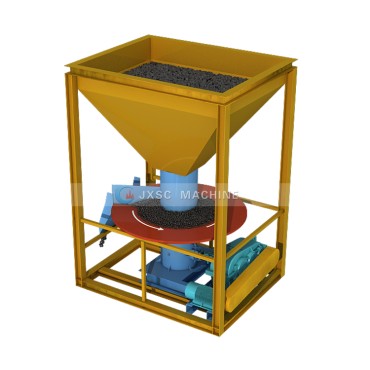

Disk Feeder

【Capacity】 1.8-88 T/H

【Disk Diameter】 600-2000 mm

【Feeding Size】 ≤80 mm

【Application】 Various non-sticky materials, metallurgy, mining, building materials, coal, electricity, and other feed sectors.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The main function of the disk feeder/disc feeder is to provide material supply for other equipment. The use of the disc feeder enables the material to enter one piece of equipment evenly so that the next process can work normally and saves labor moreover, the utility model protects the performance of the equipment and extends the service life of the whole production line equipment. Disc feeder is an indispensable accessory product of process mining.

A variety of non-adhesive materials as an industrial feeder for transporting powder, or small material, such as coal, cement, clinker, limestone, shale, coal gangue, clay powder, granular, or small block material.

We supply a series of ore feeder products, magnetic feeders, and vibrating feeder designs also available.

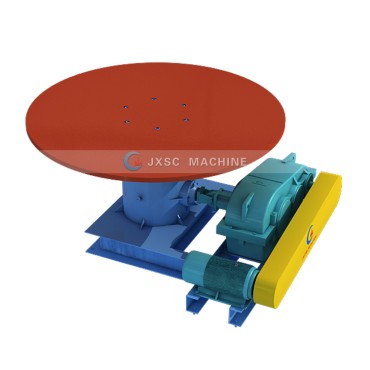

Product Structure

【Disk Feeder Working Principle】DisK feeder comprises the driving device, feeder unit, belt conveyor for metering use, and metering device. A set of driving devices drives the feeder and belt conveyor. The driving device of the electromagnetic clutch can switch off or switch on the feeder. There is a speed inspecting device to test the belt conveyor speed which shall be less than 1m/s, and a measuring bar to adjust the weighing roller's position to prevent deflection.

The feed port of the disc feeder comprises the receiving sleeve and the adjustable adjusting sleeve under the receiving sleeve. The material falls from the receiving sleeve to the adjusting sleeve and then leaks out through the gap between the disc and the adjusting sleeve And the scraper scrapes the disc's material. The feeding quantity can be adjusted by adjusting the gap size between the set and the disc and the position of the scraper. The size of the receiving sleeve and the adjusting sleeve can be determined by the disc feeder's hourly feeding quantity and the DISC's radius. The height of the sleeve is adjusted mainly by rotating the screw rod fixed on both sides of the sleeve to drive the sleeve up and down.

Technical Parameters

| Model | Disk Diameter (mm) | Rotate Speed (r/min) | Max. Feeding Size(mm) | Motor Power(kW) | Capability (t/h) | Weight(kg) |

| YG600 | 600 | 10 | 25 | 1.1 | 1.8-4 | 410 |

| YG800 | 800 | 9 | 30 | 1.5 | 3.5-7 | 600 |

| YG1000 | 1000 | 9 | 40 | 2.2 | 1.8-16.7 | 800 |

| YG1300 | 1300 | 9 | 50 | 3 | 4-28 | 1110 |

| YG1600 | 1600 | 7 | 60 | 4 | 7-49 | 1980 |

| YG1800 | 1800 | 7 | 70 | 5.5 | 9-60 | 3070 |

| YG2000 | 2000 | 7 | 80 | 5.5 | 14-88 | 3260 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.