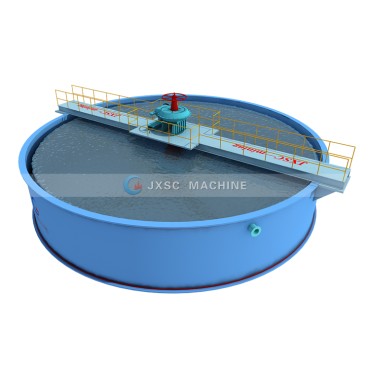

Thickener

【Capacity】 1.3-1440 t/d

【Application】 Thickener is suitable for dewatering concentrates and tailings in the mineral processing plant. It is widely used in metallurgy, chemical, coal, non-metal ore dressing, environmental protection, and other industries. The high-efficiency thickener is not only a liquid-solid separation sedimentation device but a new type of dewatering device that combines the filtration characteristics of the mud layer.

Chat Online on WhatsApp

Chat Online on WhatsAppAdvantages

The thickener is applicable to concentrate and tailings dewatering treatment in mining applications, widely used in metallurgy, the chemical industry, coal, non-metallic mineral processing plants, environmental protection, and other industries. The high-efficiency mining thickener is not a gravity separation equipment, but a piece of dewatering equipment combined with characteristics of mud filtration.

Other dewatering machines you may interested in.

【Features】

(1) Adding flocculants to increase the particle size of settling solid particles, thus speeding up the settling speed.

(2) Installing inclined plates to shorten the settlement distance of ore particles and increase the settlement area.

(3) Giving full play to the functions of flocculation, filtration, compression, and enhancement of the treatment capacity of the thick phase layer of mud deposition.

(4) Equipped with complete automatic control facilities.

Product Structure

The thickener (high-efficiency thickener) generally consists of a thickener tank, a truss, a transmission, a truss lifting device, a feeding device, a discharging device, and a signal safety device. The main feature of the concentrator (high-efficiency concentrator) is to add a certain amount of flocculant to the slurry to be concentrated, so that the ore particles in the slurry form floccules, accelerate the sedimentation speed, and thereby achieve the purpose of improving the concentration efficiency.

A good concentrator settling process must have three stages that are not in short supply. These are the stage of coagulation and destabilization, the stage of coagulation and granulation, and the stage of filtration and compression. However, the realization of these three stages must have certain equipment to ensure that the flocculation reaction cannot be sufficient, and the effect of solid-liquid separation is impossible to achieve the desired state.

As the large flocs gather more and more, the ideal dense phase layer at the bottom of the deep cone concentrator is formed. In the upper part of the dense phase layer, thicker and less stable flocs are deposited, essentially a floating filter medium that has a very beneficial intercepting effect on small particles that escape with the upflow. Under the combined action of the larger head and the material gravity, the sediment at the bottom of the dense phase layer can obtain a large pressure in the bottom stream of the deep cone concentrator, so that the concentration of the material to be discharged is greatly improved.

Technical Parameters

| Center Drive Thickener Technical Parameters | |||||||

| Model | Thickener Tank | Sedimentation Area (m2) | Transmission Speed (r/min) | Motor | Capacity (t/d) | ||

| Diameter (m) | Depth (m) | Model | Power (kw) | ||||

| NZS1 | 1.8 | 1.8 | 2.55 | 0.5 | Y90L-6 | 1.1 | 1.3-5.6 |

| NZS2.5 | 2.5 | 1.8 | 4.9 | 0.33 | Y90L-6 | 1.1 | 5-10.8 |

| NZS3.6 | 3.6 | 1.8 | 10.2 | 0.38 | Y90L-6 | 1.1 | 5-22.4 |

| NZS6 | 6 | 2.956 | 28 | 0.35 | Y90L-4 | 1.5 | 14-60 |

| NZS8 | 8 | 3 | 50.2 | 0.27 | Y132S-6 | 3 | 25-120 |

| NZS9 | 9 | 3 | 63.5 | 0.25 | Y132S-6 | 3 | 32-150 |

| NZS12 | 12 | 3.6 | 113 | 0.19 | Y132S-6 | 3 | 50-250 |

| NZS15 | 15 | 3.6 | 176 | 0.1 | Y132M2-6 | 5.5 | 70-350 |

| NZS18 | 18 | 3.74 | 255 | 0.2 | Y160M-6 | 7.5 | 100-560 |

| NZS20 | 20 | 4.4 | 315 | 0.2 | Y160M2-8 | 7.5 | 200-1440 |

| NZS24 | 24 | 4.716 | 452 | 0.1 | Y180L-8 | 11 | 200-1440 |

| Peripheral Rack Drive Thickener Technical Parameters | |||||

| Model | Thickener Tank | Sedimentation Area (m2) | Motor Power (kw) | Capacity (t/d) | |

| Diameter (m) | Depth (m) | ||||

| NT-15 | 15 | 3.5 | 177 | 5.5 | 1.3-5.6 |

| NT-18 | 18 | 3.5 | 255 | 5.5 | 5-10.8 |

| NT-24 | 24 | 3.7 | 452 | 7.5 | 5-22.4 |

| NT-30 | 30 | 3.6 | 707 | 7.5 | 14-60 |

| NT-45 | 45 | 5.06 | 1590 | 11 | 25-120 |

| NT-50 | 50 | 4.524 | 1964 | 11 | 32-150 |

| NT-53 | 53 | 5.07 | 2202 | 11 | 50-250 |

Successful Cases

Contact Us Now

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.