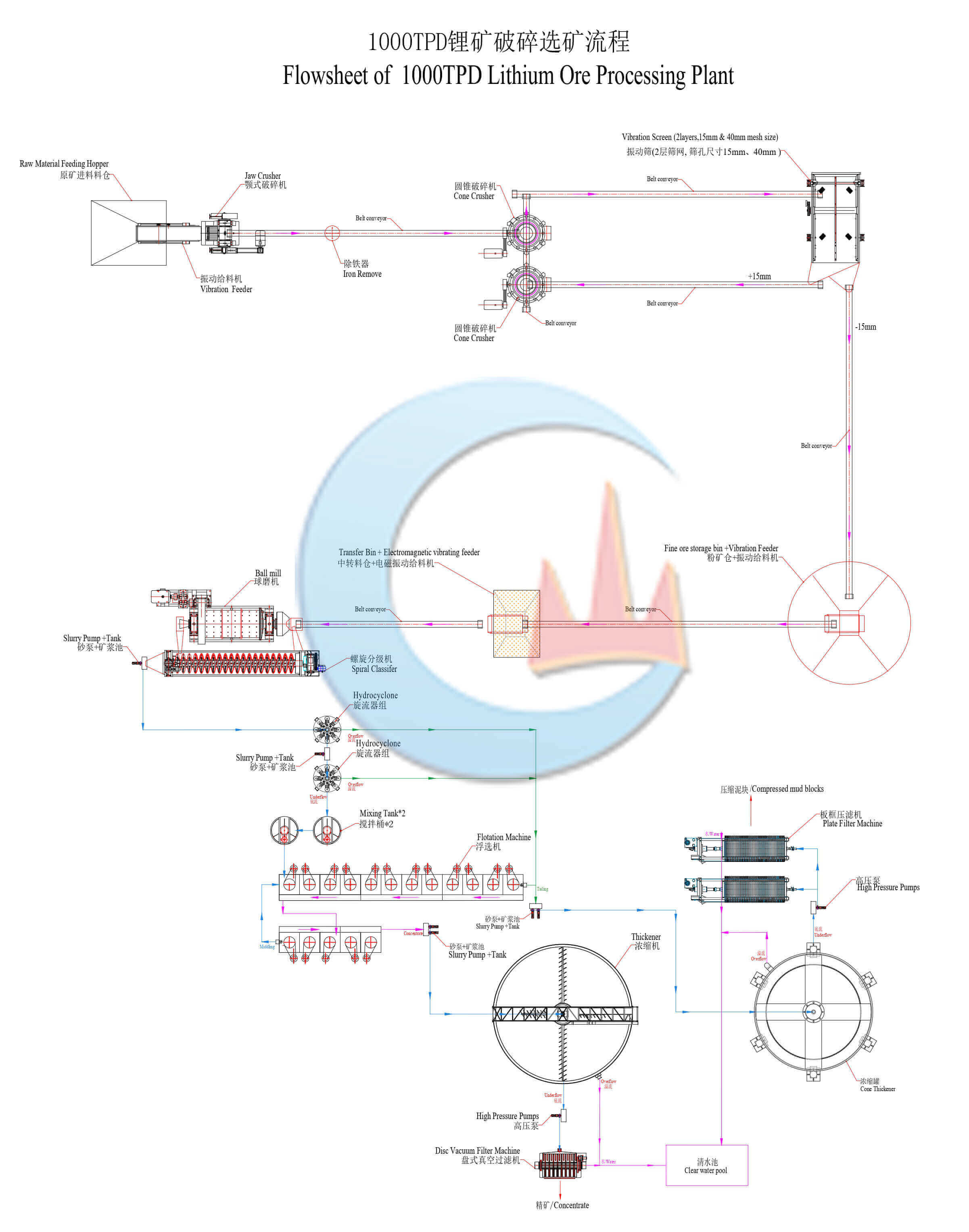

Lithium is an element valuable for the production of glass, aluminum products, and batteries. With the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has increased rapidly. Therefore, lithium ore is known as the “energy metal that drives the progress of the world”.

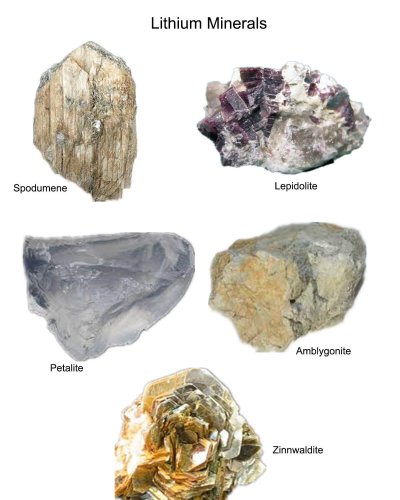

Lithium is mined from ores of petalite LiAl(Si2O5)2, lepidolite K(Li,Al)3(Al,Si,Rb)4O10(F,OH)2, spodumene LiAl(SiO3)2 and also subsurface brines.